Method for rapidly preparing one-dimensional linear welding point of Cu6Sn5 intermetallic compound at low temperature

An intermetallic compound and linear welding technology, which is applied in metal processing equipment, welding media, manufacturing tools, etc., can solve the problems of long solder joint formation time, complicated preparation process, and high welding temperature, and achieve shortened preparation time, simple process, The effect of omitting process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

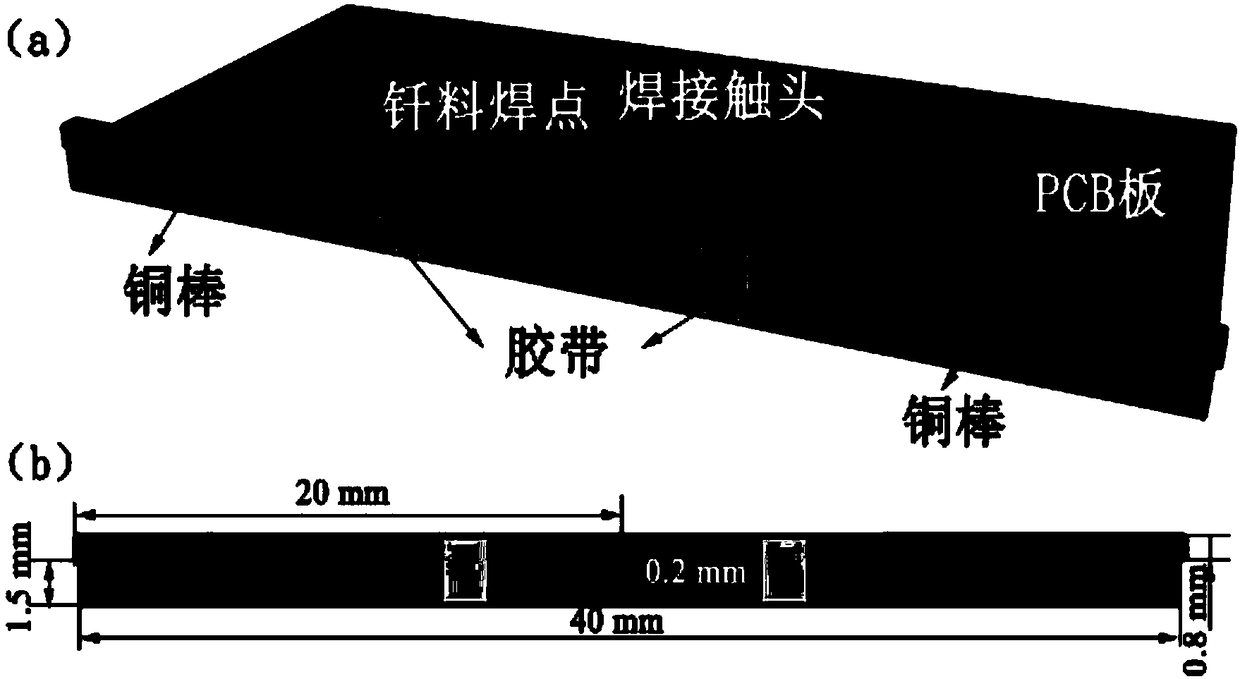

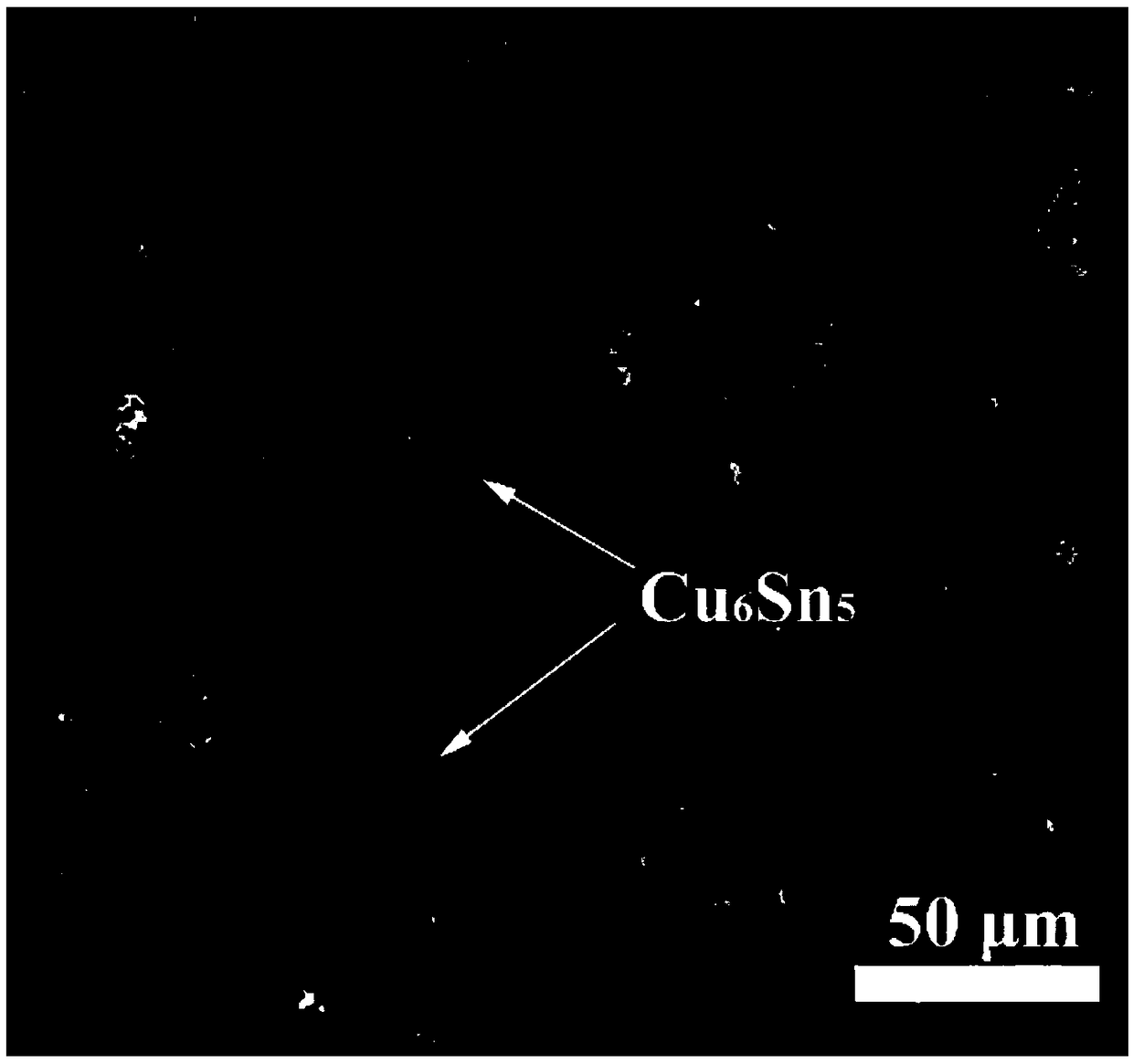

[0025] Example 1: Combining the following Figure 1-3 Embodiments of the present invention will be described in detail.

[0026] 1. Cut copper with a purity greater than 99.99wt.% into copper rods with a size of 800μm×800μm×20mm by wire cutting;

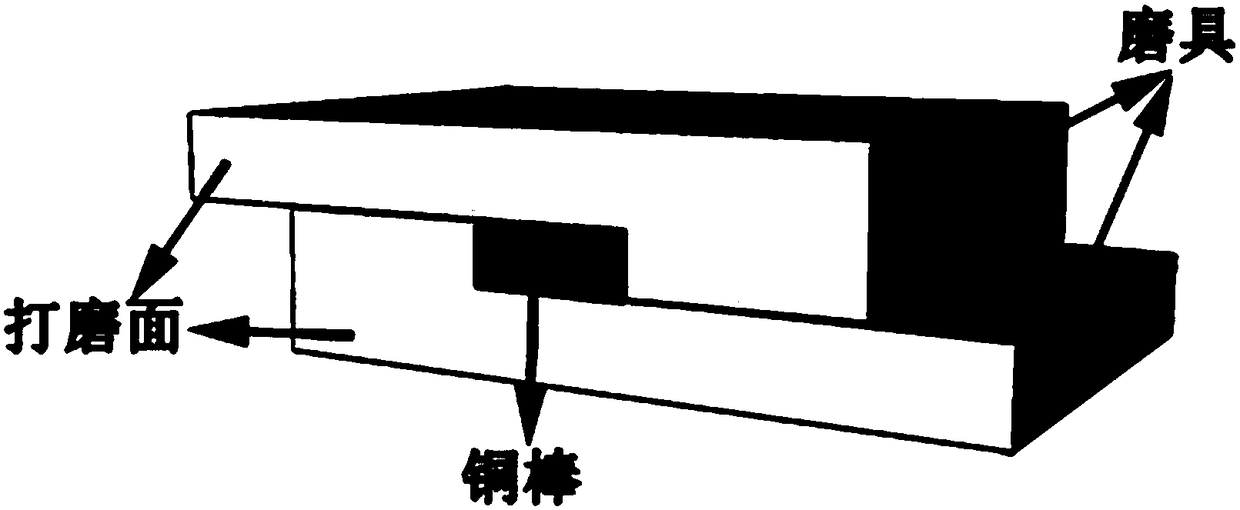

[0027] 2. Use No. 2000 sandpaper to polish the copper rod used in the experiment, combine figure 1 ;

[0028] 3. Put the polished copper rod into acetone solution and 30vol.% nitric acid aqueous solution for ultrasonic cleaning for 8 minutes to remove organic pollutants and oxides on the surface of the copper rod, then take out the copper rod and put it into ethanol solution Wash and dry in

