A kind of solvent-free anticorrosion antistatic conductive coating and preparation method thereof

An anti-corrosion and solvent-free technology, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of easy gel deterioration, poor aging resistance, high dielectric constant, and improve light aging resistance. The effect of stable electrostatic protection performance and high electromagnetic wave transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

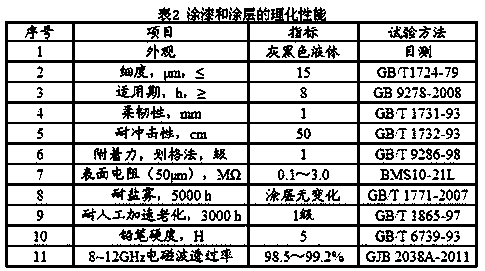

[0021] The solvent-free anti-corrosion and static-conductive paint with high electromagnetic wave transmittance proposed by the present invention has two components, the A component is the anti-corrosion and static-conductive paint, and the B component is a curing agent. The weight ratio of component A and component B is: component A:component B=100:60-70. Wherein, component A is prepared from the following raw materials in weight fraction ratio:

[0022] Polyurethane graft modified epoxy resin 60~70,

[0023] Semiconductor coated sheet mica powder 16~22,

[0024] Hydrochloric acid doped conductive polyaniline 10-16,

[0025] Wetting and dispersing agent 2~4,

[0026] Component B is γ-aminopropyltriethoxysilane, which is used as a curing agent.

[0027] Among them, the commercial brand of polyurethane grafted modified epoxy resin is SL102C-3, the viscosity is 1000-2000CP, and the epoxy value is 0.46; the mica powder particle size of the semiconductor coating sheet is 0.3-0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com