Cardanol-modified poly(ethylene 2,6-naphthalate) (PEN) and preparation method thereof

A technology of ethylene naphthalate and dimethyl naphthalate, which is applied in the field of cardanol-modified polyethylene-2,6-naphthalene dicarboxylate and its preparation, can solve the problem of 2,6- Higher purity requirements for naphthalene dicarboxylic acid, inability to obtain high-molecular-weight PEN polyester, low average product price and low profit margin, etc., to achieve the effects of avoiding fluctuations in the reaction system, shortening production time, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

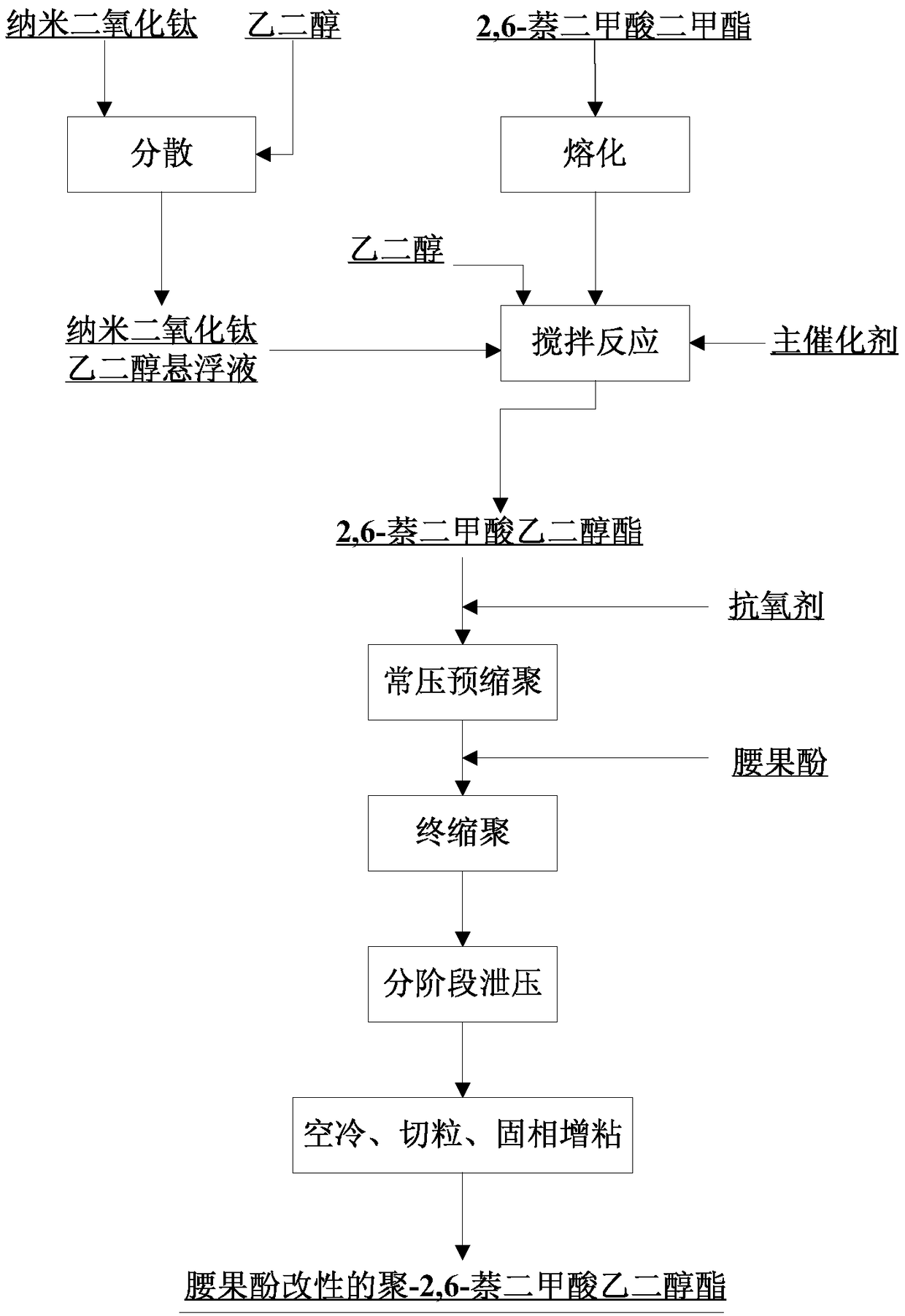

[0042] Specific embodiment one: A cardanol-modified polyethylene-2,6-naphthalene dicarboxylate resin of the present embodiment is prepared by dimethyl 2,6-naphthalene dicarboxylate, ethylene glycol, and cardanol through ester It is prepared by exchange reaction and condensation polymerization; the molar ratio of dimethyl 2,6-naphthalene dicarboxylate to ethylene glycol is 1: (1.9-2.5); the amount of cardanol is 2,6-naphthalenedi 1%-10% of the mass of dimethyl formate; the total amount of catalyst used is 4×10 -4 mol / mol-8×10 -4 mol / mol 2,6-dimethyl naphthalene dicarboxylate, wherein the molar ratio of main catalyst anhydrous zinc acetate and auxiliary catalyst nano-titanium dioxide is (5-10):1. The steps included in the preparation method of the present embodiment are as follows: figure 1 Shown: A certain proportion of dimethyl 2,6-naphthalene dicarboxylate and ethylene glycol undergo transesterification under the action of a catalyst. After a certain period of normal pressu...

