Super durable ultraviolet ray curing coating

A UV and ultra-wear-resistant technology, applied in coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve problems such as insufficient scratch resistance, achieve strong cleaning power, and realize steel wool resistance Scratch, good effect of softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In the ultra-wear-resistant UV-cured coating according to the present invention, the preparation method of the phenyl silicone grafted hexafunctional polyurethane acrylate includes the steps: (1) at a temperature of 110-120°C and a vacuum of 0.06-0.1MPa Under conditions, after heating and drying dipentaerythritol for 3-4 hours, cool to 50-60° C. to obtain pretreated dipentaerythritol; (2) in molar parts, 100 parts of pretreated dipentaerythritol Put it into the reaction container together with 1-3 parts of the catalyst, after stirring evenly, add 600 parts of isophorone diisocyanate in batches, keep stirring, and react at a temperature of 70-80°C for 3-4 hours , to obtain a pre-reaction base liquid; (3) in parts by mole, add 10-20 parts of phenyltrichlorosiloxane at room temperature to the pre-reaction base liquid described in step (2) while keeping stirring, Stir for 10-20 minutes to obtain a pre-grafting reaction base liquid; (4) In the case of maintaining the tempera...

Embodiment 1

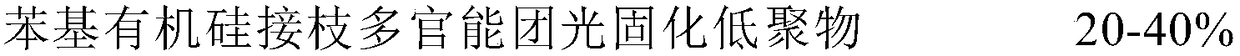

[0043] Super wear-resistant UV-cured coating, composed of the following raw materials in mass percentage:

[0044]

[0045]

[0046] Among them, nano-silica is activated by silane coupling agent KH550;

[0047] Preparation of phenyl silicone grafted hexafunctional polyurethane acrylate:

[0048] (1) Heat and dry dipentaerythritol for 3 hours at a temperature of 110°C and a vacuum of 0.06MPa, then cool to 50°C to obtain pretreated dipentaerythritol;

[0049] (2) In molar parts, 100 parts of pretreated dipentaerythritol and 1 part of dibutyltin laurate described in step (1) are put into the reaction vessel together, after stirring evenly, add 600 parts of molar parts in batches Isophorone diisocyanate, stirring continuously, reacted at a temperature of 70-80°C for 3 hours to obtain a pre-reaction base liquid;

[0050] (3) In parts by mole, add 10 parts of phenyltrichlorosiloxane at room temperature to the pre-reaction base liquid described in step (2) while stirring, and...

