Formation method of IGBT device, and structure of IGBT device

A device structure and device technology, applied in the field of IGBT device formation and its structure, can solve problems such as increased capacitance, achieve the effects of improving conduction voltage drop, increasing process window, and improving capacitance Cgc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] As mentioned in the background art, in trench type IGBT devices, a redundant cell (dummy cell) is formed between multiple functional cells to reduce the channel density, thereby improving the short-circuit resistance of the IGBT device. question. However, this method will correspondingly cause the capacitance Cgc between the gate and the collector to increase, thereby affecting the overall performance of the device.

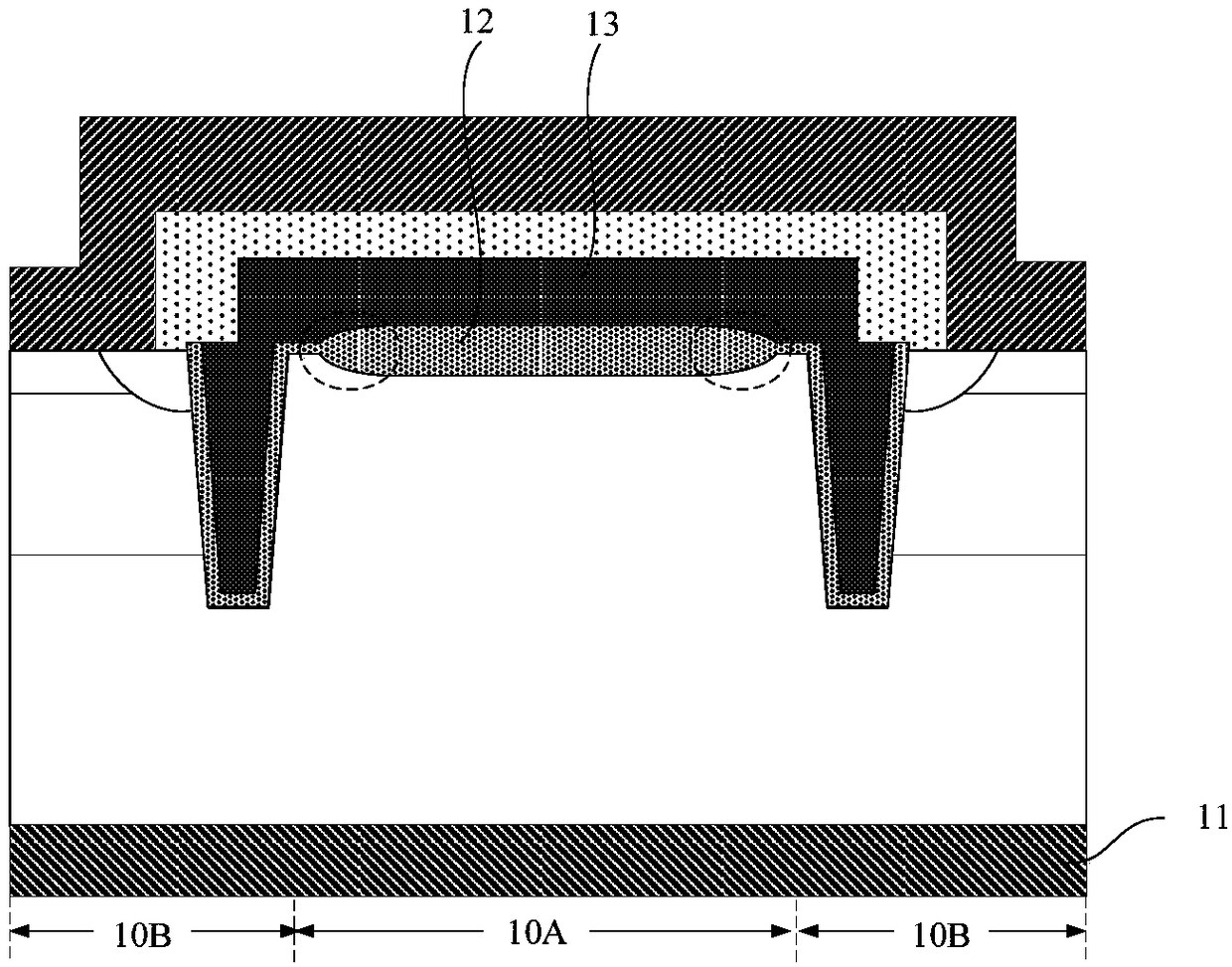

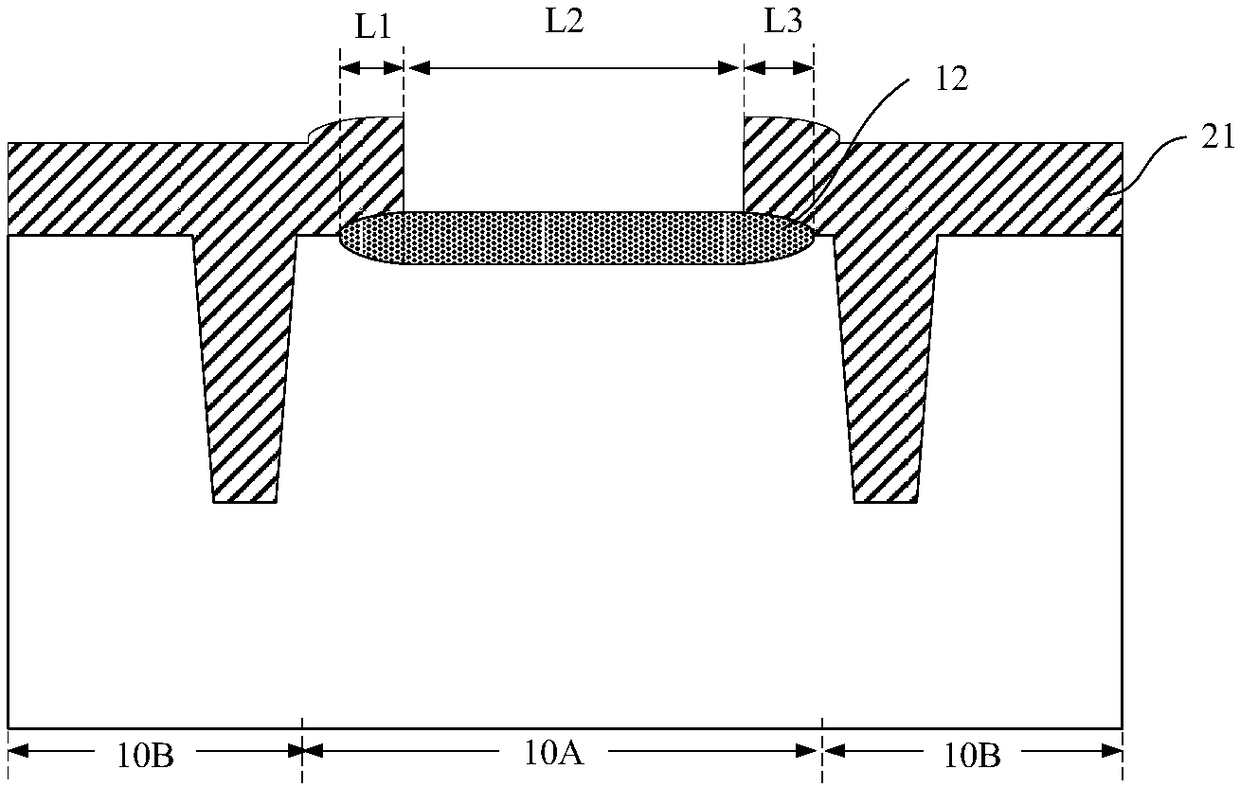

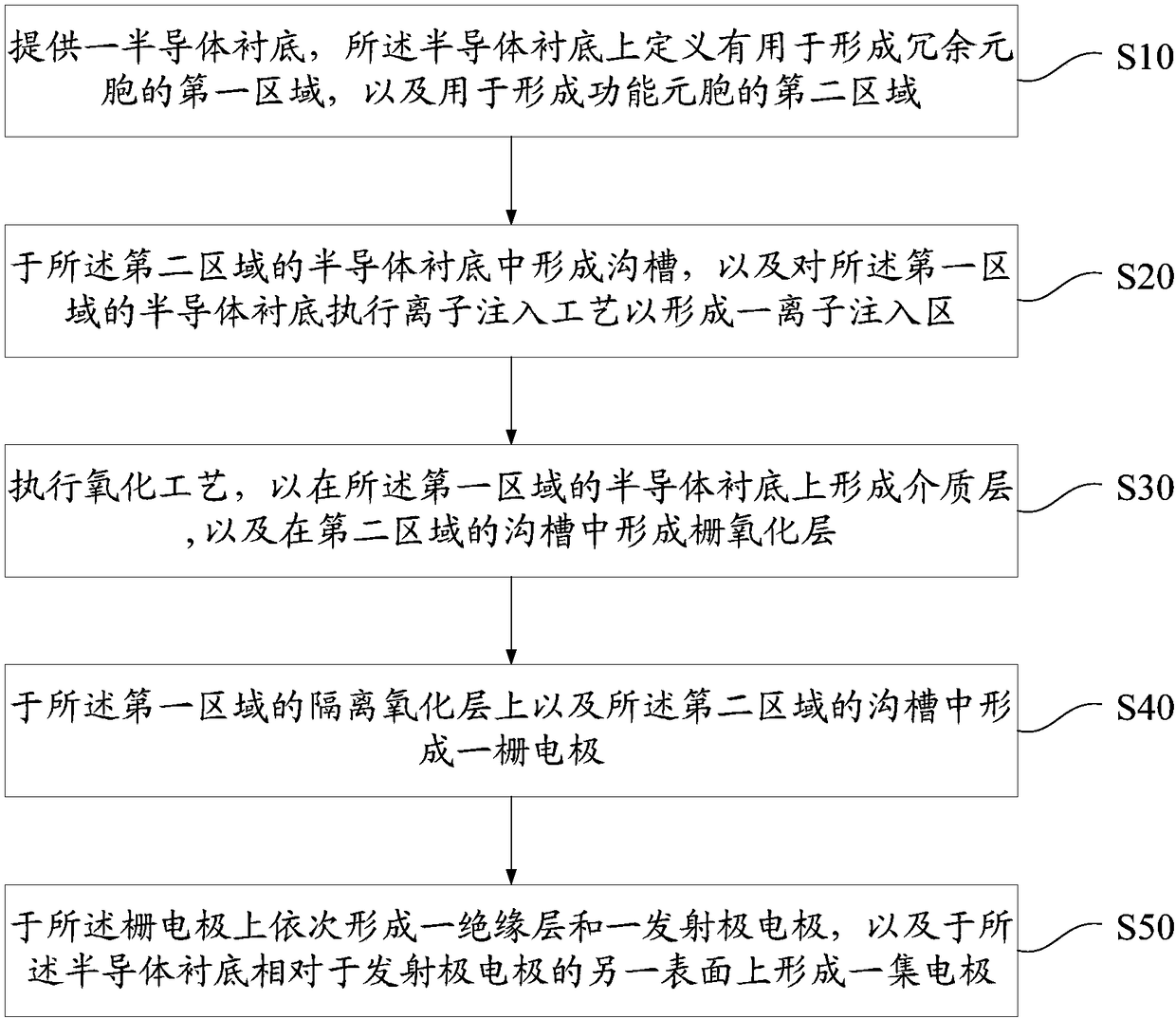

[0037] In order to improve the capacitance Cgc between the gate and the collector, it is usually necessary to form a thicker dielectric layer between the gate electrode and the collector in the redundant cell. figure 1 is a schematic structural diagram of an IGBT device, such as figure 1 As shown, the IGBT device has a plurality of functional cells 10B and a redundant cell 10A between the plurality of functional cells 10B, and the redundant cell 10A includes a collector 11, a dielectric layer 12 and a Gate electrode 13. Wherein, the dielectric layer 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Feature size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com