Durable concrete and preparation method

A technology of durable concrete and sodium alginate, applied in the field of building materials, can solve the problems of easy generation of cracks, reduced use safety of concrete structures, poor durability, etc., and achieves the effects of improving strength, being beneficial to popularization and application, and preventing cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

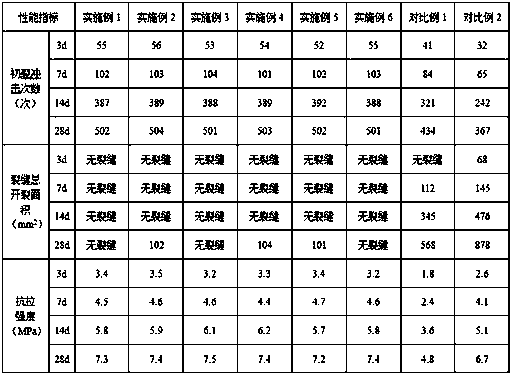

Examples

Embodiment 1

[0030] (1) Dissolve polypropylene and polyvinyl alcohol in dimethyl sulfoxide, add nano-silica and gallium trichloride to disperse to make a spinning solution, then perform electrospinning, and cut the obtained fibers into Short fibers, immersed in water to remove gallium trichloride, prepared polypropylene / polyvinyl alcohol composite porous fibers with nano-silica uniformly dispersed; the spinning voltage of electrospinning was 9V, the receiving distance was 16cm, and the diameter of the spinning hole was 300nm; the immersion time of fiber in water is 50min; in the spinning solution, 9 parts by weight of polypropylene, 7 parts by weight of polyvinyl alcohol, 2 parts by weight of nano silicon dioxide, 5 parts by weight of gallium trichloride, dimethyl Sulfone 77 parts by weight;

[0031] (2) Place the composite porous fiber prepared in step (1) in an aqueous solution of sodium alginate, perform ultrasonic treatment, then filter and dry to obtain a composite porous fiber adsorb...

Embodiment 2

[0034] (1) Dissolve polypropylene and polyvinyl alcohol in dimethyl sulfoxide, add nano-silica and gallium trichloride to disperse to make a spinning solution, then perform electrospinning, and cut the obtained fibers into Short fibers, immersed in water to remove gallium trichloride, prepared polypropylene / polyvinyl alcohol composite porous fibers with nano-silica uniformly dispersed; the spinning voltage of electrospinning was 8V, the receiving distance was 10cm, and the diameter of the spinning hole was 200nm; the immersion time of the fiber in water is 30min; in the spinning solution, 6 parts by weight of polypropylene, 5 parts by weight of polyvinyl alcohol, 1 part by weight of nano silicon dioxide, 4 parts by weight of gallium trichloride, dimethyl 84 parts by weight of sulfone;

[0035] (2) Place the composite porous fiber prepared in step (1) in an aqueous solution of sodium alginate, perform ultrasonic treatment, then filter and dry to obtain a composite porous fiber ...

Embodiment 3

[0038] (1) Dissolve polypropylene and polyvinyl alcohol in dimethyl sulfoxide, add nano-silica and gallium trichloride to disperse to make a spinning solution, then perform electrospinning, and cut the obtained fibers into Short fiber, immersed in water to remove gallium trichloride, prepared polypropylene / polyvinyl alcohol composite porous fiber with nano-silica uniformly dispersed; the spinning voltage of electrospinning was 12V, the receiving distance was 20cm, and the diameter of the spinning hole was 500nm; the immersion time of the fiber in water is 90min; in the spinning solution, 12 parts by weight of polypropylene, 8 parts by weight of polyvinyl alcohol, 3 parts by weight of nano-silicon dioxide, 8 parts by weight of gallium trichloride, dimethyl methylene Sulfone 69 parts by weight;

[0039] (2) Place the composite porous fiber prepared in step (1) in an aqueous solution of sodium alginate, perform ultrasonic treatment, then filter and dry to obtain a composite porou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com