A kind of carbon sphere/polyacrylonitrile fiber material and its preparation method and application

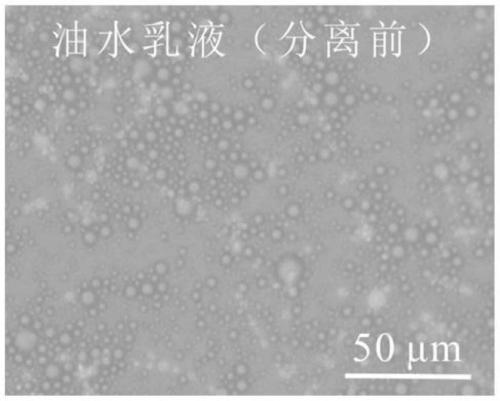

A technology of polyacrylonitrile fiber and polyacrylonitrile, which is applied in the field of carbon sphere/polyacrylonitrile fiber material and its preparation and application, which can solve the problems of poor structural effect, limited number of nodes, difficult formation, etc., and achieve good oil-water separation effect , significant structural effects and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] On the other hand, in some embodiments of this specification, a kind of preparation method of above-mentioned carbon sphere / polyacrylonitrile fiber material is provided, and this method comprises the following steps:

[0045] Prepare the spinning stock solution, polyacrylonitrile is dissolved in the spinning stock solution, and carbon spheres with a particle diameter of 50nm-5 μm are dispersed; the mass ratio of carbon spheres and polyacrylonitrile in the spinning stock solution is (0.1-5): 10;

[0046] The carbon sphere / polyacrylonitrile fiber material is prepared by using the spinning stock solution as a raw material through an electrostatic spinning method.

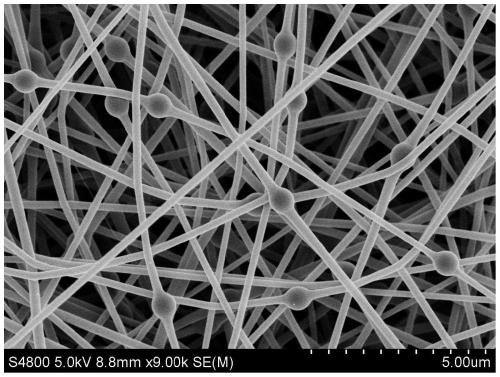

[0047] In this embodiment, when the particle size of carbon spheres is determined and the mass ratio of carbon spheres to polyacrylonitrile in the spinning dope is constant, a typical "spindle structure" (beaded structure) can be formed.

[0048] In this embodiment, the basic conditions and methods for preparin...

experiment example 1

[0066] In this experimental example, a carbon sphere / polyacrylonitrile porous fiber membrane was specifically prepared, and the preparation process was as follows:

[0067] (1) Preparation of monodisperse nano-carbon spheres: the molar ratio of ammonia, resorcinol, formaldehyde, ethanol, and water is (1-3): (1.4-2.8): (2.8-5.6): (0- 1186): (2311-0). First add absolute ethanol and ammonia water to deionized water and react in a water bath at 30°C for 1 hour; then add resorcinol and react in a water bath at 30°C for 0.5 hours; then add formaldehyde and react in a water bath at 30°C for 12 hours; After that, it was transferred to the reaction kettle, and hydrothermally reacted at 100°C for 24 hours; then it was centrifuged and purified with absolute ethanol and deionized water, and then dried at 80°C for 12 hours; then put into a tube furnace, under nitrogen environment The temperature is raised to 350°C for 2 hours, and then the temperature is raised to 600°C for 4 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com