Block copolyester and preparation method thereof, and barrier film and barrier bottle

A technology of block copolyester and polyethylene terephthalate, applied in the field of materials, can solve problems such as limiting the scope of application, and achieve the effect of excellent oxygen and carbon dioxide barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a kind of preparation method of the block copolyester of formula (I) structure, comprising:

[0031] Polyethylene furandicarboxylate, polyethylene terephthalate, transesterification catalyst, stabilizer and antioxidant mixed reaction, obtain the block copolyester of formula (I) structure;

[0032]

[0033] Wherein, m is 20-200; preferably 50-150; n is 20-200; preferably 50-150; z is 10-200;

[0034] According to the present invention, the intrinsic viscosity of the block copolyester is preferably 0.45-1.0 dL / g; more preferably 0.48-0.9 dL / g; most preferably 0.55-0.85 dL / g.

[0035] The present invention at first provides the polyethylene furandicarboxylate of formula (II) structure and the polyethylene terephthalate of formula (III) structure; The present invention does not limit to its source, can be commercially available, also It can be prepared according to conventional methods in the prior art. The inventor does not limit this. ...

Embodiment 1

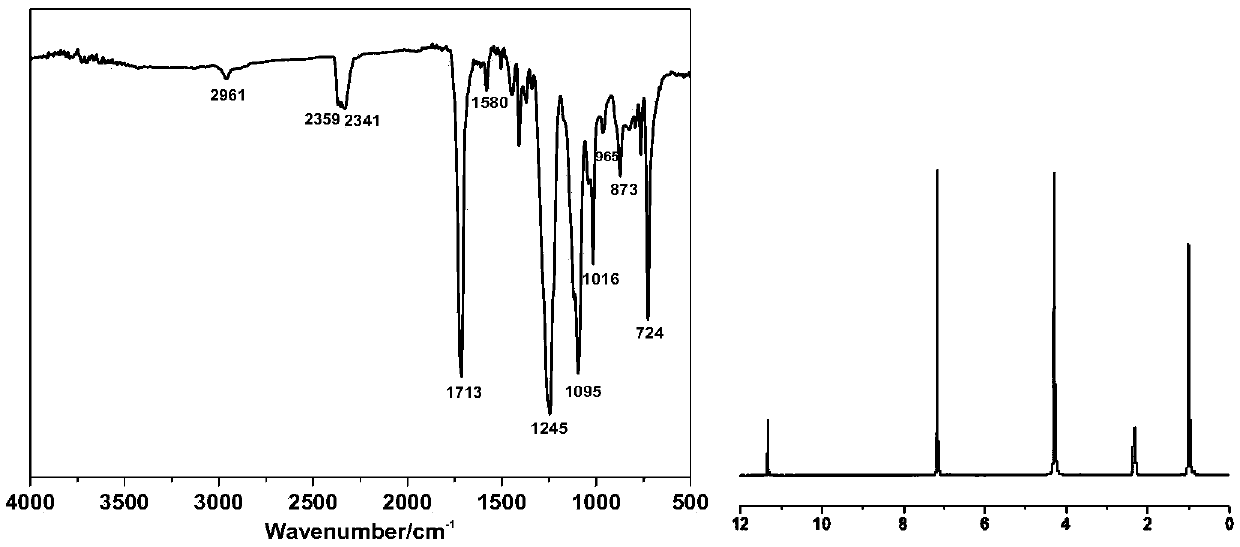

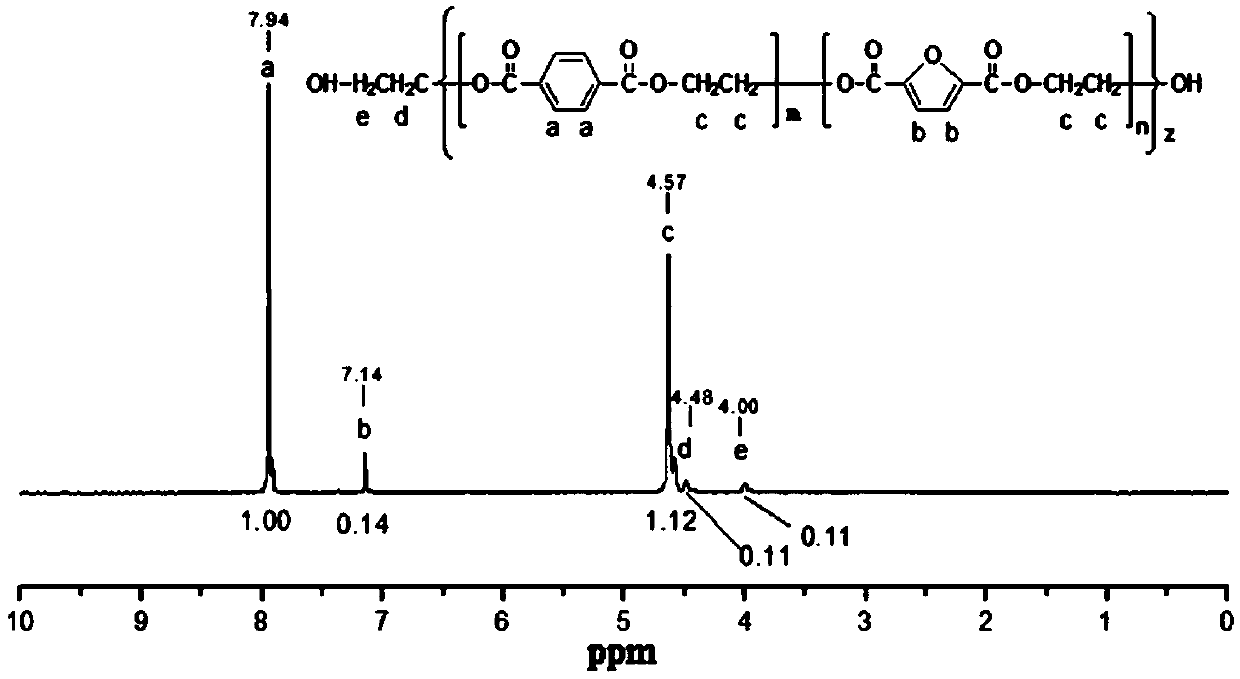

