A paper type catalyst and a preparing method thereof

A catalyst and paper-type technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of short service life and low catalyst activity, and achieve simple operation Easy to operate, good gas diffusibility, excellent mechanical properties and catalytic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

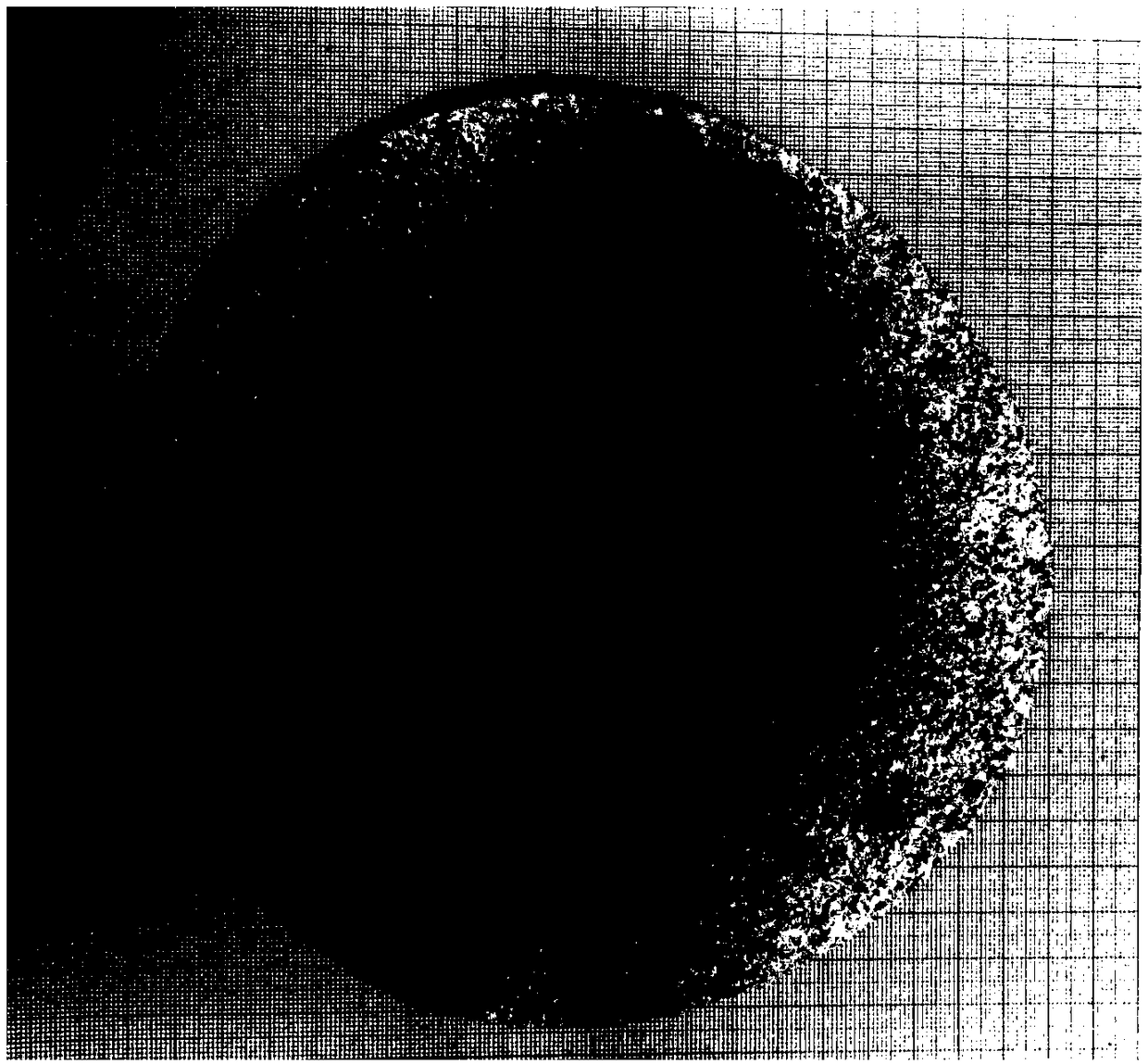

Image

Examples

Embodiment 1

[0051] The present embodiment provides a kind of sepiolite / mullite fiber paper catalyst, and its preparation method comprises the following steps:

[0052] Step 1. Grind the raw sepiolite in a mortar for 10 minutes to disperse the agglomerated fibers and powder, and sieve through 20 to 40 meshes to remove short fibers and impurity minerals to obtain sepiolite fibers. Add the sepiolite fiber to 6mol / L concentrated hydrochloric acid, the mass ratio of the sepiolite fiber and concentrated hydrochloric acid is 1:20, soak for 8h, and sieve through 40 meshes to remove a large amount of sepiolite associated minerals (talc, calcite, etc.) , washed with deionized water until neutral, dried to obtain acidified modified sepiolite fiber;

[0053] Step 2, crushing the mullite fiber, firstly crushing it, and then putting it into a material pulverizer for further pulverization, the speed of the pulverizer is 300 rpm, and the time is 10 minutes;

[0054] Step 3, be 1:0.1:0.2:0.1:0.08:350 acc...

Embodiment 2

[0058] The present embodiment provides a kind of sepiolite / mullite fiber paper catalyst, and its preparation method comprises the following steps:

[0059] Step 1. Grind the raw sepiolite in a mortar for 10 minutes to disperse the agglomerated fibers and powder, and sieve through 20 to 40 meshes to remove short fibers and impurity minerals to obtain sepiolite fibers. The foam stone fiber is added in 3mol / L concentrated hydrochloric acid, and the mass ratio of described sepiolite fiber and concentrated hydrochloric acid is 1:30, soaks 16h, sieves through 40 meshes, removes a large amount of sepiolite associated minerals (talc, calcite, etc.) , washed with deionized water until neutral, dried to obtain acidified modified sepiolite fiber;

[0060] Step 2, crushing the mullite fiber, firstly crushing it, and then putting it into a material pulverizer for further pulverization, the speed of the pulverizer is 300 rpm, and the time is 10 minutes;

[0061] Step 3, according to the ma...

Embodiment 3

[0065] The present embodiment provides a kind of sepiolite / mullite fiber paper catalyst, and its preparation method comprises the following steps:

[0066] Step 1. Grind the raw sepiolite in a mortar for 10 minutes to disperse the agglomerated fibers and powder, and sieve through 20 to 40 meshes to remove short fibers and impurity minerals to obtain sepiolite fibers. The foam stone fiber is added in 4mol / L concentrated hydrochloric acid, and the mass ratio of described sepiolite fiber and concentrated hydrochloric acid is 1:40, soaks 12h, sieves through 40 meshes, removes a large amount of sepiolite associated minerals (talc, calcite, etc.) , washed with deionized water until neutral, dried to obtain acidified modified sepiolite fiber;

[0067] Step 2, crushing the mullite fiber, firstly crushing it, and then putting it into a material pulverizer for further pulverization, the speed of the pulverizer is 300 rpm, and the time is 10 minutes;

[0068] Step 3, according to the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com