Embodiment 2

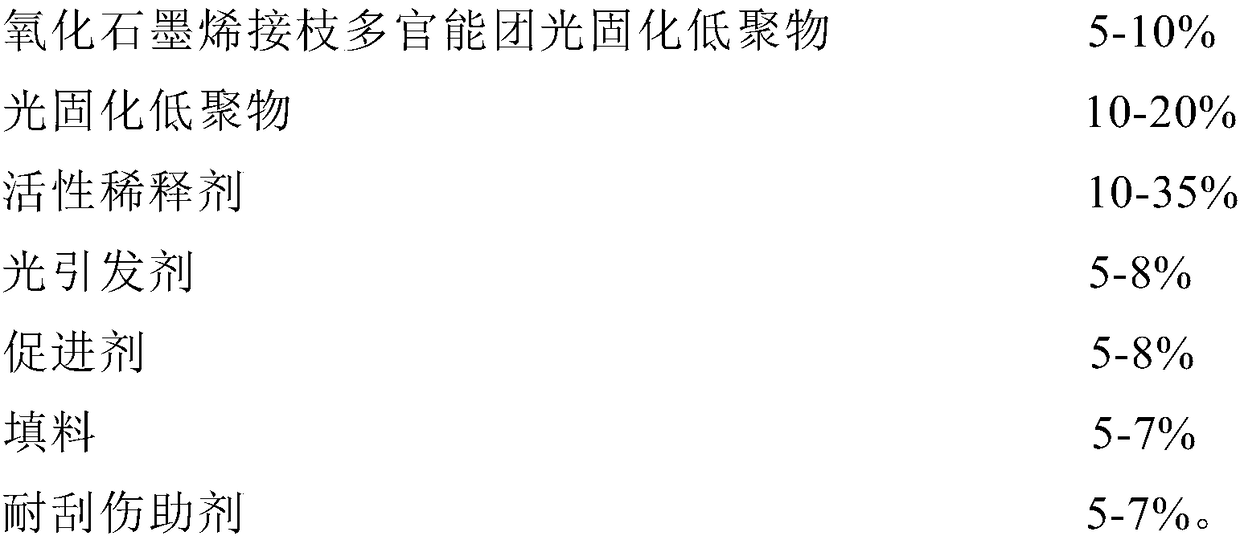

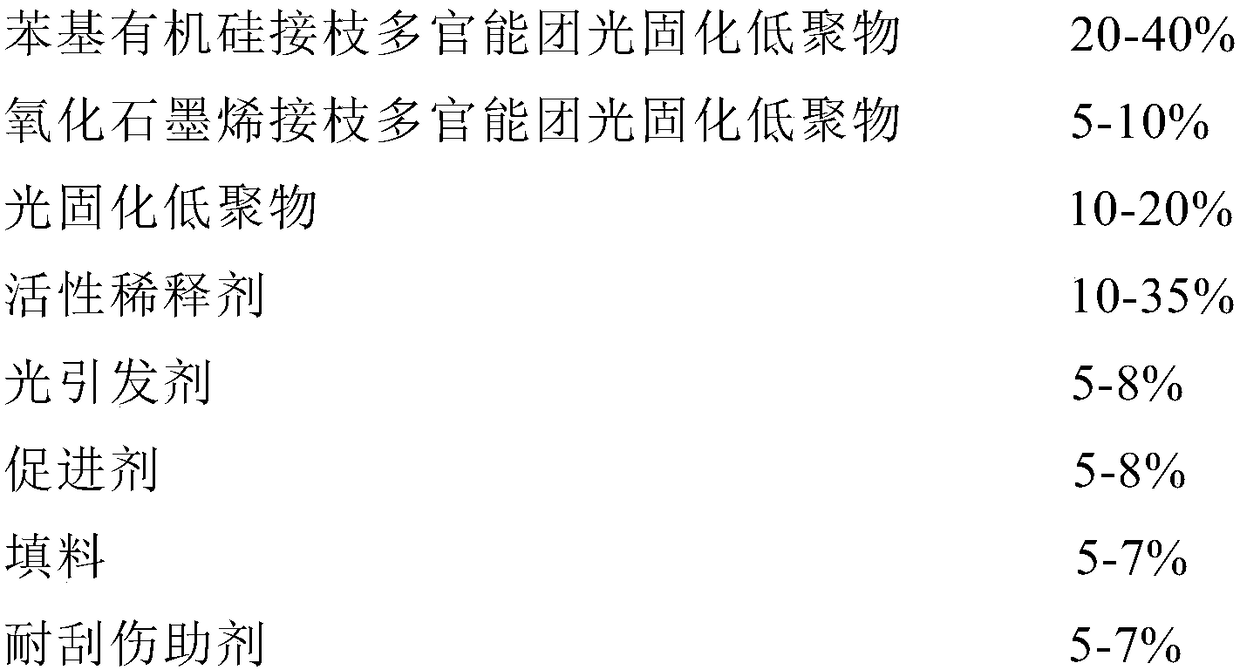

[0060] Super wear-resistant UV-cured coating, composed of the following raw materials in mass percentage:

[0061]

[0062] Among them, graphene is surface-treated by silane coupling agent KH550;

[0063] Preparation of phenyl silicone grafted hexafunctional polyurethane acrylate:

[0064] (1) Heat and dry dipentaerythritol for 4 hours at a temperature of 120°C and a vacuum of 0.1MPa, then cool to 60°C to obtain pretreated dipentaerythritol;

[0065] (2) according to the number of moles, 100 parts of pretreated dipentaerythritol and 3 parts of stannous octoate are put into the reaction vessel together, after stirring evenly, add the isophorone diisocyanate of 600 parts in moles in batches, constantly Stirring and reacting at a temperature of 80°C for 4 hours to obtain a pre-reaction base liquid;

[0066] (3) Add 20 parts of phenyltrichlorosiloxane at room temperature to the pre-reaction base liquid in parts by mole while keeping stirring, and stir for 20 minutes to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com