Composite reinforced solder and preparation method thereof

A composite solder technology, applied in the direction of welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of strengthening solder yield strength, unsatisfactory creep resistance, etc., to improve creep resistance and anti-corrosion Effects of fatigue performance, increased dislocation density, and improved yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

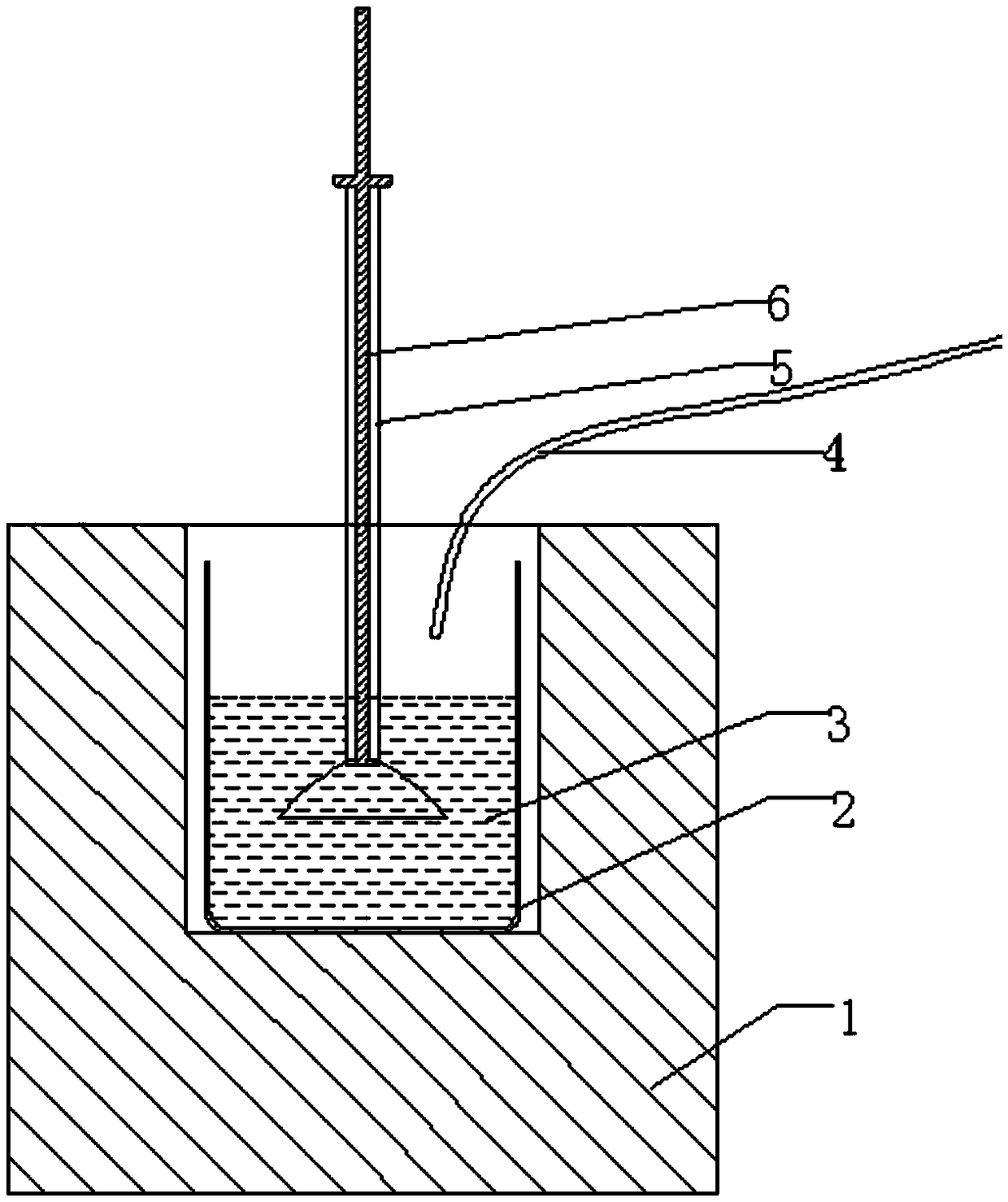

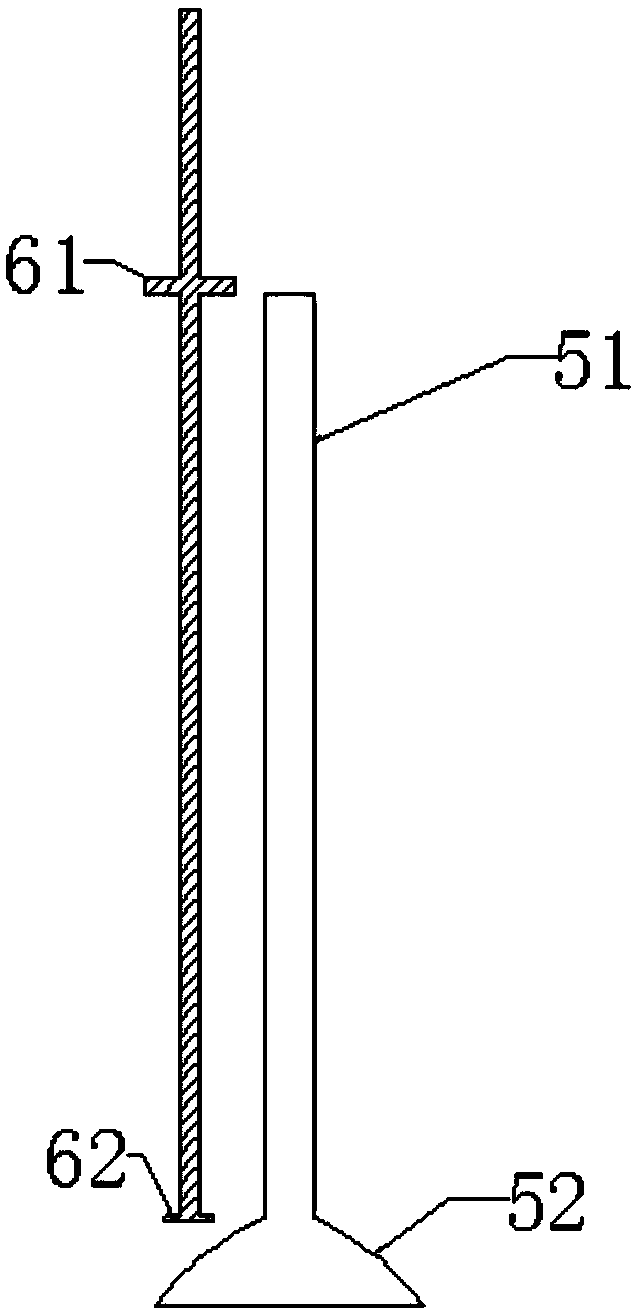

Method used

Image

Examples

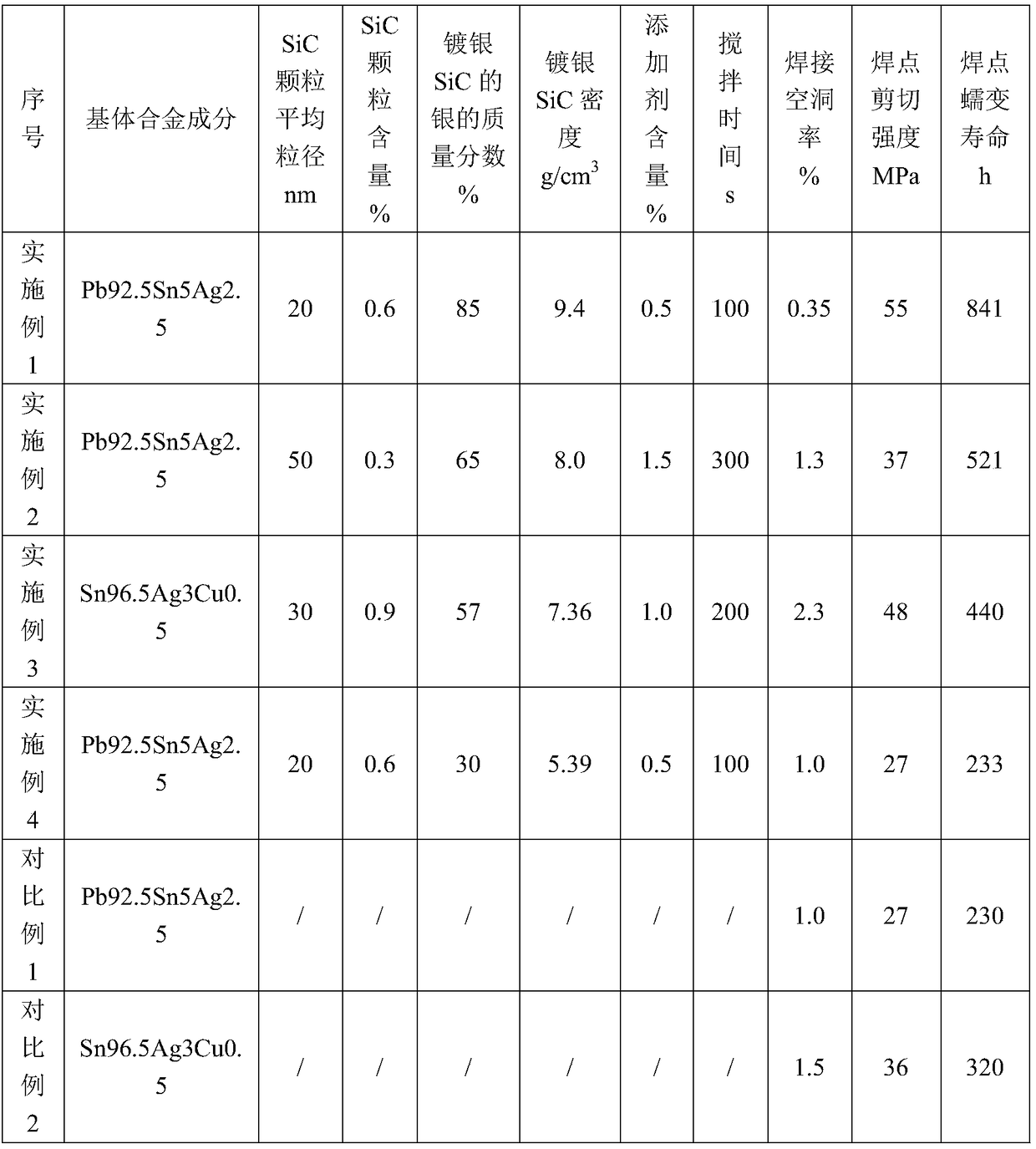

Embodiment 1

[0057] Choose SiC powder with an average particle size of 20nm, the mass fraction of silver in silver-coated SiC is 85%, and the density is approximately equal to 9.4g / cm 3 , the amount of SiC particles added accounts for about 0.6% of the weight of the base alloy, that is, the weight of the silver-plated