Culture material for industrialized cultivation of pleurotus eryngii by using waste shiitake mushroom dreg and preparation method

A technology of waste mushroom residue and Pleurotus eryngii, which is applied in the fields of mushroom cultivation, botany equipment and methods, fertilizer made from biological waste, etc., can solve the problem of affecting the annual production of Pleurotus eryngii in factories, occupying a large space, and sawdust Large demand and other issues, to achieve the effect of not reducing the biological conversion rate, sufficient sources, and increasing income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

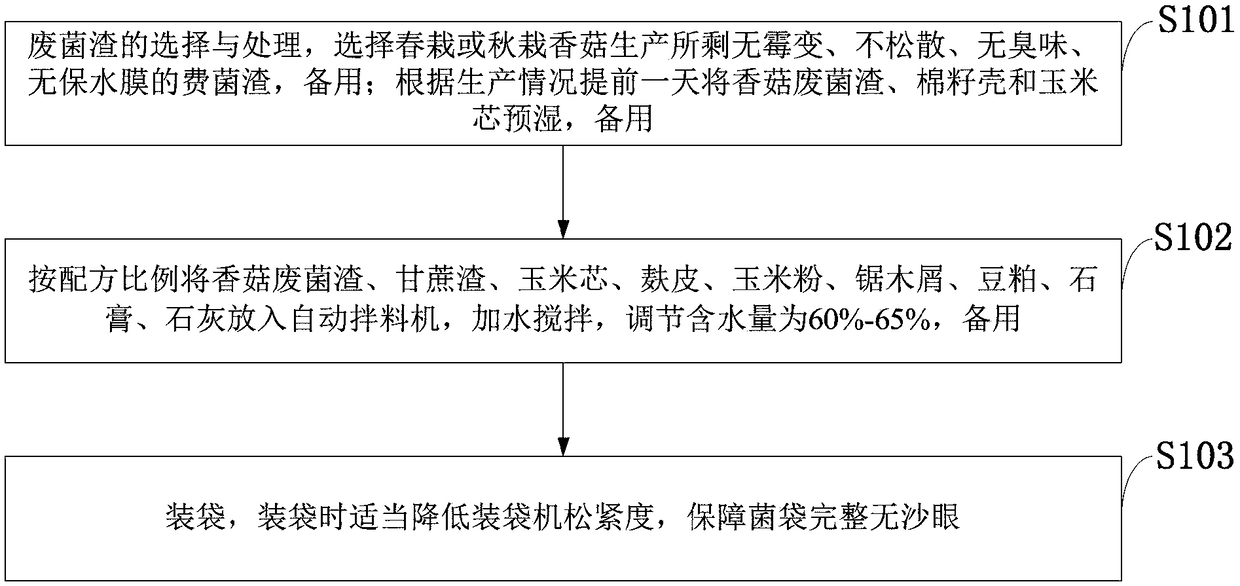

[0021] Such as figure 1 As shown, the preparation method of the compost that utilizes the waste mushroom residue of shiitake mushrooms industrialized cultivation of Pleurotus eryngii that the embodiment of the present invention provides comprises the following steps:

[0022] S101: Selection and treatment of waste fungus residues, select waste fungus residues left over from the production of spring or autumn shiitake mushrooms without mildew, looseness, odor, and water-retaining film, and reserve them; Dregs, cottonseed hulls and corncobs are pre-wetted and set aside;

[0023] S102: Put mushroom waste, bagasse, corn cob, bran, corn flour, sawdust, soybean meal, gypsum, and lime into the automatic mixer according to the formula ratio, add water and stir, and adjust the water content to 60%-65% ,spare;

[0024] S103: Packing, properly reduce the tightness of the bagging machine during bagging to ensure that the bacteria bag is complete and free of trachoma.

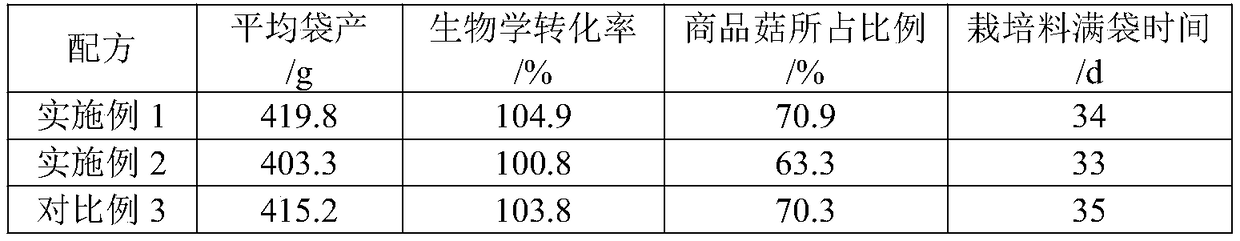

Embodiment 1

[0027] The compost for the industrialized cultivation of Pleurotus eryngii provided by the embodiments of the present invention is composed of 15% of waste mushroom residue, 10% of bagasse, 20% of corncob, 10% of cottonseed hull, and 18% of bran according to the mass percentage. , sawdust 10%, corn flour 7%, soybean meal 7%, gypsum 1.5% and lime 1.5%.

[0028] The preparation method of the compost for the industrial cultivation of Pleurotus eryngii using the waste mushroom residue of shiitake mushrooms provided by the embodiments of the present invention comprises the following steps:

[0029] A. The selection and treatment of waste fungus residues. Choose spring or autumn planted shiitake mushrooms that are free from mildew, loose, odorless, and water-retaining membranes, for use; according to the production situation, remove the waste mushrooms one day in advance. Dregs, cottonseed hulls and corncobs are pre-wetted and set aside.

[0030] B. According to the proportion of t...

Embodiment 2

[0034] The compost that utilizes the waste mushroom dregs of shiitake mushrooms provided by the embodiments of the present invention to industrially cultivate Pleurotus eryngii is composed of shiitake mushroom dregs 25%, bagasse 10%, corncobs 20%, bran 18%, sawdust 10%, Composed of 7% corn flour, 7% soybean meal, 1.5% gypsum and 1.5% lime.

[0035] The preparation method of the compost for the industrial cultivation of Pleurotus eryngii using the waste mushroom residue of shiitake mushrooms provided by the embodiments of the present invention comprises the following steps:

[0036] A. The selection and treatment of waste fungus residues. Choose spring or autumn planted shiitake mushrooms that are free from mildew, loose, odorless, and water-retaining membranes, for use; according to the production situation, remove the waste mushrooms one day in advance. Dregs, cottonseed hulls and corncobs are pre-wetted and set aside.

[0037]B. According to the proportion of the formula, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com