Chemical mechanical polishing solution for sapphires and preparation method of chemical mechanical polishing solution

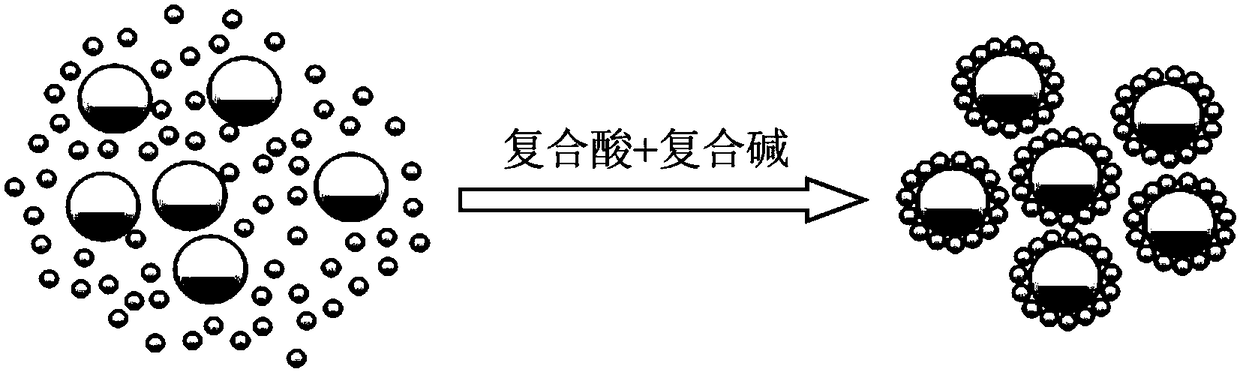

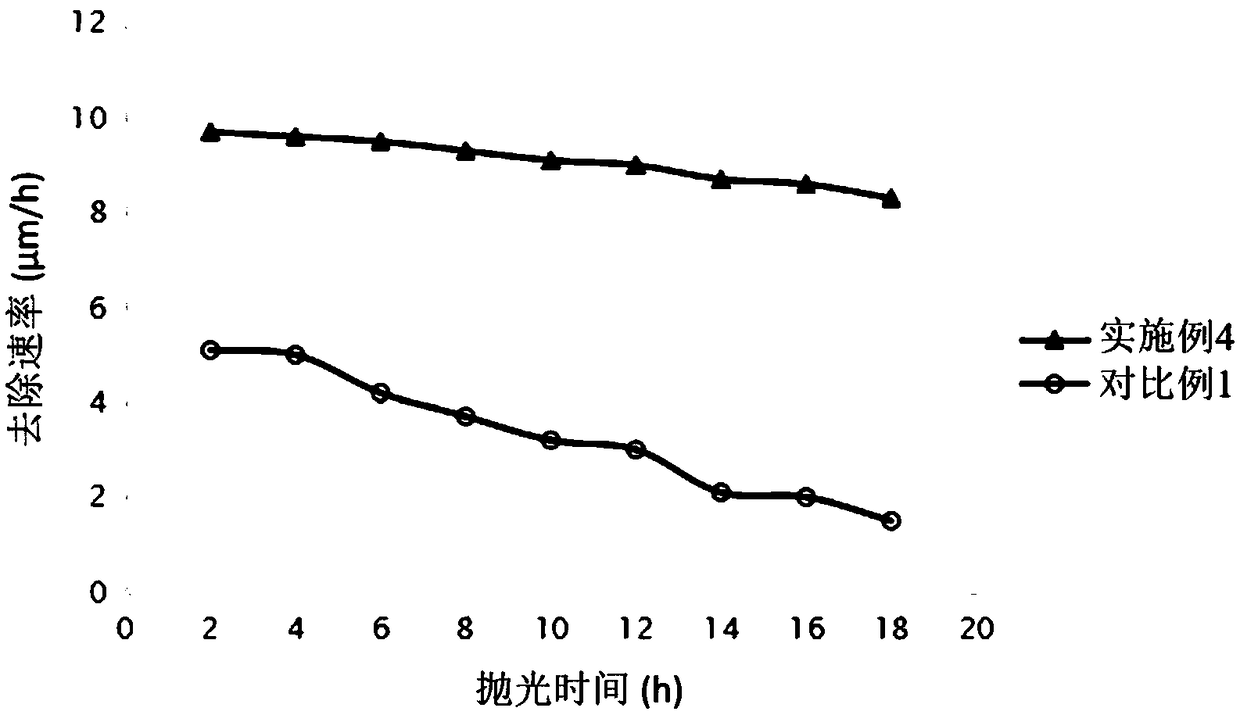

A technology of organic acid and inorganic acid, applied in the direction of polishing composition containing abrasives, etc., can solve the problems of low processing efficiency, short service life, slow polishing rate, etc., and achieve high polishing rate, improved surface quality and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

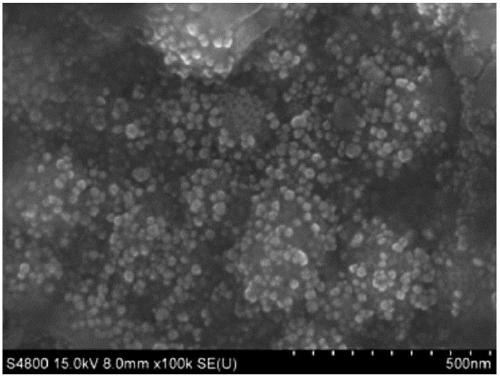

Method used

Image

Examples

Embodiment 1

[0027] 5kg mass fraction is 5% 80nm silica sol and 1kg mass fraction is 25% 25nm silica sol is poured in the reactor and stirs and mixes evenly, heats up to 50 ℃; The acid mass ratio is 1:1) to adjust the pH of the mixed silica sol in the reactor to 6.5, heat preservation and stirring for aging for 1 hour; use sodium hydroxide and monoethanolamine compound alkali (sodium hydroxide and monoethanolamine mass ratio is 1:1) The pH of the sol was 9.5, and then aged with heat preservation and stirring for 1 hour, and then cooled to room temperature; then, the sapphire chemical mechanical polishing solution of Example 1 was obtained by circulating and filtering for 1 hour with a filter element with an average pore diameter of 1 micron.

Embodiment 2

[0029] 5kg mass fraction is 20% 120nm silica sol and 1kg mass fraction is 20% 15nm silica sol pours in the reaction kettle and stirs and mixes evenly, heats up to 90 ℃; Ratio of 1:1) to adjust the pH of the mixed silica sol in the reactor to 7.5, heat preservation and stirring and aging for 1 hour; The pH of the sol was 10.5, and then aged with heat preservation and stirring for 1 hour, and then cooled to room temperature; the sapphire chemical mechanical polishing solution of Example 2 was obtained by circulating and filtering for 1 hour with a filter element with an average pore size of 1 micron.

Embodiment 3

[0031] 5kg mass fraction is that 40% 140nm silica sol and 15kg mass fraction are 5% 5nm silica sol are poured in the reaction kettle and stir and mix evenly, heat up to 110 ℃; 1:1) adjust the pH of the mixed silica sol in the reaction kettle to 8, keep warm and stir for aging for 1 hour; use ammonia water and tetramethylethylenediamine compound alkali (the mass ratio of ammonia water and tetramethylethylenediamine is 1:1) The pH of the sol was 11.5, and then aged with heat preservation and stirring for 1 hour, and then cooled down to room temperature; the sapphire chemical mechanical polishing solution of Example 3 was obtained by circulating and filtering for 1 hour with a filter element with an average pore diameter of 1 micron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com