Electromagnetic wave transmission compound material as well as preparation method and application thereof

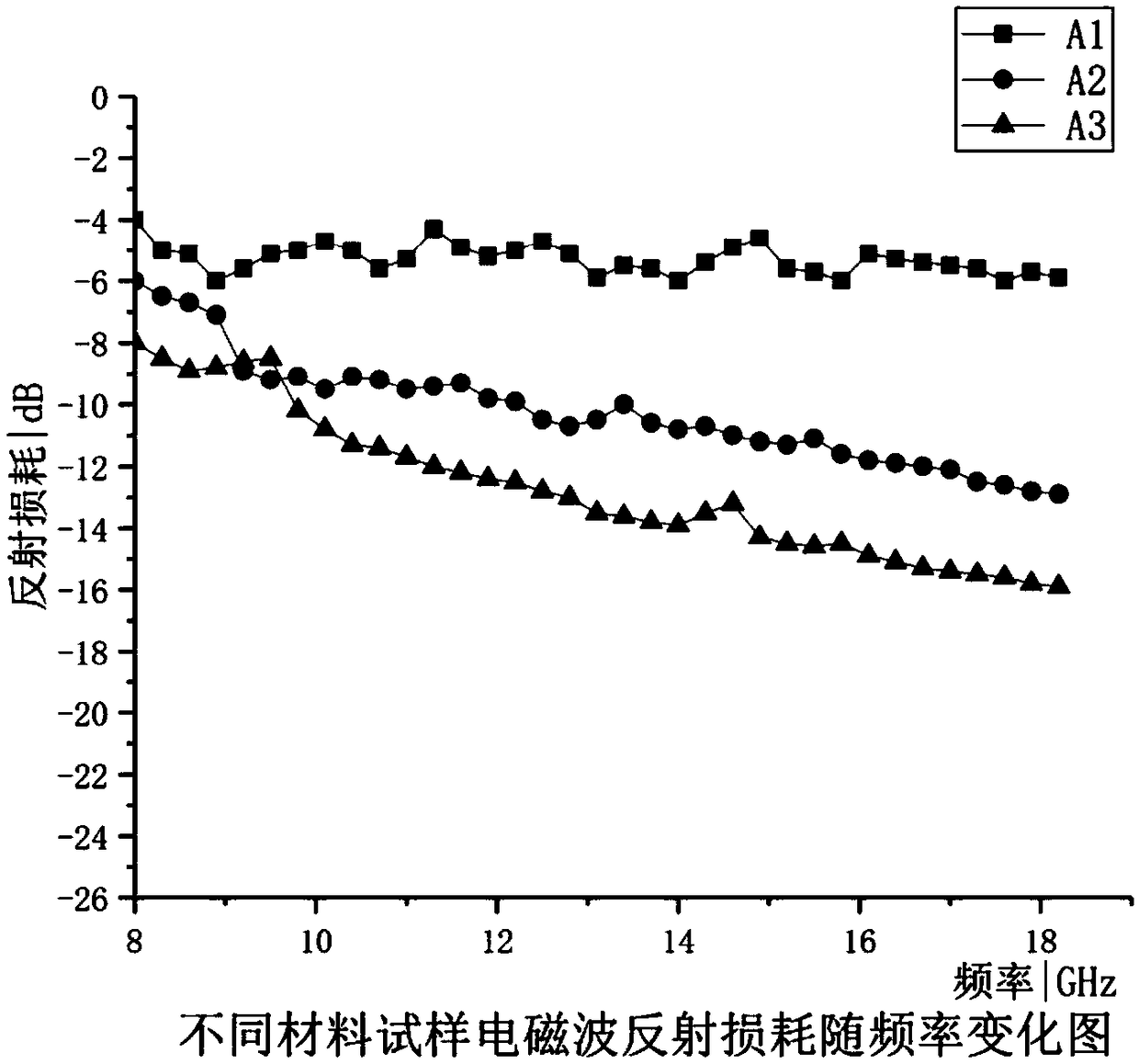

A composite material, electromagnetic wave technology, applied in the field of composite materials, can solve the problems of low compressive strength, inability to guarantee internal porosity, easy collapse mode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] An embodiment of the present invention provides an electromagnetic wave transmission composite material, the preparation method of which includes the following steps:

[0040] (1) prepare alkali activator: water, water glass and sodium hydroxide are mixed, stir, then leave standstill 24h, obtain alkali activator; By mass ratio, water: water glass: sodium hydroxide=(45~55 ):1:2;

[0041] (2) Preparation of the first alkali-activated slag cementitious material: add fly ash and slag to a slurry mixer, stir evenly to obtain a mixed ash body, then add an alkali activator, and stir evenly to obtain the first alkali-activated slag Cementitious material; by mass ratio, fly ash: slag = (7:5) ~ (10:3), mixed ash body: alkali activator = 1: (0.4 ~ 0.5);

[0042] (3) Sodium bicarbonate is added in the epoxy resin glue, stir evenly, obtain mixture A; According to mass volume ratio, sodium bicarbonate: epoxy resin glue=2~3g:20~30mL;

[0043] (4) Wash the expanded polystyrene partic...

Embodiment 1

[0050] Embodiment 1 provides an electromagnetic wave transmission composite material, the preparation method of which includes the following steps:

[0051] (1) prepare alkali activator: mix water, water glass and sodium hydroxide, stir 8~10min, then leave standstill 24h, obtain alkali activator; By mass ratio, water: water glass: sodium hydroxide=50: 1:2;

[0052] (2) Preparation of the first alkali-activated slag cementitious material: add fly ash and slag to a slurry mixer, stir for 120-150 seconds to obtain a mixed ash body, then add an alkali activator, and stir for 4-5 minutes to obtain the first A kind of alkali-activated slag cementitious material; By mass ratio, fly ash: slag=7:3, mixed ash body: alkali activator=1:0.4;

[0053] (3) Sodium bicarbonate is added in the epoxy resin glue, stirs 3~5min, obtains mixture A; According to mass volume ratio, sodium bicarbonate:epoxy resin glue=1g:10mL;

[0054] (4) Wash the expanded polystyrene particles with deionized water fo...

Embodiment 2

[0061] Embodiment 2 provides an electromagnetic wave transmission composite material, the preparation method of which includes the following steps:

[0062] (1) prepare alkali activator: mix water, water glass and sodium hydroxide, stir 8~10min, then leave standstill 24h, obtain alkali activator; By mass ratio, water: water glass: sodium hydroxide=45: 1:2;

[0063] (2) Preparation of the first alkali-activated slag cementitious material: add fly ash and slag to a slurry mixer, stir for 120-150 seconds to obtain a mixed ash body, then add an alkali activator, and stir for 4-5 minutes to obtain the first A kind of alkali-activated slag cementitious material; By mass ratio, fly ash: slag=7:5, mixed ash body: alkali activator=1:0.45;

[0064] (3) Sodium bicarbonate is added in the epoxy resin glue, stirs 3~5min, obtains mixture A; According to mass volume ratio, sodium bicarbonate:epoxy resin glue=2g:30mL;

[0065] (4) Wash the expanded polystyrene particles with deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com