Synthetic method of cesium tungstate nano particles

A nanoparticle and synthesis method technology, which is applied in the field of synthesis of cesium tungstate nanoparticles, can solve the problems of high energy consumption for synthesis, poor powder dispersion, and high requirements for reaction equipment, and achieve mild reaction conditions, low reaction temperature, and strong absorption. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Add 0.352g tungsten carbonyl, 0.665g oxidizing agent and 4mL oleylamine to a 50mL four-necked round bottom flask;

[0042] (2) Heating the solution in (1) to 180°C under the protection of an inert gas. During the heating process, the solution first turns yellow and then turns green. When the temperature reaches 180°C, the solution becomes colorless;

[0043] (3) At this point, quickly inject 2.8 mL of the prepared ammonium oleate octadecene solution into the round-bottomed flask with a syringe, and continue heating to 250° C.;

[0044] (4) After reacting for 3 hours, the container containing the reaction solution was placed in a mixture of ice and water and rapidly cooled to room temperature to quench the reaction and obtain a dark blue solution.

[0045] (5) Add 10 mL of ethanol to the above solution to precipitate the nanoparticles, and cesium tungstate nanoparticles can be obtained after centrifugation.

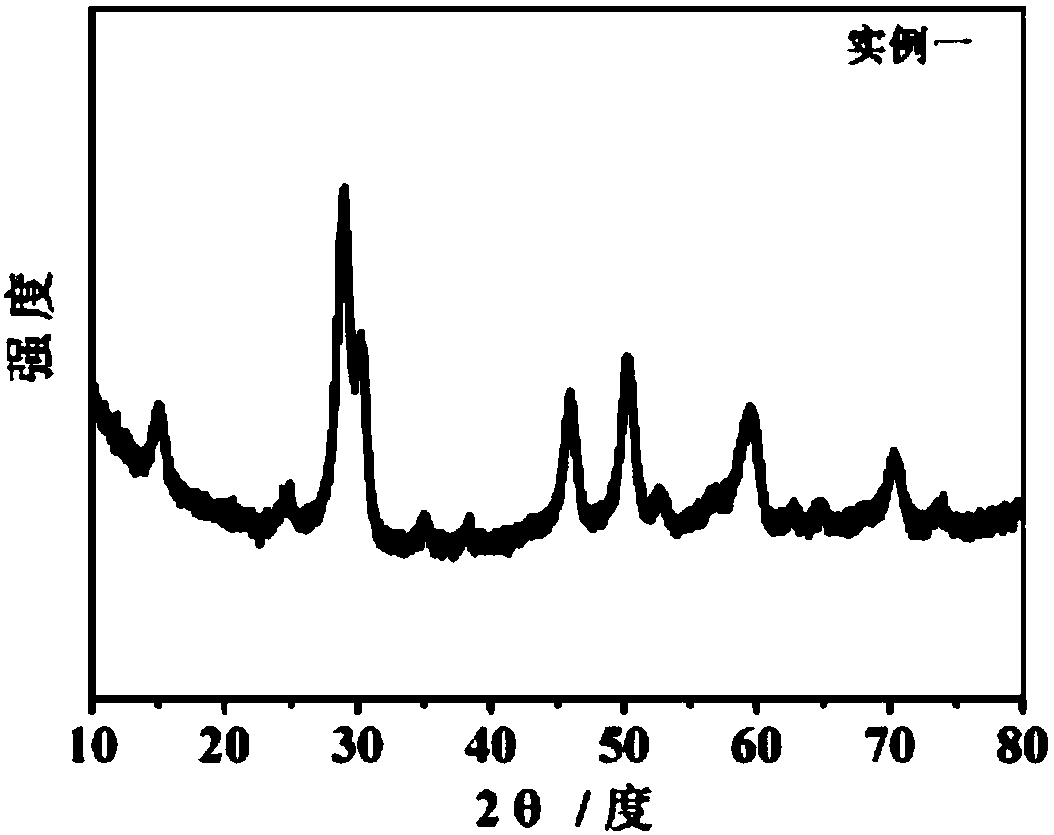

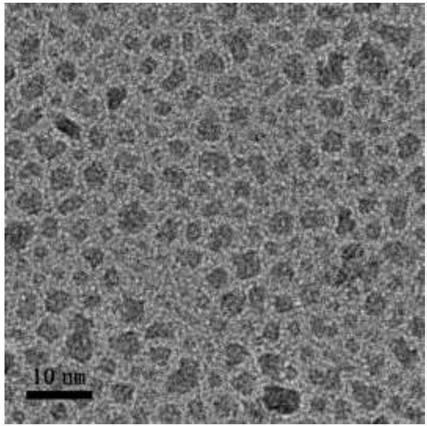

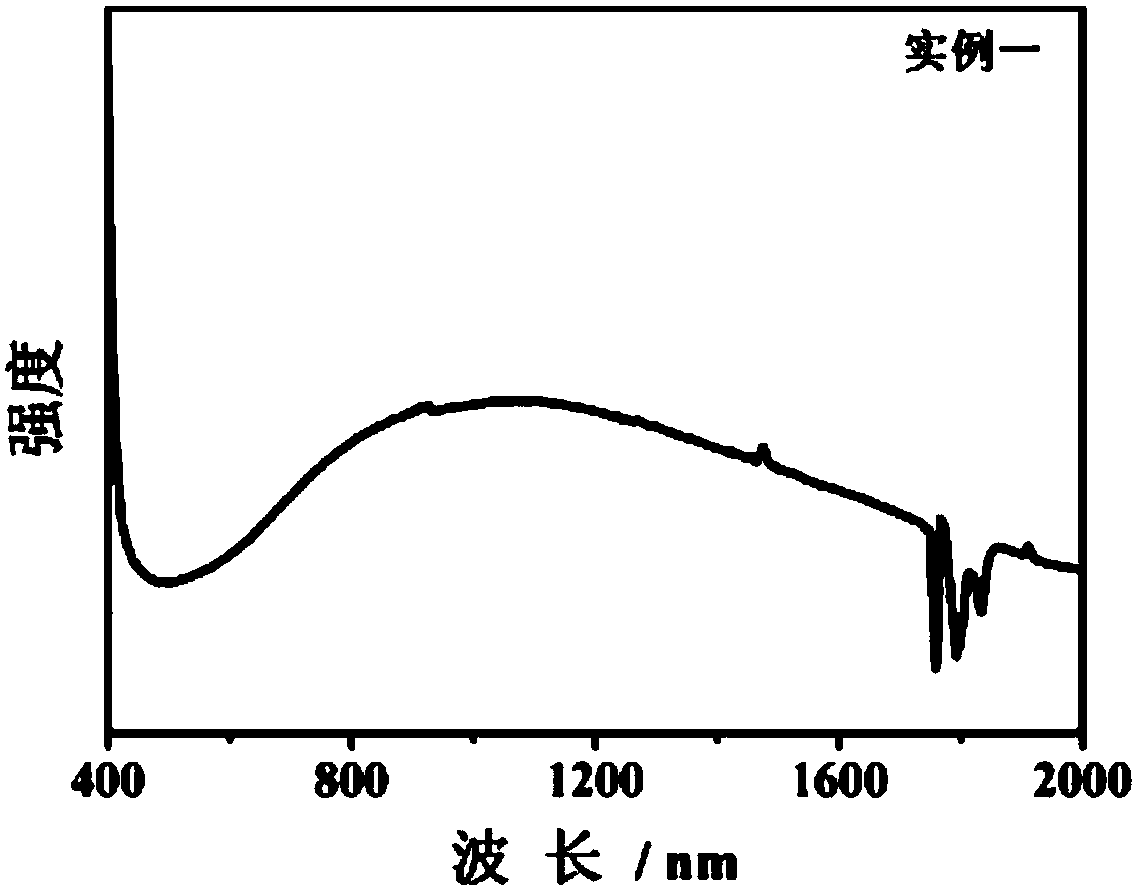

[0046] The crystal structure of the synthesized cesium tu...

Embodiment 2

[0050] (1) Add 0.352g tungsten carbonyl, 0.665g oxidizing agent and 4mL oleylamine to a 50mL four-necked round bottom flask;

