Dielectric function gradient insulating dual-mode non-destructive testing method

A functional gradient and non-destructive testing technology, which is applied in computing models, character and pattern recognition, image data processing, etc., can solve problems such as differences in dielectric parameter recognition, difficult operation, difficult equivalence, etc., to solve nonlinear and pathological problems problem, solve highly nonlinear, and improve the effect of inversion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

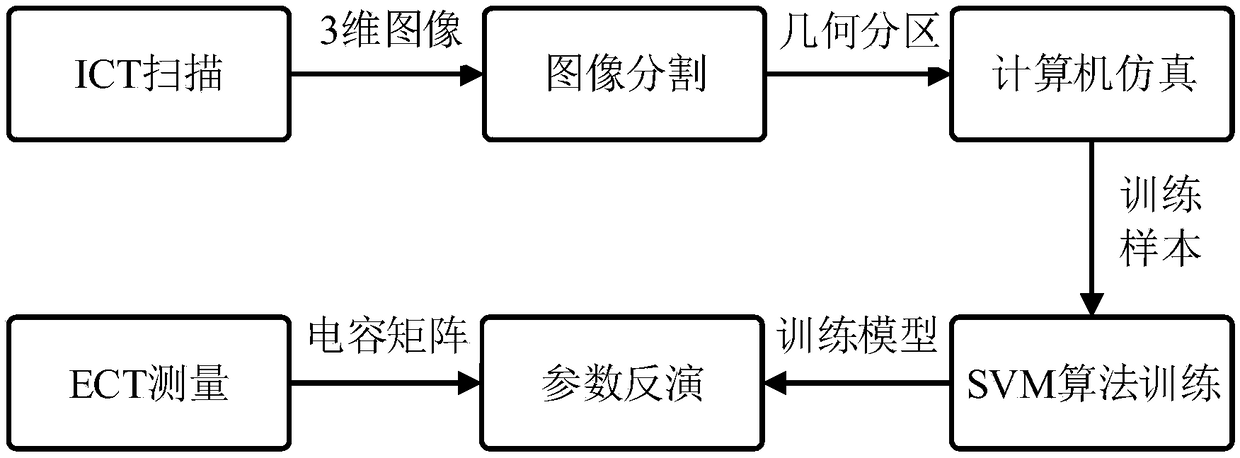

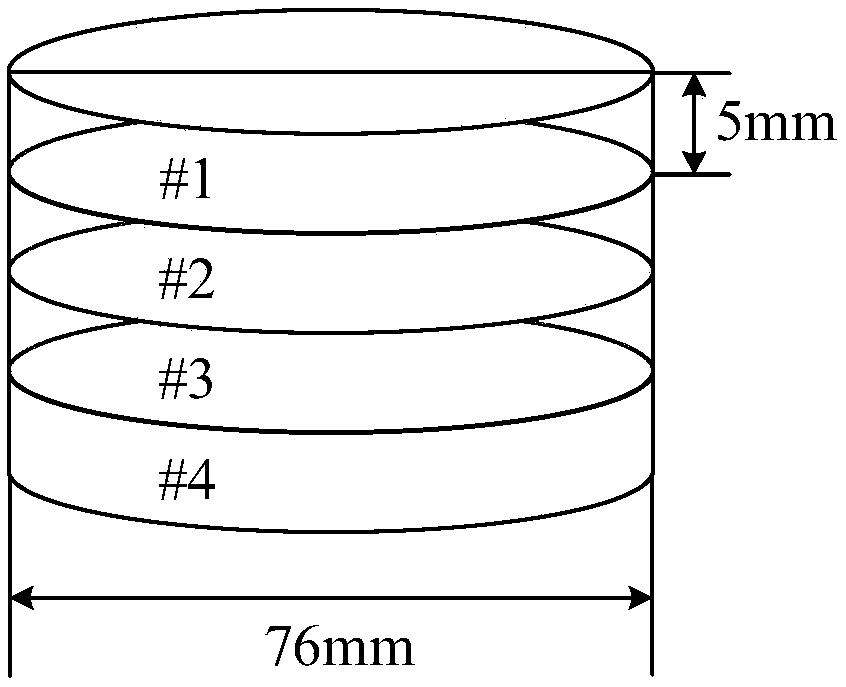

[0063] see figure 2 , for the designed dielectrically graded insulator. The insulator is cylindrical, and its specific dimensions are as follows: figure 2 As shown, it is divided into 4 layers, and the relative permittivity of the insulator is distributed in a gradient according to the layer. The detection process includes the following steps:

[0064] Step 1 analyzes the insulator to obtain the 3D grayscale information of the insulator;

[0065] Using the gray-scale multi-threshold segmentation algorithm in step 2, the insulator can be divided into four layers, as shown in Table 1, and the shape distinction inside the material can be realized by dividing the gray value range.

