Molybdenum-based catalyst, and preparation method and application thereof

A molybdenum-based catalyst, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as less propionic acid work, and achieve improved hydrogenolysis capacity, long stable period, high commercial The effect of developing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

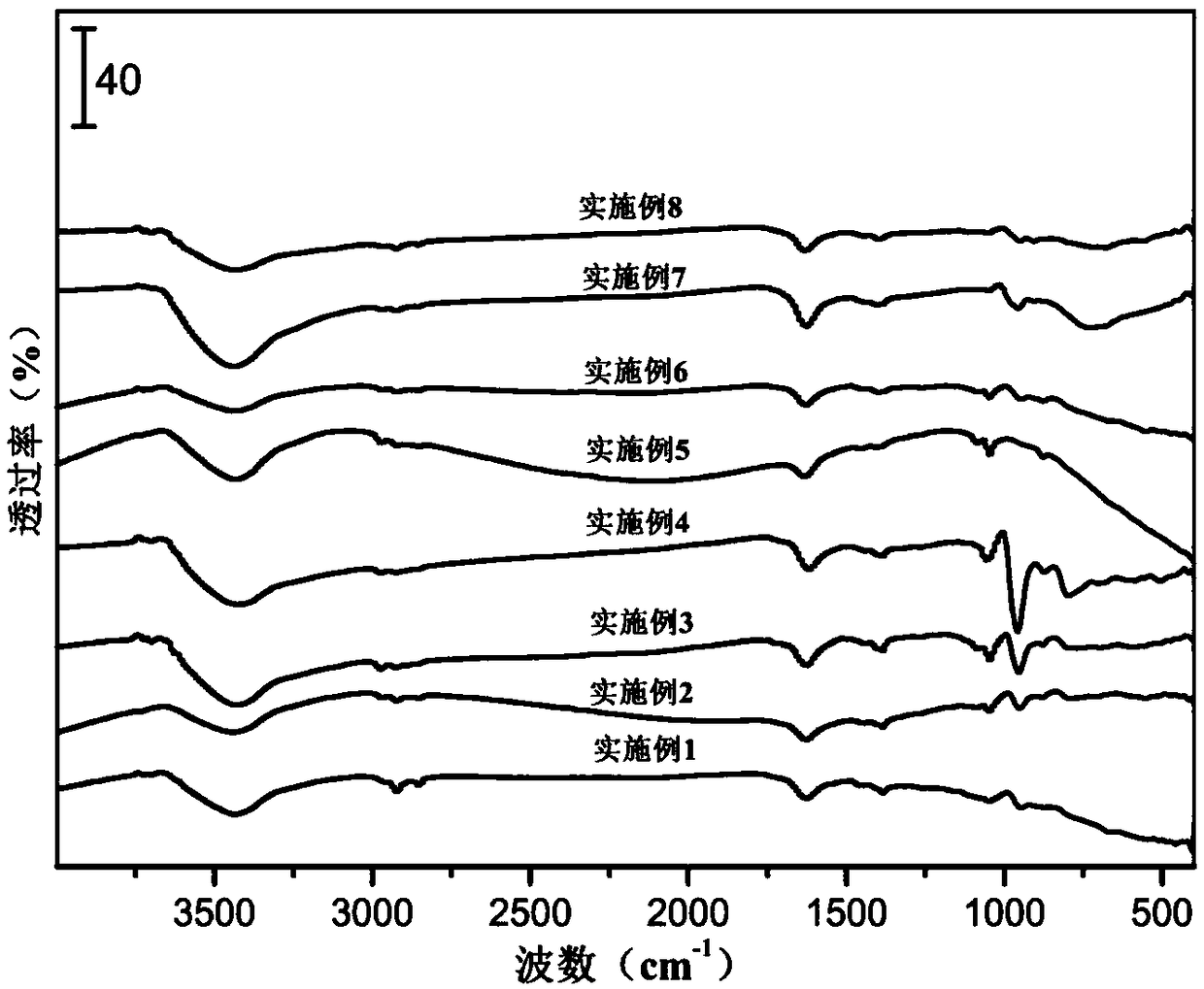

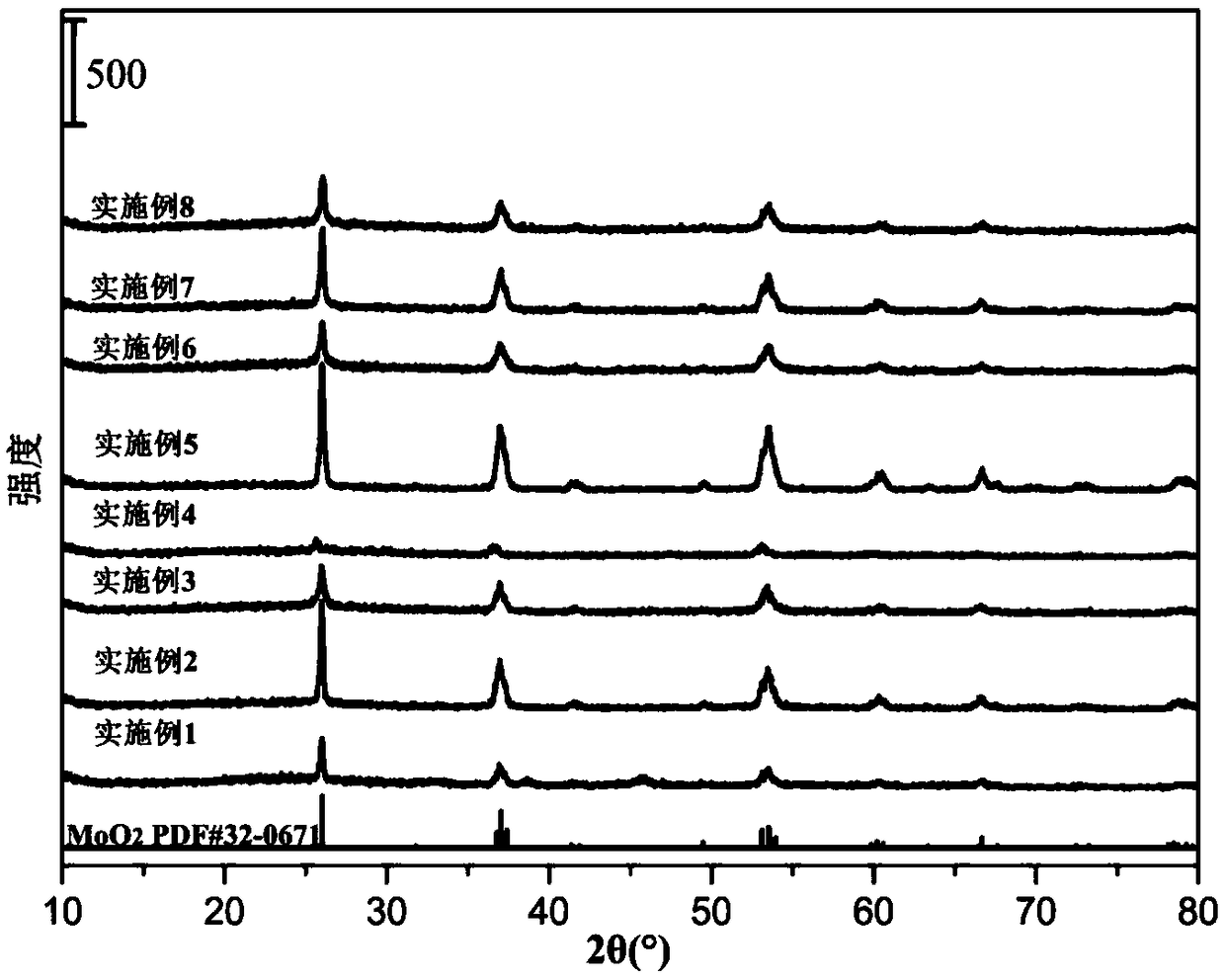

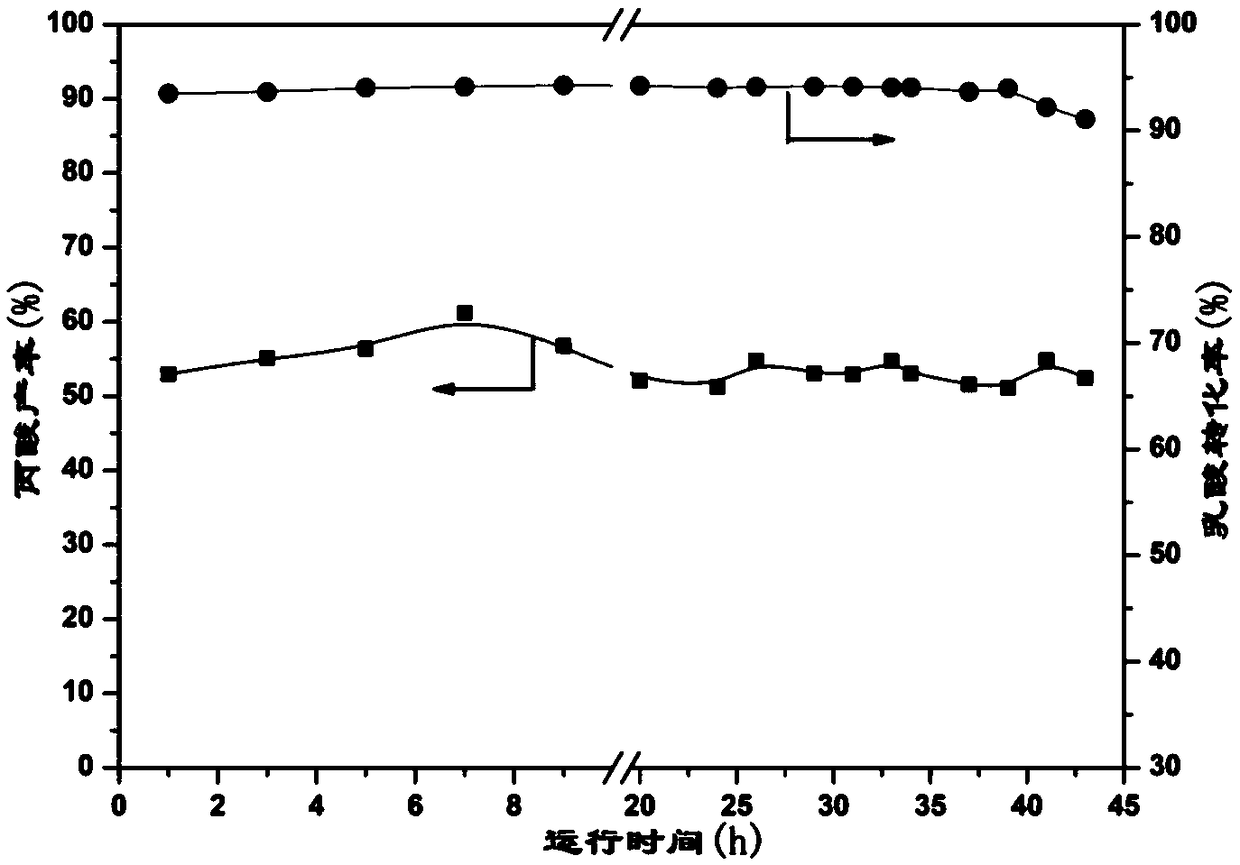

Embodiment 1

[0032] Take 0.72g molybdenum trioxide and add 15mL H 2 o 2 – Fully stir in the mixed solution of ethanol (volume ratio: 1:1) for 30 minutes, raise the temperature to 60°C and then add 0.12 g of egg whites after the solution turns yellow, continue stirring for 1 hour, stop stirring, raise the temperature to 100°C and steam dry to obtain the corresponding catalyst precursor. A quartz tube with a length of 400 mm and an inner diameter of 4 mm was selected, and 0.50 g of the above spare catalyst was packed into the quartz tube. The length of the catalyst in the tube was 30 mm, and both ends of the catalyst were sealed with quartz wool. After the catalyst is loaded and the fixed bed reactor is