Cyan silicate super-long afterglow luminescent material and preparation method thereof

A luminescent material and silicate technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of single afterglow color and short afterglow time, and achieve the effects of long afterglow time, high afterglow intensity and excellent afterglow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

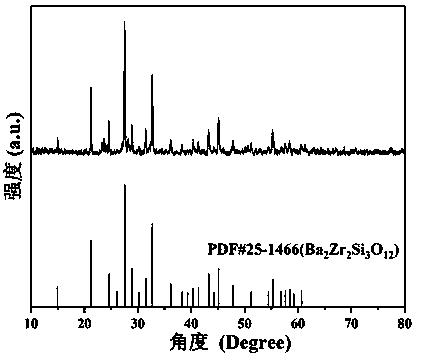

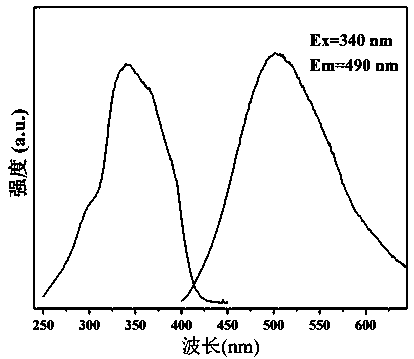

[0038] Press Ba 1.98 Zr 2 Si 3 O 12 :0.01Eu 2+ , 0.01Nd 3+ The stoichiometric ratio shown in the molecular formula, weigh 0.3907g BaCO 3 , 0.2464g ZrO 2 , 0.1803g SiO 2 , 0.0018g Eu 2 O 3 And 0.0017g Nd 2 O 3 As raw materials, the weighed raw materials are ground and mixed uniformly and then placed in an alumina crucible, and pre-fired in an air atmosphere. The pre-fired temperature is 1200°C, and the pre-fired time is 4 hours. The mixture is naturally cooled and ground and mixed evenly. In an environment of 1400°C, calcined for 6 hours in a reducing atmosphere. The reducing atmosphere is composed of 95% nitrogen and 5% hydrogen. The calcined powder is cooled to room temperature with the furnace to obtain the calcined product; after grinding, prepare Obtained cyan silicate ultra-long afterglow luminescent material. figure 1 Shown is the XRD pattern of the long afterglow luminescent material, indicating that the phase of the material is Ba 2 Zr 2 Si 3 O 12 . The excitation and e...

Embodiment 2

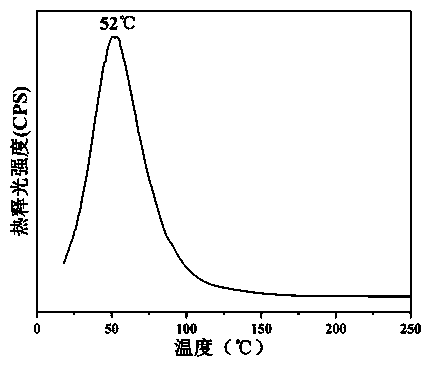

[0040] Press Ba 1.98 Zr 1.5 Hf 0.5 Si 3 O 12 :0.01Eu 2+ , 0.01Nd 3+ The stoichiometric ratio shown in the molecular formula, weigh 0.3907gBaCO 3 , 0.3157g HfO 2 , 0.0616g ZrO 2 , 0.1803g SiO 2 , 0.0018g Eu 2 O 3 And 0.0017g Nd 2 O 3 As raw materials, the weighed raw materials are ground and mixed uniformly and then placed in an alumina crucible, and pre-fired in an air atmosphere. The pre-fired temperature is 1200°C, and the pre-fired time is 4 hours. The mixture is naturally cooled and ground and mixed evenly. In an environment of 1400°C, calcined for 6 hours in a reducing atmosphere. The reducing atmosphere is composed of 95% nitrogen and 5% hydrogen. The calcined powder is cooled to room temperature with the furnace to obtain the calcined product; after grinding, prepare Obtained cyan silicate ultra-long afterglow luminescent material. Figure 5 0.0020g sample Ba 1.98 Hf 1.5 Zr 0.5 Si 3 O 12 :0.01Eu 2+ , 0.01Nd 3+ The pyro-release spectrum measured after 3 minutes of simultane...

Embodiment 3

[0042] Press Ba 1.98 Hf 2 Si 3 O 12 :0.01Eu 2+ , 0.01Nd 3+ The stoichiometric ratio shown in the molecular formula, weigh 0.3907g BaCO 3 , 0.4210g HfO 2 , 0.1803g SiO 2 , 0.0018g Eu 2 O 3 And 0.0017g Nd 2 O 3 As raw materials, the weighed raw materials are ground and mixed uniformly and then placed in an alumina crucible, and pre-fired in an air atmosphere. The pre-fired temperature is 1200°C, and the pre-fired time is 4 hours. The mixture is naturally cooled and ground and mixed evenly. In an environment of 1400°C, calcined for 6 hours in a reducing atmosphere. The reducing atmosphere is composed of 95% nitrogen and 5% hydrogen. The calcined powder is cooled to room temperature with the furnace to obtain the calcined product; after grinding, prepare Obtained cyan silicate ultra-long afterglow luminescent material. Image 6 0.0020g sample Ba 1.98 Hf 2 Si 3 O 12 :0.01Eu 2+ , 0.01Nd 3+ The pyro-release spectra measured after 3 minutes of simultaneous irradiation of light sources wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com