specific Embodiment approach 2

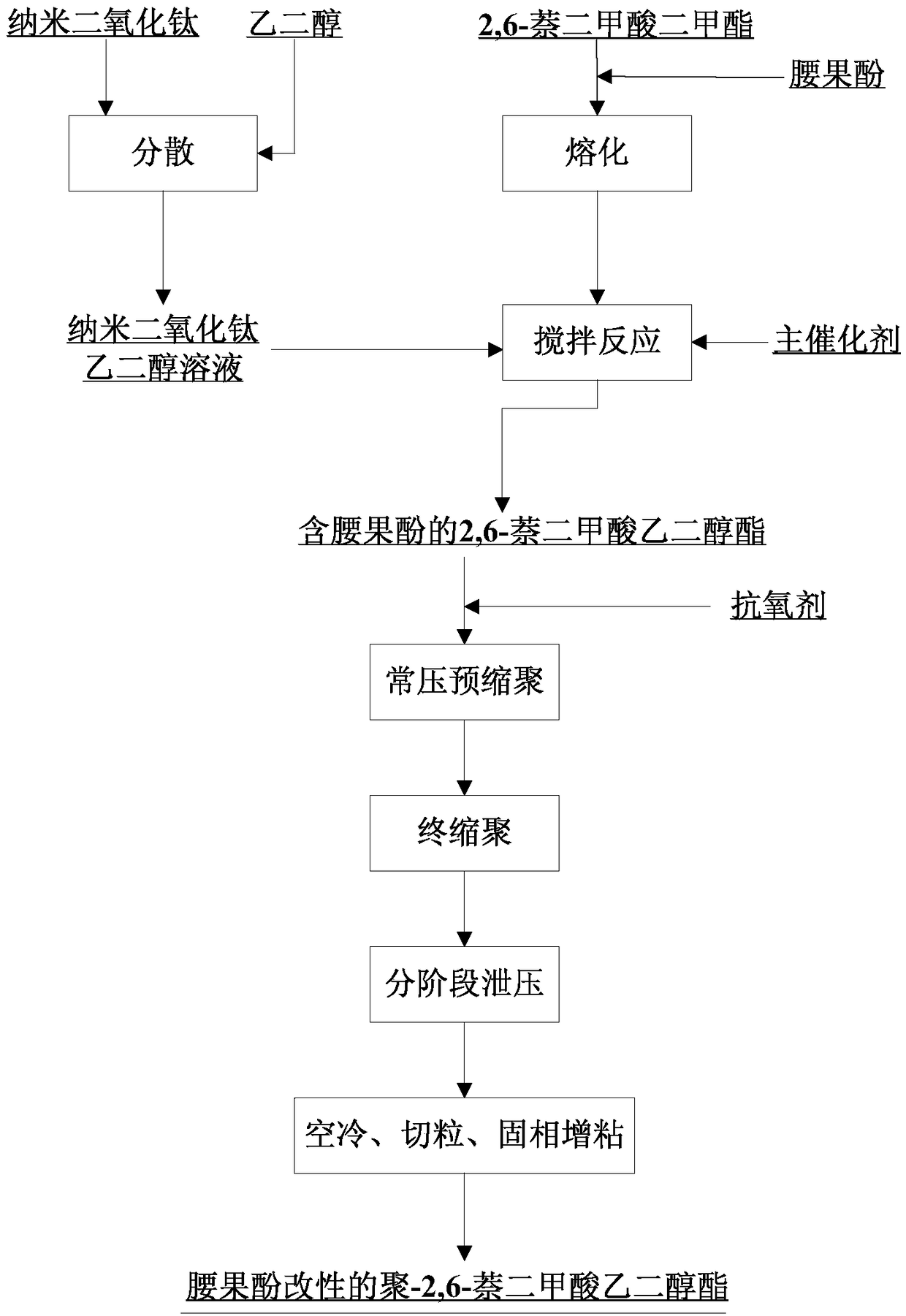

[0045] Specific implementation mode two: as figure 2 As shown, the difference between this embodiment and the first embodiment is that ethylene glycol is added to the reaction system after the transesterification reaction between dimethyl 2,6-naphthalene dicarboxylate and cardanol. Others are the same as the specific embodiment one, the chemical reaction equation of the present embodiment is:

[0046]

[0047] The present invention will be described in further detail below in conjunction with specific examples, and these examples should not be construed as limiting the scope of protection claimed by the present invention.

Embodiment 1

[0049] A preparation method of cardanol-modified polyethylene-2,6-naphthalene dicarboxylate, comprising the following steps:

[0050] (1) Preparation of Nano Titanium Dioxide Ethylene Glycol Suspension

[0051] Fully disperse 0.0106g nano-titanium dioxide in 2.12mL ethylene glycol to obtain nano-titanium dioxide ethylene glycol suspension, set aside;

[0052] (2) Preparation of 2,6-ethylene glycol naphthalate

[0053] Add 244 grams of dimethyl 2,6-naphthalene dicarboxylate into the reaction vessel, blow in nitrogen, heat the temperature to 165°C, wait until it is completely melted, add nano-titanium dioxide ethylene glycol suspension with 0.0106 g of nano-titanium dioxide dispersed by ultrasonic , after adding 109 ml of ethylene glycol, and then adding 0.1222 g of anhydrous zinc acetate, the temperature of the reaction vessel was raised to 195°C, and after transesterification for 3 hours, ethylene glycol 2,6-naphthalene dicarboxylate was obtained;

[0054] (3) polycondensati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com