SiC is 60g, and the amount of organic additives is 0.5% of the weight of the silver-plated SiC, that is, 0.3g. Silver-coated SiC particles, organic additives, and 12 ml of analytical ethanol were mixed into a slurry, and then the SiC slurry was added to 1500 g of Pb92.5Sn5Ag2.5 molten solder matrix alloy (alloy density 11.1 g / cm 3 ), the stirring time is 100s.

Embodiment 2

[0059] Choose SiC powder with an average particle size of 50nm, the mass fraction of silver in silver-coated SiC is 65%, and the density is approximately equal to 8.0g / cm 3 The amount of SiC particles added accounts for about 0.3% of the weight of the base alloy, that is, the weight of the silver-plated SiC is 12.8g, and the amount of organic additives is 1.5% of the weight of the silver-plated SiC, that is, 0.2g. Silver-plated SiC particles, organic additives and 3ml of analytical ethanol were mixed into a slurry, and then the SiC slurry was added to 1500g of Pb92.5Sn5Ag2.5 molten solder matrix alloy according to the above embodiment, and the stirring time was 300s.

Embodiment 3

[0061] Choose SiC powder with an average particle size of 30nm, the mass fraction of silver in silver-coated SiC is 57%, and the density is approximately equal to 7.36g / cm 3 , the amount of SiC particles added accounts for about 0.9% of the weight of the base alloy, that is, the weight of the silver-plated SiC is 31.4g, and the amount of organic additives is 1.0% of the weight of the silver-plated SiC, that is, 0.31g. Silver-coated SiC particles, organic additives, and 7 ml of analytical ethanol were mixed into a slurry, and then the SiC slurry was added to 1500 g of Sn96.5Ag3Cu0.5 molten solder matrix alloy (alloy density of 7.37 g / cm 3 ), the stirring time was 200s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com