installed, the carrier gas is turned on, and the temperature of the fixed bed is raised to 390°C at a rate of 8°C / min. After stabilizing for 30 minutes, materials are introduced into the reactor. The nitrogen gas carries the lactic acid aqueous solution through the above-mentioned quartz tu...

Embodiment 2

[0034] Take 0.88g ammonium molybdate and add 15mL H 2 o 2 – Fully stir in the mixed solution of ethanol (1:1 by volume) for 30 minutes, the solution turns yellow, raise the temperature to 60°C, add 0.12g protein, continue stirring for 1 hour, stop stirring, raise the temperature to 100°C and evaporate to dryness , that is, the corresponding catalyst precursor is obtained. A quartz tube with a length of 400 mm and an inner diameter of 4 mm was selected, and 0.20 g of the above spare catalyst was packed in the quartz tube. The length of the catalyst in the tube was 30 mm, and both ends of the catalyst were sealed with quartz wool. After the catalyst is loaded and the fixed bed reactor is installed, the carrier gas is turned on, and the temperature of the fixed bed is raised to 390°C at a rate of 8°C / min. After stabilizing for 30 minutes, materials are introduced into the reactor. The nitrogen gas carries the lactic acid aqueous solution through the above-mentioned quartz tube ...

Embodiment 3

[0036] Take 0.76g phosphomolybdic acid and add 15mL H 2 o 2 – Fully stir in the mixed solution of ethanol (1:1 by volume) for 30 minutes, the solution turns yellow, raise the temperature to 60°C, add 0.12g protein, continue stirring for 1 hour, stop stirring, raise the temperature to 100°C and evaporate to dryness , that is, the corresponding catalyst precursor is obtained. A quartz tube with a length of 400 mm and an inner diameter of 4 mm was selected, and 0.20 g of the above spare catalyst was packed in the quartz tube. The length of the catalyst in the tube was 30 mm, and both ends of the catalyst were sealed with quartz wool. After the catalyst is loaded and the fixed bed reactor is installed, the carrier gas is turned on, and the temperature of the fixed bed is raised to 390°C at a rate of 8°C / min. After stabilizing for 30 minutes, materials are introduced into the reactor. The nitrogen gas carries the lactic acid aqueous solution through the above-mentioned quartz tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com