A kind of preparation method of straw composite adsorbent modified by magnetic chitosan and its product and application

A composite adsorption and chitosan technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve the problem of complicated modification process operation, high modifier cost, toxic drugs and other problems, to achieve broad application prospects, improve adsorption performance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

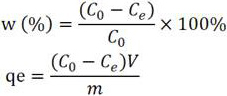

Method used

Image

Examples

Embodiment 1

[0032] 1) Preparation of magnetic nanoparticles CoFe 2 o 4

[0033] a. Weigh 6.06 g Fe(NO 3 ) 3 9H 2 O and 1.785 g CoCl 2 ·6H 2 O was dissolved in 70 mL of ethylene glycol under the condition of magnetic stirring to obtain a dark yellow solution;

[0034] b. Weigh 7.2 g CH 3 COONa was dissolved in the above solution, and magnetically stirred for 10 min to obtain a black viscous liquid;

[0035] c. Pour the above black viscous liquid into a 100 mL Teflon-lined reactor, and place the reactor in an oven at 200 °C for 8 h;

[0036] d. After the reaction is completed, the reactor is cooled to room temperature, and the solid particles generated by the reaction are separated by a magnet, washed three times with ethanol and distilled water, and dried to obtain magnetic nanoparticles CoFe 2o 4 ;

[0037] 2) Preparation of activated straw powder

[0038] a. The corn stalks collected from the countryside were dried in an oven at 40 °C for 24 hours, the skin of the stalks was ...

Embodiment 2

[0051] 1) Preparation of magnetic nanoparticles CoFe 2 o 4

[0052] With embodiment 1.

[0053] ) to prepare activated straw powder

[0054] a. The corn stalks collected from the countryside were dried in an oven at 40 °C for 24 hours, the skin of the stalks was peeled off manually, the straw core was taken out, the straw core was crushed with a grinder, and the finer straw powder was selected with a 100-mesh sieve;

[0055] b. Soak straw powder in 1.5mol / L NaOH solution for 22 hours, rinse with water until the washing solution becomes neutral;

[0056] c. adding the stalk powder that step b obtains to 5% ZnCl 2 In aqueous solution, per mL ZnCl 2 Add 0.01 g of straw powder to the solution, stir in a water bath at 70 °C for 1.5 h to obtain a colloid;

[0057] d. Suction filter the colloid, wash three times with ethanol and distilled water successively, and dry to obtain activated straw powder;

[0058] 3) Preparation of magnetic chitosan modified straw powder composite a...

Embodiment 3

[0067] 1) Preparation of magnetic nanoparticles CoFe 2 o 4

[0068] With embodiment 1.

[0069] ) to prepare activated straw powder

[0070] a. The corn stalks collected from the countryside were dried in an oven at 40 °C for 24 hours, the skin of the stalks was peeled off manually, the straw core was taken out, the straw core was crushed with a grinder, and the finer straw powder was selected with a 100-mesh sieve;

[0071] b. Soak straw powder in 2.5mol / L NaOH solution for 20 h, rinse with water until the washing solution becomes neutral;

[0072] c. adding the stalk powder that step b obtains to 15% ZnCl 2 In aqueous solution, per mL ZnCl 2 Add 0.03 g of straw powder to the solution, stir in a water bath at 72 °C for 1.5 h to obtain a colloid;

[0073] d. Suction filter the colloid, wash three times with ethanol and distilled water successively, and dry to obtain activated straw powder;

[0074] 3) Preparation of magnetic chitosan modified straw powder composite adso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com