Biological antibacterial material for medical catheter and preparation method

An antibacterial material and biological technology, applied in the field of medical materials, can solve the problems of obvious foreign body sensation, poor biocompatibility, poor antibacterial performance, etc., to prevent foreign body sensation, improve biocompatibility, and increase self-lubricating smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

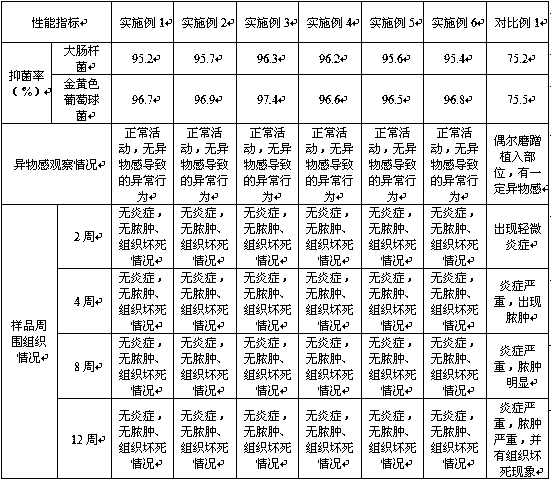

Examples

Embodiment 1

[0032] The preparation process is:

[0033] (1) Mixing silicone, graphene, and medicine, so that silicone and graphene are closely combined to obtain a self-lubricating material; the medicine is a composition of antibacterial agent, analgesic, and anti-inflammatory agent; the mixing rotor speed is 46r / min, the mixing time is 16min; in the self-lubricating material, 7 parts by weight of silicone, 4 parts by weight of graphene, and 0.5 parts by weight of drug;

[0034] (2) Knead and mix soybean protein, dialdehyde polysaccharide crosslinking agent and plasticizer evenly, add the self-lubricating material prepared in step (1), then add polycaprolactone and silicone rubber, knead evenly, and extrude to make Granules, made of self-lubricating biological antibacterial material pellets; plasticizer is mannitol; silicone rubber is methyl silicone rubber; kneading fast paddle speed is 33r / min, slow paddle speed is 24r / min, kneading time is 13min The rotor speed of mixing is 69r / min, a...

Embodiment 2

[0037] The preparation process is:

[0038] (1) Mixing silicone, graphene, and medicine, so that silicone and graphene are closely combined to obtain a self-lubricating material; the medicine is a composition of antibacterial agent, analgesic, and anti-inflammatory agent; the mixing rotor speed is 42r / min, the mixing time is 16min; in the self-lubricating material, 6 parts by weight of silicone, 4 parts by weight of graphene, and 0.9 parts by weight of drug;

[0039] (2) Knead and mix soybean protein, dialdehyde polysaccharide crosslinking agent and plasticizer evenly, add the self-lubricating material prepared in step (1), then add polycaprolactone and silicone rubber, knead evenly, and extrude to make Granules, made of self-lubricating biological antibacterial material pellets; plasticizer is monoglyceride; silicone rubber is methyl vinyl silicone rubber; kneading fast paddle speed is 31r / min, slow paddle speed is 23r / min, kneading time is 13min; the rotor speed of mixing is ...

Embodiment 3

[0042] The preparation process is:

[0043] (1) Mixing silicone, graphene, and medicine, so that silicone and graphene are closely combined to obtain a self-lubricating material; the medicine is a composition of antibacterial agent, analgesic, and anti-inflammatory agent; the mixing rotor speed is 48r / min, the mixing time is 16min; in the self-lubricating material, 8 parts by weight of silicone, 5 parts by weight of graphene, and 0.8 parts by weight of drug;

[0044] (2) Knead and mix soybean protein, dialdehyde polysaccharide crosslinking agent and plasticizer evenly, add the self-lubricating material prepared in step (1), then add polycaprolactone and silicone rubber, knead evenly, and extrude to make Granules, obtained self-lubricating biological antibacterial material pellets; Plasticizer is mannitol; Silicone rubber is methyl vinyl phenyl silicone rubber; The fast paddle speed of kneading is 34r / min, and the slow paddle speed is 27r / min, The kneading time is 9min; the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com