A heat-resistant steel volute sprue slag-retaining and shrinkage-feeding process

A technology of heat-resistant steel and volute, which is applied in the technical field of heat-resistant steel volute sprue slag blocking and shrinkage feeding, which can solve the problems of difficult forming and easy oxidation of molten steel, so as to improve the process yield and avoid non-forming , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

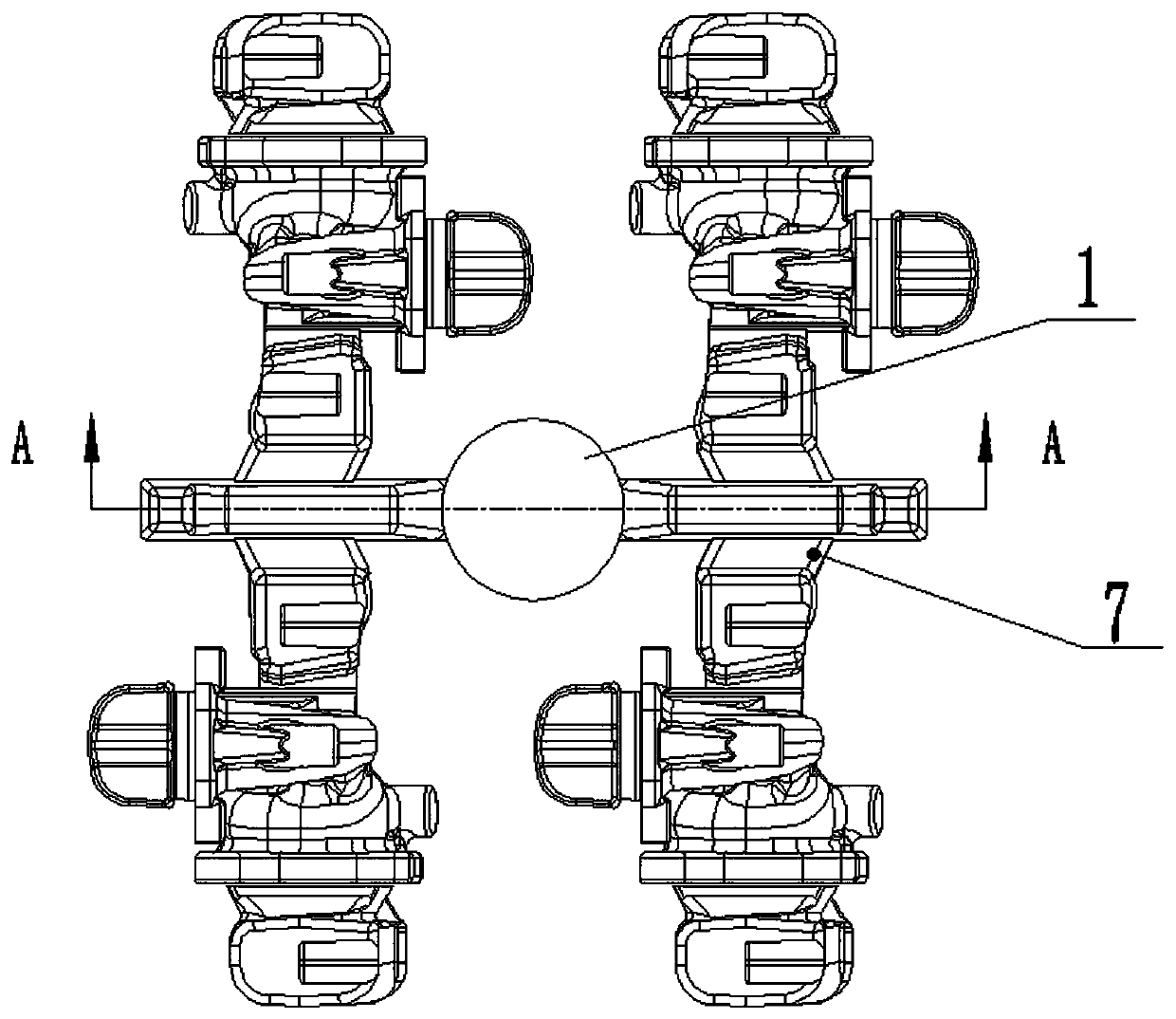

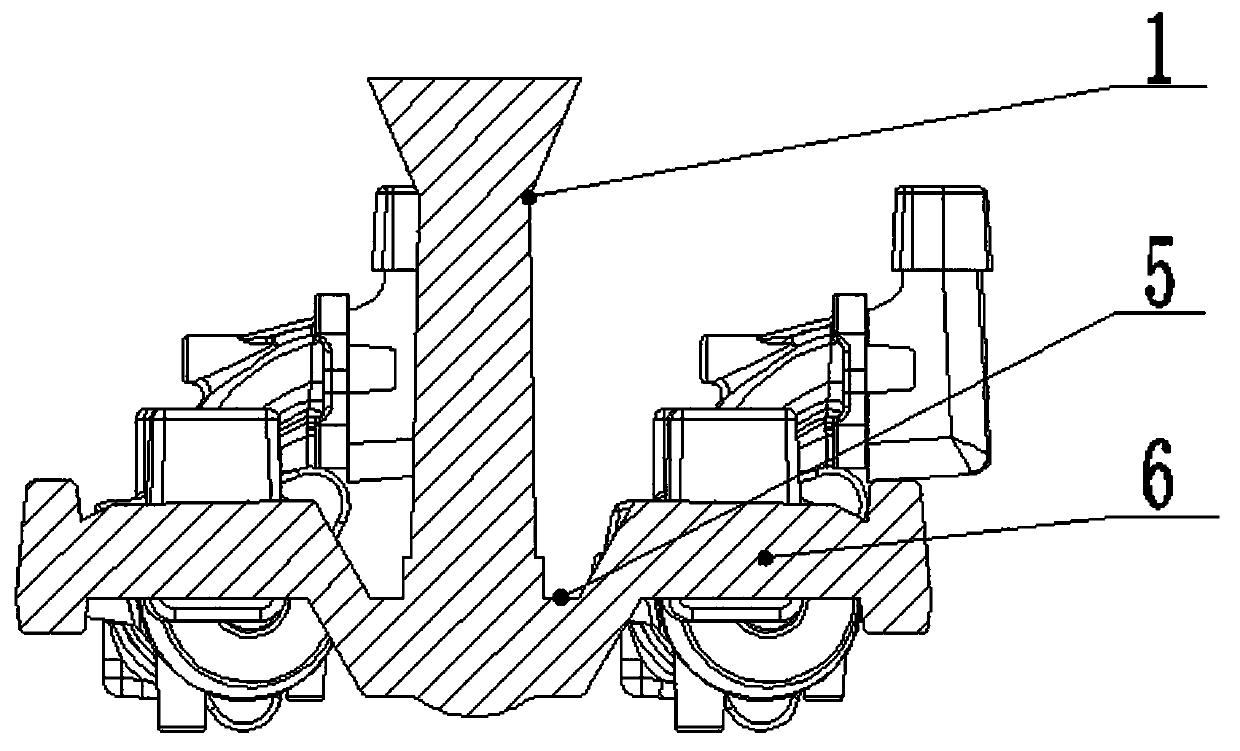

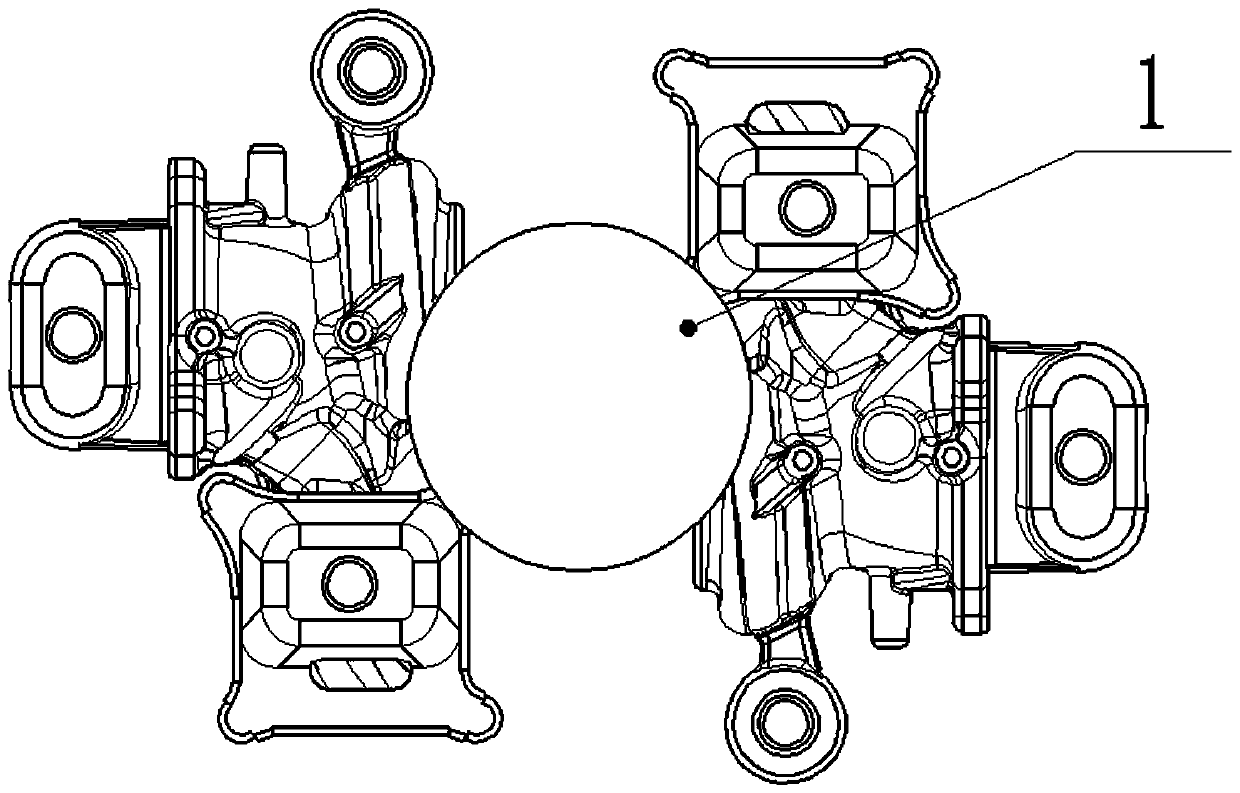

[0029] Such as image 3 with Figure 4 As shown, a heat-resistant steel volute runner includes sprue 1, in which a filter 