[0066] Table 1 Grayscale multi-threshold segmentation results

[0067] layer number

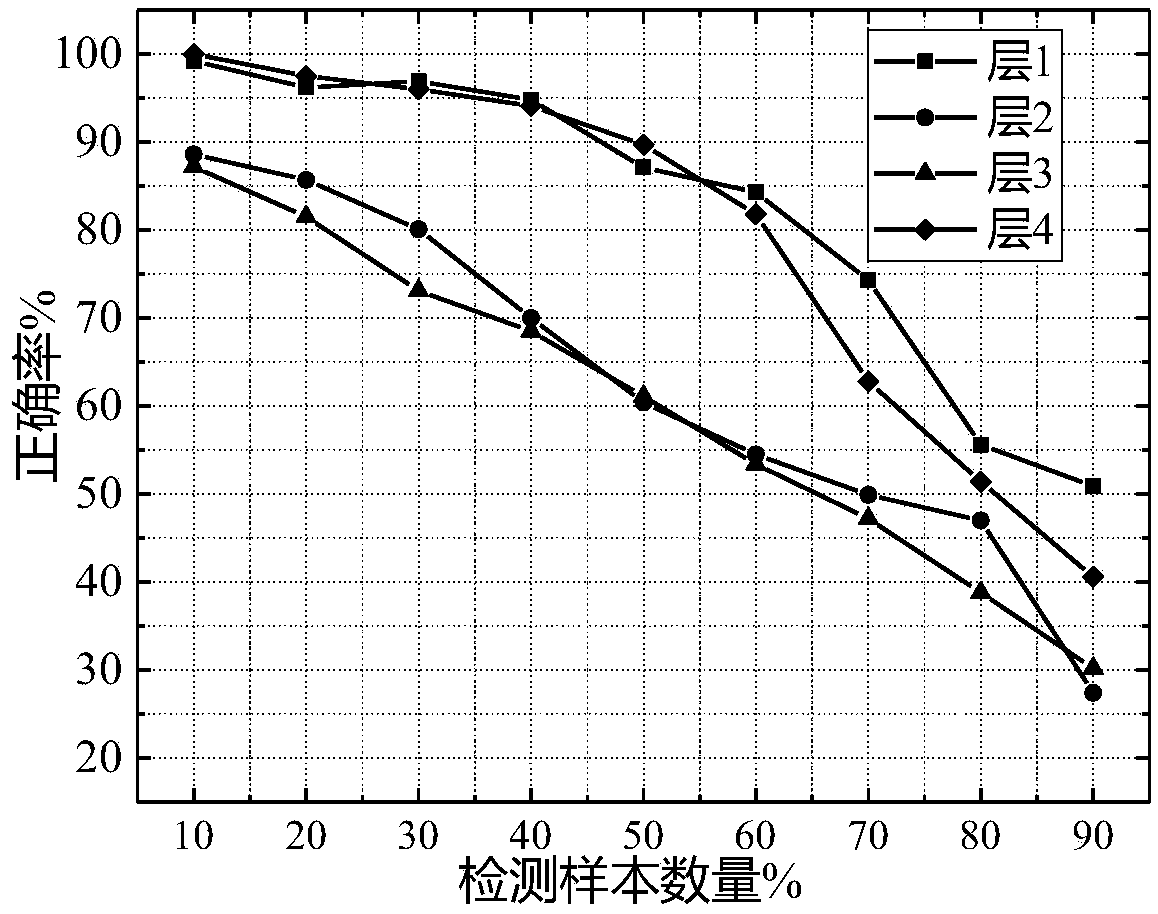

[0068] Step 3. Input the obtained 4-layer geometric information into the finite element simulation software, and set the material and its corresponding dielectric parameters and other information for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com