Fouling-resistant antibacterial composite forward-osmosis membrane with positive surface charges and preparation method therefor

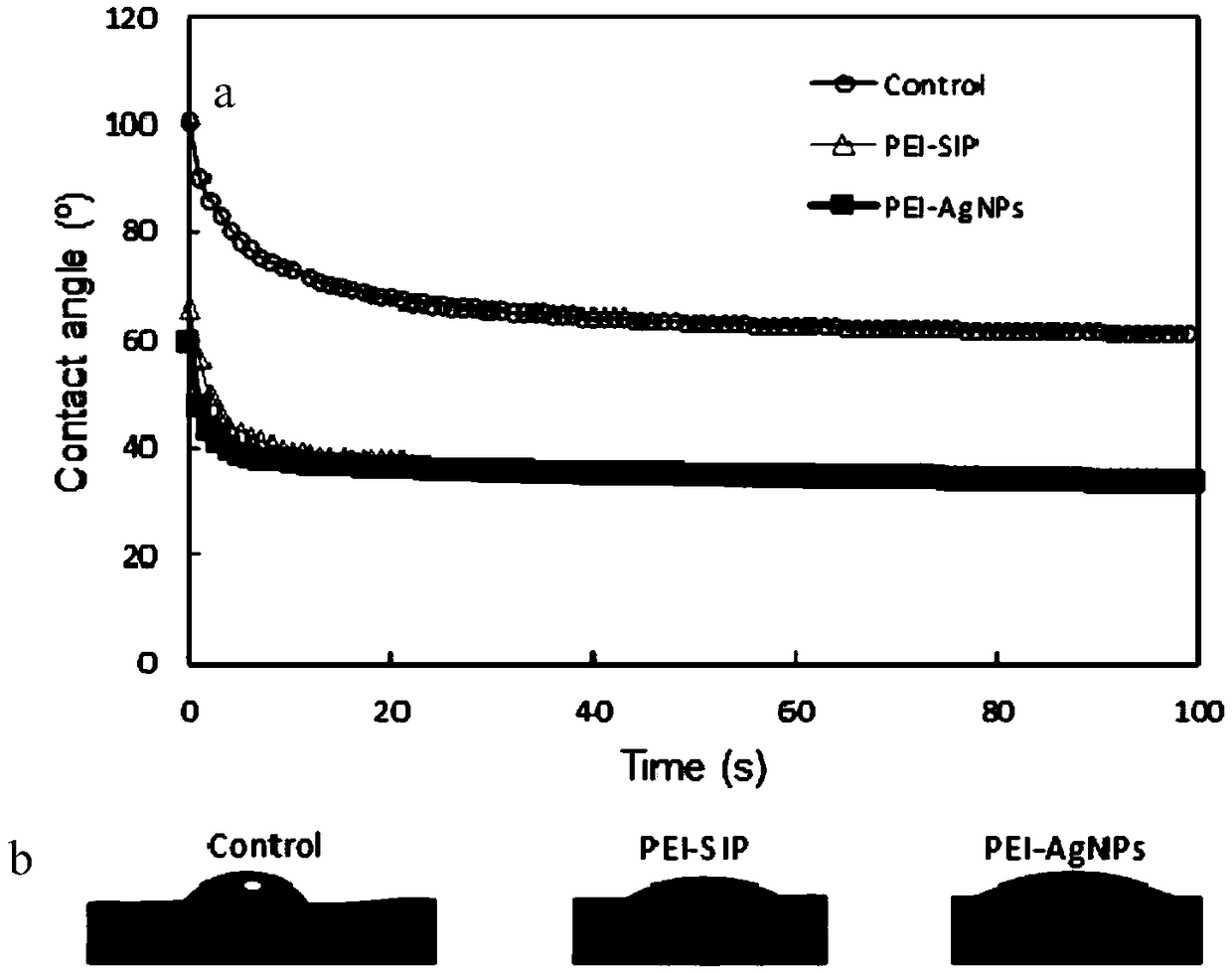

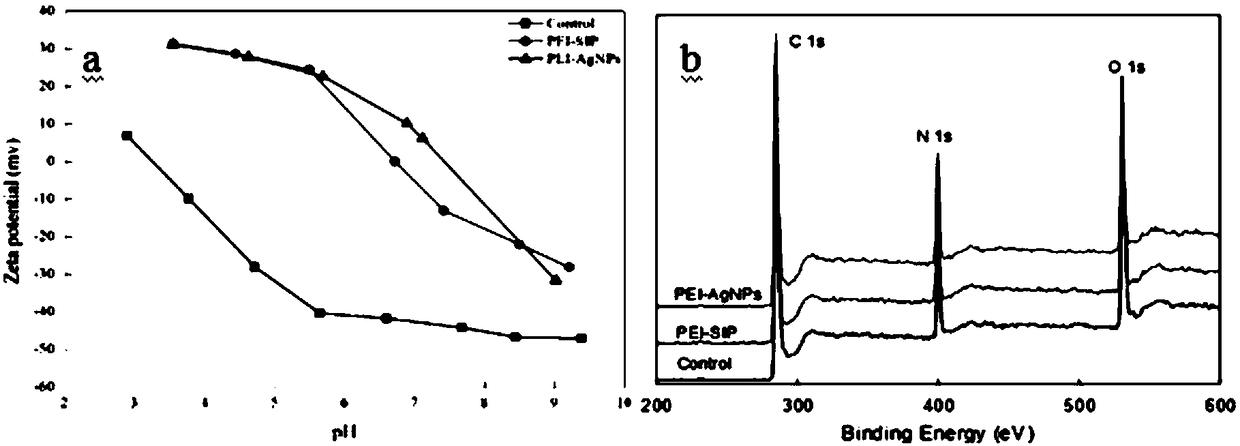

A forward osmosis membrane and anti-pollution technology, which is applied in semi-permeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve the problems of poor anti-pollution performance and inability to effectively inhibit bacterial growth and reproduction, and achieve High charge density, improved anti-biological fouling ability, and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

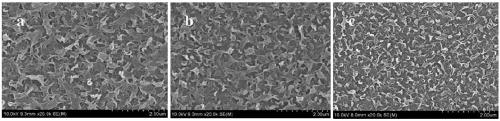

[0049] The preparation method of PEI graft modified film is:

[0050] 1) Polysulfone (Psf) is used as base membrane material, N,N-dimethylacetamide (DMAc) is used as organic solvent, and polyethylene glycol (PEG400) is used as porogen. Prepare the casting solution according to the mass ratio of Psf, DMAc, and PEG400 of 18:74:8, and form the casting solution after stirring at 65°C for 12 hours;

[0051] 2) The casting solution is left to stand for 24 hours, and defoaming: the defoaming temperature is 30°C.

[0052] 3) Prepare glass plate, scraper, thermometer, alcohol and alcohol cotton. Control the temperature of the glass plate and the scraper at 30° C. in an oven, clean the glass plate and the scraper, and adjust the thickness of the scraper (150 μm). Control air humidity to 40%-60%;

[0053] 4) Wipe the glass plate and scraper with alcohol cotton, pour the prepared film casting solution on the glass plate and scrape evenly, then quickly place it in a water bath at 30°C f...

Embodiment 2

[0058] The preparation method of PEI-AgNPs composite forward osmosis membrane is:

[0059] 1) Polysulfone (Psf) is used as base membrane material, N,N-dimethylacetamide (DMAc) is used as organic solvent, and polyethylene glycol (PEG400) is used as porogen. Prepare the casting solution according to the mass ratio of Psf, DMAc, and PEG400 of 18:74:8, and form the casting solution after stirring at 65°C for 12 hours;

[0060] 2) The casting solution is left to stand for 24 hours, and defoaming: the defoaming temperature is 30°C.

[0061] 3) Prepare glass plate, scraper, thermometer, alcohol and alcohol cotton. Control the temperature of the glass plate and the scraper at 30° C. in an oven, clean the glass plate and the scraper, and adjust the thickness of the scraper (150 μm). Control air humidity to 40%-60%;

[0062] 4) Wipe the glass plate and scraper with alcohol cotton, pour the prepared film casting solution on the glass plate and scrape to form a film, then quickly place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com