2 is placed on the upper section of the sprue 1, an "eight" type contraction 3 is set in the middle of the sprue 1, and the lower section of the sprue 1 is set Feeding riser neck 4.

[0030] The slag retaining and feeding process of heat-resistant steel scroll runner includes the following steps:

[0031] (1) Determine the cross-sectional ratio of sprue 1, filter 2 and "eight" type contraction 3, namely F straight : F filter : F Hinder =1: 4: 0.8;

[0032] (2) Determine the filling time of the gating system:

[0033]

[0034] Among them: G is the total weight of molten steel in the mold, including the weight of the pouring riser system;

[0035] (3) Determine the cross-sectional area of each gating system according to the Ozan formula:

[0036]

[0037] Among them: ρ is the density of molten steel, μ is the flow loss coefficient, g is the acceleration due to gr...

Embodiment 2

[0042] In Example 2, G is 40kg, t is 6.1s, Hp is 31cm, and ρ is 0.0076Kg / cm 3 , G is 981cm / S 2 , Μ is 0.35, after calculation, F in this embodiment straight 13.1cm 2 , F filter 52.5cm 2 , F Hinder 10.5cm 2 .

Embodiment 3

[0044] In Example 3, G is 45kg, t is 6.3s, Hp is 31cm, and ρ is 0.0076Kg / cm 3 , G is 981cm / S 2 , Μ is 0.35, after calculation, F in this embodiment straight 14.3cm 2 , F filter 57cm 2 , F Hinder 11.4cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com