Feed for sheep producing high-quality wool and preparation method of feed

A quality and feed technology, applied in the field of high wool quality feed and its preparation, can solve the problems of decreased smoothness, unaffordable, single nutrition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

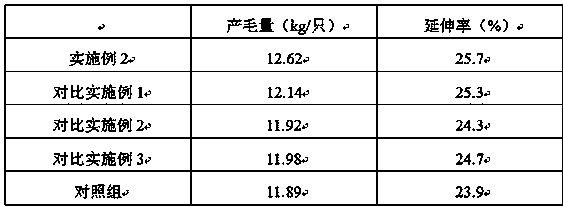

Examples

Embodiment 1

[0023] A feed for improving the quality of sheep fur, made of the following components in parts by weight: 60 parts of corn, 24 parts of wheat bran, 8 parts of soybeans, 20 parts of sweet potato vines, 8 parts of elm leaves, 7 parts of egg shells, and 6 parts of mulberry leaves , 7 parts of corn stalks, 5 parts of cod liver, 4 parts of crucian carp liver, 0.6 parts of L-calcium lactate, 0.4 parts of ferrous glycinate, 0.2 parts of iron sodium EDTA, 0.5 parts of amino acid chelated zinc, and 0.4 parts of casein phosphopeptide.

[0024] A method for preparing feed for improving wool quality, comprising the following steps:

[0025] (1) Homogenization treatment: Weigh the corresponding weight parts of cod liver and crucian carp liver and add them into the physiological saline solution with a concentration of 0.7%, and then place them in a homogenizer for homogenization treatment. The treatment time is 2 minutes. Ultrasonic treatment at a specific frequency while homogenizing;

...

Embodiment 2

[0037]A feed for improving the quality of sheep fur, made of the following components in parts by weight: 65 parts of corn, 26 parts of wheat bran, 9 parts of soybeans, 22 parts of sweet potato vines, 9 parts of elm leaves, 7.5 parts of egg shells, and 7 parts of mulberry leaves , 7.5 parts of corn stalks, 5.5 parts of cod liver, 4.5 parts of crucian carp liver, 0.7 parts of L-calcium lactate, 0.5 parts of ferrous glycinate, 0.3 parts of iron sodium EDTA, 0.6 parts of amino acid chelated zinc, and 0.5 parts of casein phosphopeptide.

[0038] A method for preparing feed for improving wool quality, comprising the following steps:

[0039] (1) Homogenization treatment: Weigh the corresponding weight parts of cod liver and crucian carp liver and add them into the physiological saline solution with a concentration of 0.8%, and then place them in a homogenizer for homogenization treatment. The treatment time is 3 minutes. Ultrasonic treatment at a specific frequency while homogenizi...

Embodiment 3

[0051] A feed for improving the quality of sheep fur, made of the following components in parts by weight: 70 parts of corn, 28 parts of wheat bran, 10 parts of soybeans, 24 parts of sweet potato vines, 10 parts of elm leaves, 8 parts of egg shells, and 8 parts of mulberry leaves , 8 parts of corn stalks, 6 parts of cod liver, 5 parts of crucian carp liver, 0.8 parts of L-calcium lactate, 0.6 parts of ferrous glycinate, 0.4 parts of iron sodium EDTA, 0.7 parts of amino acid chelated zinc, and 0.6 parts of casein phosphopeptide.

[0052] A method for preparing feed for improving wool quality, comprising the following steps:

[0053] (1) Homogenization treatment: Weigh the corresponding weight parts of cod liver and crucian carp liver and add them into the normal saline solution with a substance concentration of 0.9%, and then place them in a homogenizer for homogenization treatment. The treatment time is 4 minutes. Ultrasonic treatment at a specific frequency while homogenizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com