[0051] (2) Heating the solution in (1) to 180°C under the protection of an inert gas. During the heating process, the solution first turns yellow and then turns green. When the temperature reaches 180°C, the solution becomes colorless;

[0052] (3) At this point, quickly inject 2.8 mL of the prepared ammonium oleate octadecene solution into the round-bottomed flask with a syringe, and continue heating to 290° C.;

[0053] (4) After reacting for 3 hours, the container containing the reaction solution was placed in a mixture of ice and water and rapidly cooled to room temperature to quench the reaction and obtain a dark blue solution.

[0054] (5) Add 10 mL of ethanol to the above solution to precipitate the nanoparticles, and cesium tungstate nanoparticles can be obtained after centrifugation.

[0055] The crystal structure of the synthesized cesium tu...

Embodiment 3

[0059] (1) Add 0.352g tungsten carbonyl, 0.665g oxidizing agent and 8mL oleylamine to a 50mL four-necked round bottom flask;

[0060] (2) Under the condition of inert gas protection, the solution in (1) is first heated to 160°C. During the heating process, the solution first turns yellow, then turns green, and when the temperature reaches 180°C, the solution becomes colorless;

[0061] (3) At this point, quickly inject 2.8 mL of the prepared ammonium oleate octadecene solution into the round-bottomed flask with a syringe, and continue heating to 270° C.;

[0062] (4) After reacting for 4 hours, the container containing the reaction solution was placed in a mixture of ice and water and rapidly cooled to room temperature to quench the reaction and obtain a dark blue solution.

[0063] (5) Add 10 mL of ethanol to the above solution to precipitate the nanoparticles, and cesium tungstate nanoparticles with a particle size of 18±3 nm can be obtained after centrifugation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com