Preparation method and construction method of diatom ooze environment-friendly wall material for building decoration

A technology for environmental protection wall materials and architectural decoration, which is applied in the field of preparation of environmental protection wall materials, can solve the problems of discounted adsorption performance, easy to drop powder, easy to crack, etc., achieve the goal of improving adsorption capacity and purification effect, avoiding clogging, and improving construction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

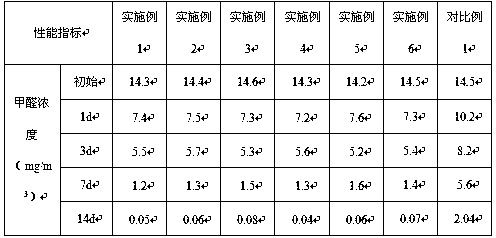

Examples

Embodiment 1

[0037] The specific process of preparation is:

[0038] (1) Sodium carbonate powder is loaded in the pores of diatomite by spray deposition; in the mixed system, by weight, there are 32 parts of sodium carbonate powder and 68 parts of diatomite;

[0039] (2) Add temperature-sensitive polyacrylic acid and sodium dodecylsulfonate into water to prepare capsule material emulsion; in the capsule material emulsion, by weight, 27 parts of temperature-sensitive polyacrylic acid, dodecyl sodium 1 part of sodium sulfonate, 72 parts of water;

[0040] (3) Add the diatomite and nano-ferrite solidly loaded with sodium carbonate powder prepared in step (1) to the capsule material emulsion prepared in step (2), and mix evenly to obtain a mixed solution; in the mixed solution, In parts by weight, wherein, 57 parts of diatomite loaded with sodium carbonate powder, 7 parts of nano-ferrite, and 36 parts of capsule emulsion;

[0041] (4) Drying the mixed solution obtained in step (3) at a const...

Embodiment 2

[0050] The specific process of preparation is:

[0051] (1) Sodium carbonate powder is loaded in the pores of diatomite by spray deposition; in the mixed system, by weight, 20 parts of sodium carbonate powder and 80 parts of diatomite;

[0052] (2) Add temperature-sensitive polyacrylic acid and sodium dodecylsulfonate into water to prepare capsule material emulsion; in the capsule material emulsion, by weight, 22 parts of temperature-sensitive polyacrylic acid, dodecyl sodium 1 part of sodium sulfonate, 77 parts of water;

[0053] (3) Add the diatomite and nano-ferrite solidly loaded with sodium carbonate powder prepared in step (1) to the capsule material emulsion prepared in step (2), and mix evenly to obtain a mixed solution; in the mixed solution, In parts by weight, wherein, 65 parts of diatomite loaded with sodium carbonate powder, 5 parts of nano-ferrite, and 30 parts of capsule material emulsion;

[0054] (4) Drying the mixed solution obtained in step (3) at a consta...

Embodiment 3

[0063] The specific process of preparation is:

[0064] (1) Sodium carbonate powder is loaded in the pores of diatomite by spray deposition; in the mixed system, by weight, 40 parts of sodium carbonate powder and 60 parts of diatomite;

[0065] (2) Add temperature-sensitive polyacrylic acid and sodium dodecylsulfonate into water to prepare capsule material emulsion; in the capsule material emulsion, by weight, 30 parts of temperature-sensitive polyacrylic acid, dodecyl sodium 2 parts of sodium sulfonate, 68 parts of water;

[0066] (3) Add the diatomite and nano-ferrite solidly loaded with sodium carbonate powder prepared in step (1) to the capsule material emulsion prepared in step (2), and mix evenly to obtain a mixed solution; in the mixed solution, In parts by weight, wherein, 50 parts of diatomite loaded with sodium carbonate powder, 10 parts of nano-ferrite, and 40 parts of capsule material emulsion;

[0067] (4) Drying the mixed solution obtained in step (3) at a cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com