Preparation method of three-dimensional composite metal lithium anode all-solid-state lithium ion batteries

A lithium-ion battery and three-dimensional composite technology, applied in the field of electrochemical power sources, can solve the problems of poor conductivity interface layer, soft and low melting point physical properties of lithium metal, rapid scale application and high temperature safety problems, etc., to achieve electrode interface Stability, improved life and cycle performance, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

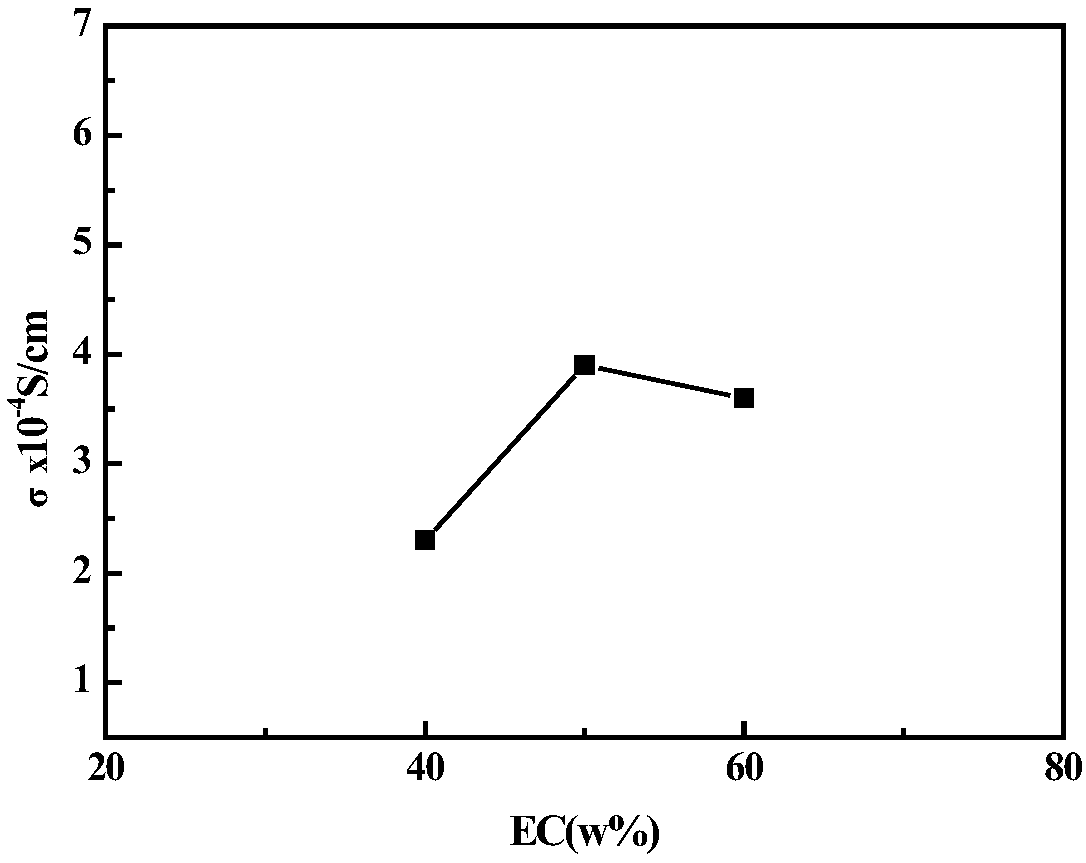

[0059] The difference with Comparative Example 3 is that plasticizer EC (ethylene carbonate) was added, and 800mg PMMA and 200mgPEI were weighed and dissolved in 50ml of DMF (slowly added to prevent the PMMA agglomeration from being difficult to dissolve due to too fast addition), ultrasonic After dispersing for 30 minutes, under the constant temperature condition of 85° C., magnetic heating and stirring for 20 hours, a PMMA-PEI copolymer solution was obtained. Then weigh 34mgLiPF 6 , 400mg EC and 150mg Al 2 o 3 Add it into the mixed solution, stir at room temperature for 60 min, and react with heating and stirring at a constant temperature of 50° C. for 3 h after the reactants are uniformly mixed. A milky white transparent gel-like product was obtained, and the product was uniformly coated on a PTFE plate, dried at 80° C. under vacuum for 36 hours, and then released from the mold to obtain a white all-solid-state electrolyte film with a smooth surface.

Embodiment 2

[0061] The difference with Comparative Example 3 is that plasticizer EC (ethylene carbonate) was added, and 800mg PMMA and 200mgPEI were weighed and dissolved in 50ml of DMF (slowly added to prevent the PMMA agglomeration from being difficult to dissolve due to too fast addition), ultrasonic After dispersing for 30 minutes, under the constant temperature condition of 85° C., magnetic heating and stirring for 20 hours, a PMMA-PEI copolymer solution was obtained. Then weigh 34mgLiPF 6 , 500mg EC and 150mg Al 2 o 3 Add it into the mixed solution, stir at room temperature for 60 min, and react with heating and stirring at a constant temperature of 50° C. for 3 h after the reactants are uniformly mixed. A milky white transparent gel-like product was obtained, and the product was uniformly coated on a PTFE plate, dried at 80° C. under vacuum for 36 hours, and then released from the mold to obtain a white all-solid-state electrolyte film with a smooth surface.

Embodiment 3

[0063] The difference with Comparative Example 3 is that plasticizer EC (ethylene carbonate) was added, and 800mg PMMA and 200mgPEI were weighed and dissolved in 50ml of DMF (slowly added to prevent the PMMA agglomeration from being difficult to dissolve due to too fast addition), ultrasonic After dispersing for 30 minutes, under the constant temperature condition of 85° C., magnetic heating and stirring for 20 hours, a PMMA-PEI copolymer solution was obtained. Then weigh 34mgLiPF 6 , 600mg EC and 150mg Al 2 o 3 Add it into the mixed solution, stir at room temperature for 60 min, and react with heating and stirring at a constant temperature of 50° C. for 3 h after the reactants are uniformly mixed. A milky white transparent gel-like product was obtained, and the product was uniformly coated on a PTFE plate, dried at 80° C. under vacuum for 36 hours, and then released from the mold to obtain a white all-solid-state electrolyte film with a smooth surface.

[0064] The test of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com