A kind of modified mineral fiber cotton and preparation method thereof

A mineral fiber and mineral wool technology, applied in the field of mineral fiber cotton, can solve the problems of poor dispersion of mineral fiber, poor affinity of rubber and resin, poor waterproof and heat insulation effects, etc., and achieve good fireproof and heat preservation effects. Strong hydrophobicity and low natural bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

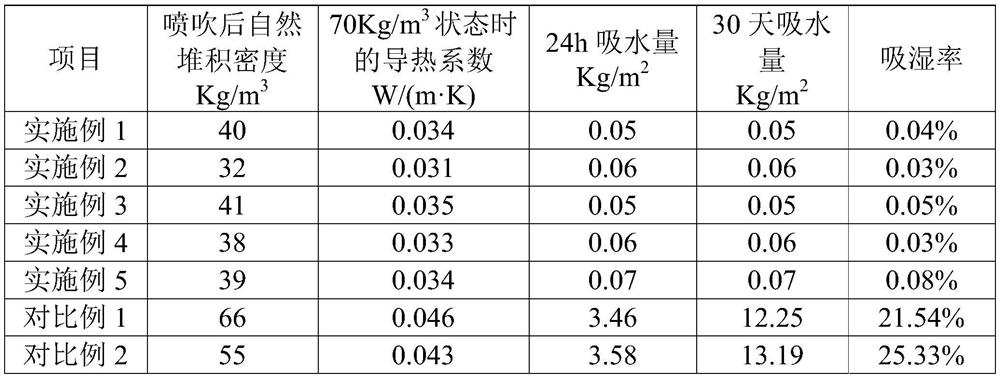

Examples

Embodiment 1

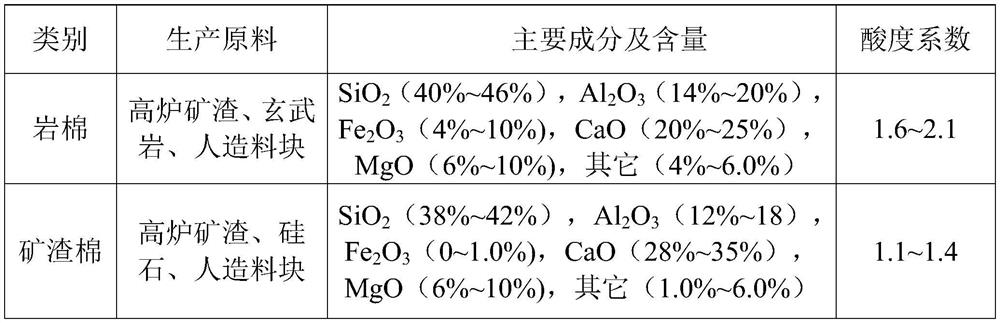

[0037] (1) After mixing the raw materials for producing rock wool (blast furnace slag, basalt, and artificial material blocks at a weight ratio of 1:5:2), melt them into high-temperature raw material slurry at 1500°C;

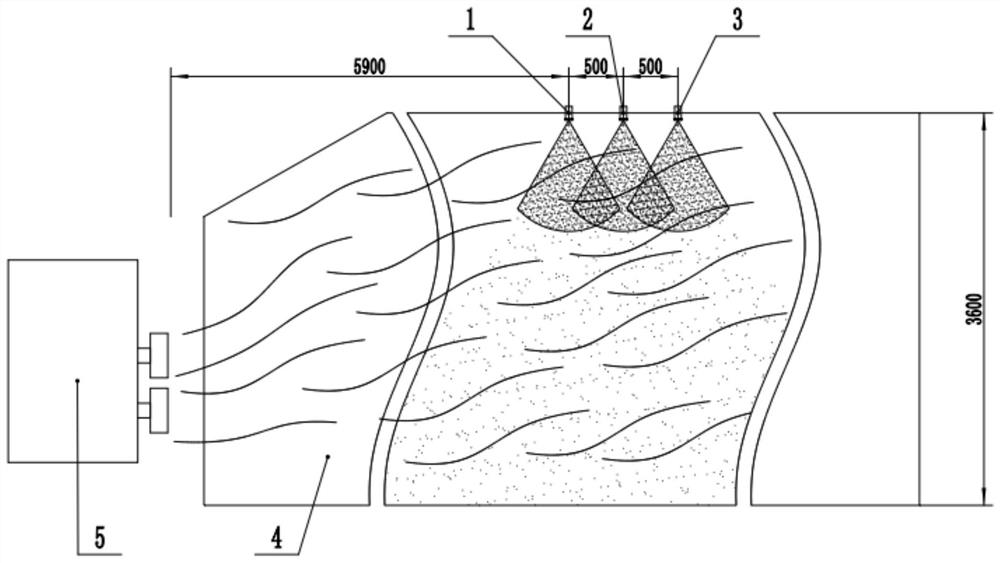

[0038] (2) Throw the high-temperature mixed slurry into a cotton collection box with 3 spray ports with a diameter of 2cm on the top under the conditions of a centrifuge speed of 7000r / min and a wind speed of 200m / s, and make minerals with an average diameter of 5um cotton;

[0039] (3) When the temperature of the mineral wool in the cotton collection box drops to 130°C, use a two-fluid atomizing nozzle at the 1# spray port on the top of the cotton collection box, and use compressed air with a working pressure of 0.6MPa to spray the silane coupling agent KH580 is atomized and evenly sprayed on the surface of mineral wool through the opening on the top of the cotton collection box. The amount of silane coupling agent KH580 accounts for 0.3% of the weight of mine...

Embodiment 2

[0043] (1) The raw materials for producing slag wool (blast furnace slag, silica, and artificial material blocks in a weight ratio of 5:1:2) are mixed and then melted at 1430°C to form a high-temperature raw material slurry;

[0044] (2) The high-temperature mixed slurry is thrown into a cotton collecting box with 3 holes with a diameter of 2cm on the top under the conditions of a centrifuge speed of 7200r / min and a wind speed of 220m / s, and an average diameter of 3.8um is produced. cotton;

[0045] (3) When the temperature of the mineral wool in the cotton collection box drops to 130°C, use a two-fluid atomizing nozzle at the 1# spray port on the top of the cotton collection box, and use compressed air with a working pressure of 0.6MPa to spray the silane coupling agent KH171 is atomized and evenly sprayed on the surface of the mineral wool through the opening on the top of the cotton collecting box. The silane coupling agent KH171 accounts for 0.5% of the weight of the miner...

Embodiment 3

[0049] (1) After mixing the raw materials for rock wool production (blast furnace slag, basalt, and artificial material blocks at a weight ratio of 1:5:2), melt them into high-temperature raw material slurry at 1450°C;

[0050] (2) The high-temperature mixed slurry is thrown into the cotton collection box with 3 spray ports with a diameter of 2cm at the top under the conditions of a centrifuge speed of 7300r / min and a wind speed of 220m / s, and an average diameter of 4.8um is made. mineral wool;

[0051] (3) When the temperature of the mineral wool in the cotton collection box drops to 130°C, use a two-fluid atomizing nozzle at the 1# spray port on the top of the cotton collection box, and use compressed air with a working pressure of 0.6MPa to spray the silane coupling agent JH-N308 is atomized and evenly sprayed on the surface of mineral wool through the opening on the top of the cotton collection box. The amount of silane coupling agent JH-N308 accounts for 0.3% of the weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com