Excimer laser oscillation device having gas recycle function

A technology of excimer laser and oscillation device, which is applied in the direction of laser monitoring device, test gas existence, laser, etc., can solve the problem of not having circulation function and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

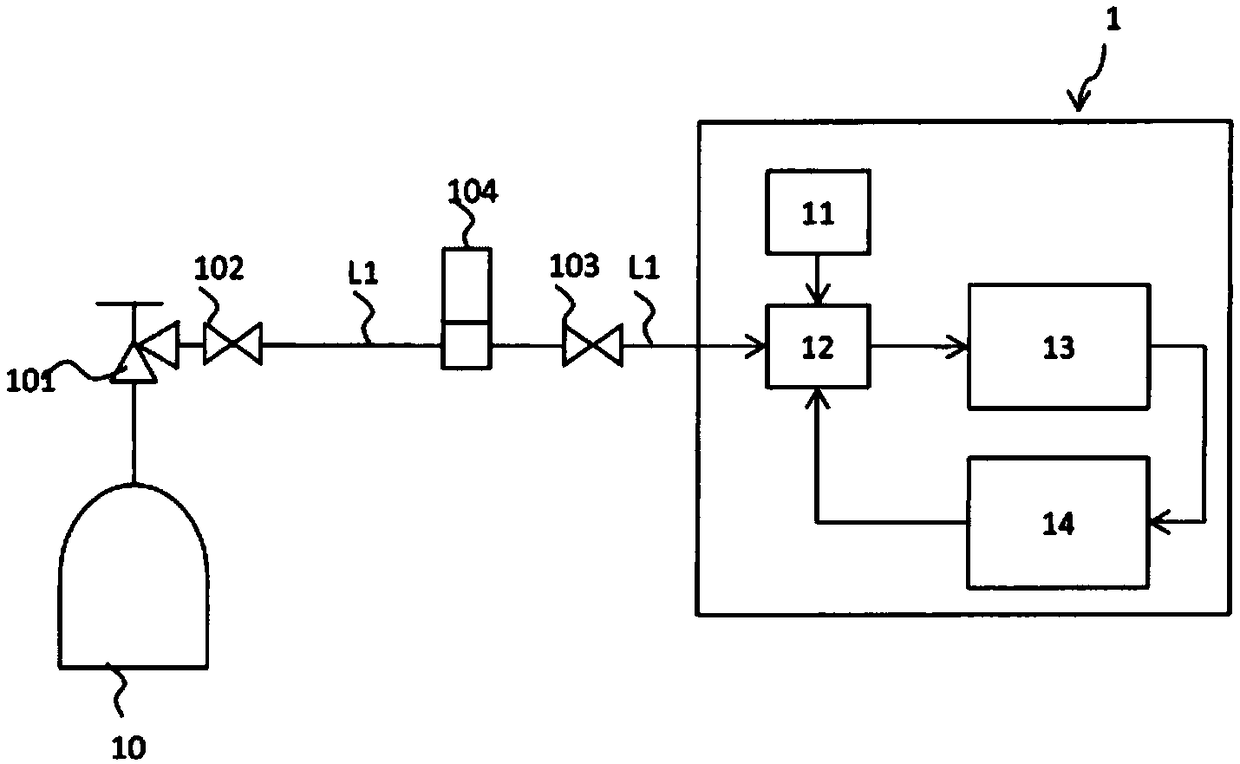

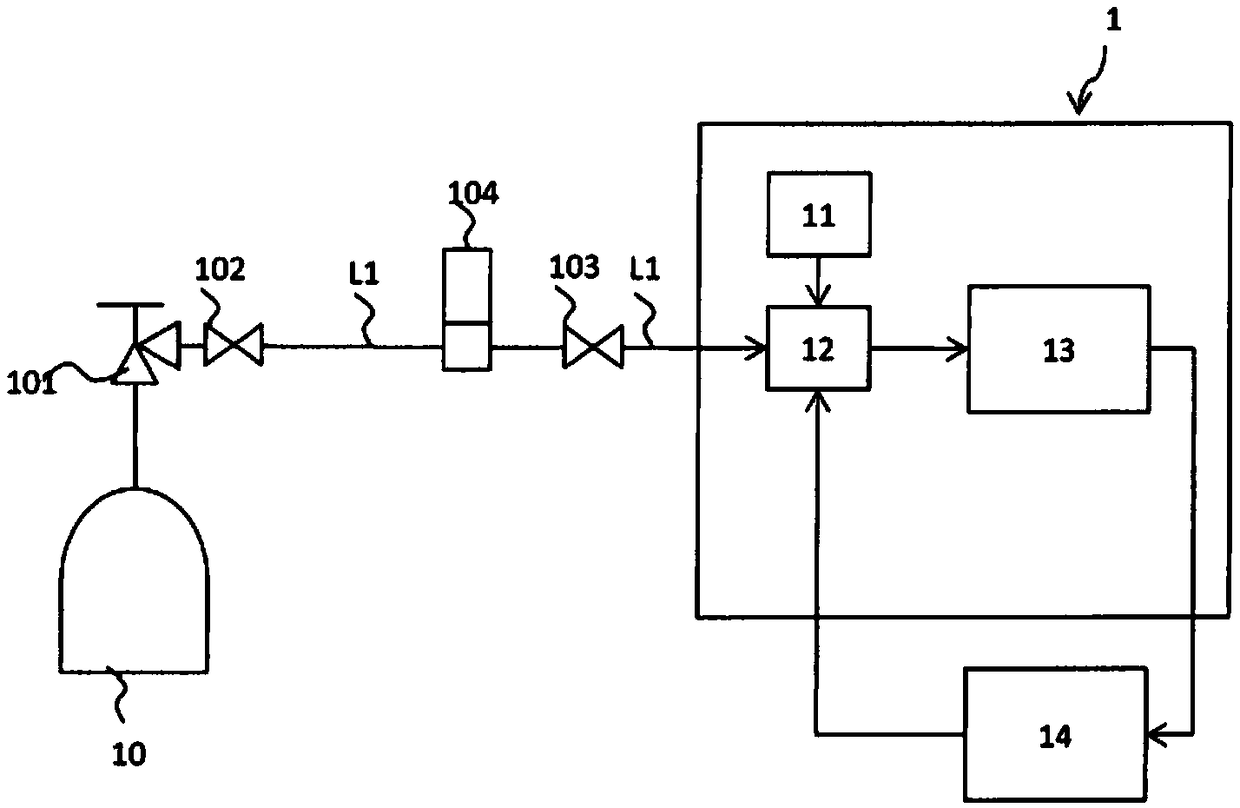

[0180] use Figure 1A , 1B The excimer laser oscillator 1 according to Embodiment 1 will be described.

[0181]The excimer laser oscillator is, for example, a krypton-fluorine (KrF) excimer laser oscillator, an argon-fluorine (ArF) excimer laser oscillator, or an argon-xenon-fluorine (Ar / X·F) excimer laser oscillator.

[0182] The excimer laser oscillator 1 of Embodiment 1 is provided in the system of the excimer laser oscillator 1: the interior is filled with a halogen gas (such as fluorine), a rare gas (such as krypton, argon, xenon), a buffer gas ( For example, an oscillation chamber 12 of laser gas such as neon, helium, and chlorine; a first impurity removal device 13 that removes impurities in exhaust gas discharged from the oscillation chamber 12; A second impurity removal device 14 for removing impurities from the purified gas.

[0183] The oscillation chamber 12 is filled with a predetermined pressure and a predetermined amount of laser gas. In this state, the high-...