[0071] Add polyethylene furandicarboxylate with a degree of polymerization of 100, polyethylene terephthalate with a degree of polymerization of 150, and antimony trioxide into a 1000mL reactor at a molar ratio of 0.2:0.8:0.002, and add a stable agent and antioxidant, and gradually raised the temperature to 275°C, and controlled the vacuum degree below 200Pa to react for 3 hours to obtain polyfurandicarboxylic acid terephthalate block copolyester with an intrinsic viscosity of 0.76dL / g, FT-IR and 1 H-NMR spectrum such as figure 2 with image 3 as shown, figure 2 The FT-IR spectrum of the polyfurandicarboxylic acid terephthalate block copolyester obtained in Example 1 of the present invention; image 3 It is the 1H-NMR spectrum of the polyfurandicarboxylic acid terephthalate block copolyester obtained in Example 1 of the present invention. Through melt molding, a transparent film with a thickness of 100-200 μm is prepared, such as figure 1 as shown, figure 1 The photo of...

Embodiment 2

[0073] Add polyethylene furandicarboxylate with a degree of polymerization of 80, polyethylene terephthalate with a degree of polymerization of 160, and antimony trioxide into a 1000mL reactor at a molar ratio of 0.95:0.05:0.003, and add a stable agent and antioxidant, and gradually raise the temperature to 255°C, and control the vacuum degree below 200Pa to react for 3 hours to obtain polyfurandicarboxylic acid terephthalate block copolyester with an intrinsic viscosity of 0.80dL / g, which is formed by melt molding , to prepare a transparent film with a thickness of 100-200 μm, and the oxygen gas barrier property is 0.010×10 -10 cm 3 cm / cm 2 ·s·cmHg, carbon dioxide gas barrier property is 0.018×10 - 10 cm 3 cm / cm 2 ·s·cmHg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com