[0029] 4. Weigh 5g of Sn-3.5Ag Lead-free solder paste, the solder paste is composed of alloy and flux, and the flux uses ALPHA FLUX flux. The percentage of SnAg alloy in the solder paste is about 87.4wt.%, m 1 =4.37g, the flux accounts for about 12.6wt.%, m 2 =0.63g; if the composite solder paste is Sn-3.5Ag-10wt.%Cu, the mass percentage...

example 2

[0037] Example 2: The following specifically sets forth the implementation mode of the present invention,

[0038] Combining the following Figure 4 Embodiments of the present invention will be described. Example 2 is basically the same as the implementation steps 1-3 and steps 5-7 of example 1, except that in step 4, the mass percentage of copper in the composite solder solder paste is 25wt.%, and the specific implementation methods are as follows:

[0039] 1. Weigh 5g of Sn-3.5Ag Lead-free solder paste, the solder paste is composed of alloy and flux, and the flux uses ALPHA FLUX flux. The percentage of SnAg alloy in the solder paste is about 87.4wt.%, m 1 =4.37g, the flux accounts for about 12.6wt.%, m 2 =0.63g; if the composite solder paste is Sn-3.5Ag-10wt.%Cu, the mass percentage of copper powder is 25wt.%, and the mass of copper powder to be added is m 5 =1.46g, in order to ensure that the percentage of the SnAg-Cu alloy in the composite solder paste remains unchange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com