Embodiment approach 2

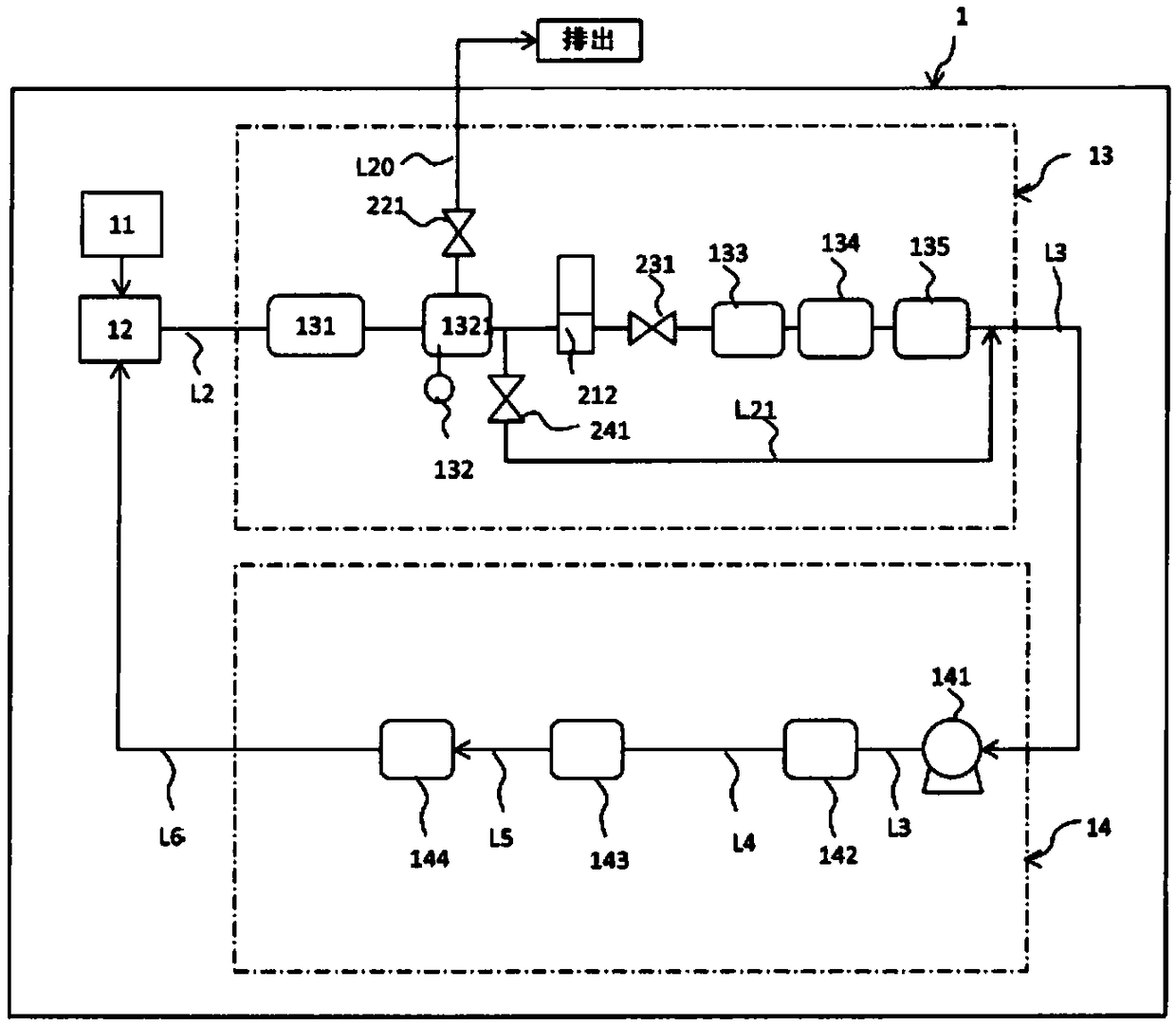

[0228] use Figure 2A , 2B An excimer laser oscillator 1 according to Embodiment 2 will be described. For the same structure as that of Embodiment 1, description thereof will be omitted or simplified. The excimer laser oscillation device 1 of Embodiment 2 is, for example, Figure 2A As shown, the first impurity removal device 13 is provided in the system, and the second impurity removal device 14 is arranged outside the system.

[0229] Such as Figure 2B As shown, the second impurity removal device 14 (compressor 141 , first removal unit 142 , second removal unit 143 , purified gas buffer tank 144 ) is arranged outside the system of the excimer laser oscillator 1 .

Embodiment approach 3

[0231] use image 3 An excimer laser oscillator according to Embodiment 3 will be described. Descriptions of the same configurations as those in Embodiments 1 and 2 are sometimes omitted or simplified. The difference from Embodiments 1 and 2 is that the structure of the second impurity removing device 14 has a xenon gas removing unit 70 and an auxiliary xenon gas supply function. When the xenon gas in the exhaust gas is removed and used as a laser gas component, the second impurity can be easily removed by the second removal unit 143. That is, the second impurity removing device 14 may be arranged inside or outside the system of the excimer laser oscillator.

[0232] The xenon gas removal unit 70 is arranged in the subsequent stage of the first removal unit 142 to remove xenon gas. The xenon removal unit 70 is a xenon removal device filled with activated carbon. The purified gas that has passed through the xenon removal unit 70 is sent to the second removal unit 143.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com