A kind of ion-selective nano channel membrane and preparation method thereof

An ion-selective, nano-channel technology, applied in the field of energy, can solve problems such as failure to meet expectations and restrict application development, and achieve the effects of reducing transmembrane impedance, promoting ion diffusion and the generation of diffusion potential, and increasing open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

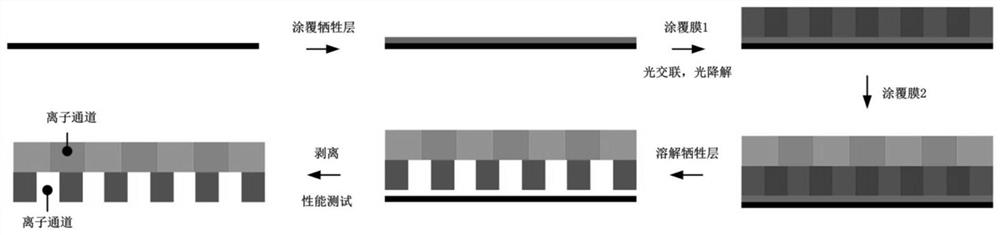

[0037] Such as figure 1 Shown, a kind of preparation method of ion-selective nanochannel membrane, described method comprises the steps:

[0038] 1) forming a sacrificial layer on a solid substrate to obtain a solid substrate coated with a sacrificial layer;

[0039] Suspension-coat sodium polystyrene sulfonate with a mass fraction of 5% on a silicon wafer at a rotational speed of 1600 r / s for 120 s.

[0040] 2) The block copolymer 1 is dissolved in the selective solvent 1, and a film is formed on a solid substrate coated with a sacrificial layer to form a block copolymer 1 film;

[0041] A poly(ethylene oxide-methacrylate) toluene solution with a mass fraction of 4% was suspended-coated on the silicon wafer coated with the sacrificial layer of sodium polystyrene sulfonate at a rotational speed of 1600 r / s for 60 s.

[0042] 3) heat treatment and light treatment of the block copolymer 1 film;

[0043] Vacuum treatment at a high temperature of 80 degrees Celsius for 4 hours...

Embodiment 2

[0052] Such as figure 1 Shown, a kind of preparation method of ion-selective nanochannel membrane, described method comprises the steps:

[0053] 1) forming a sacrificial layer on a solid substrate to obtain a solid substrate coated with a sacrificial layer;

[0054] Suspension-coat sodium polystyrene sulfonate with a mass fraction of 5% on a silicon wafer at a rotational speed of 1600 r / s for 120 s.

[0055] 2) The block copolymer 1 is dissolved in the selective solvent 1, and a film is formed on a solid substrate coated with a sacrificial layer to form a block copolymer 1 film;

[0056] A poly(ethylene oxide-methacrylate) toluene solution with a mass fraction of 4% was suspended-coated on the silicon wafer coated with the sacrificial layer of sodium polystyrene sulfonate at a rotational speed of 1600 r / s for 60 s.

[0057] 3) heat treatment and light treatment of the block copolymer 1 film;

[0058] Vacuum treatment at a high temperature of 80 degrees Celsius for 4 hours...

Embodiment 3

[0067] Such as figure 1 Shown, a kind of preparation method of ion-selective nanochannel membrane, described method comprises the steps:

[0068] 1) forming a sacrificial layer on a solid substrate to obtain a solid substrate coated with a sacrificial layer;

[0069] Suspension-coat sodium polystyrene sulfonate with a mass fraction of 5% on a silicon wafer at a rotational speed of 1600 r / s for 120 s.

[0070] 2) The block copolymer 1 is dissolved in the selective solvent 1, and a film is formed on a solid substrate coated with a sacrificial layer to form a block copolymer 1 film;

[0071] A poly(ethylene oxide-methacrylate) toluene solution with a mass fraction of 4% was suspended-coated on the silicon wafer coated with the sacrificial layer of sodium polystyrene sulfonate at a rotational speed of 1600 r / s for 60 s.

[0072] 3) heat treatment and light treatment of the block copolymer 1 film;

[0073] Vacuum treatment at a high temperature of 80 degrees Celsius for 4 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com