A kind of benzoxazine resin containing carbon nitrogen and azo structure and preparation method thereof

A benzoxazine and azo technology, applied in the field of benzoxazine resin and its preparation, can solve problems such as single function, application range and application field limitations, achieve low volume shrinkage, expand application market and prospects, The effect of good film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

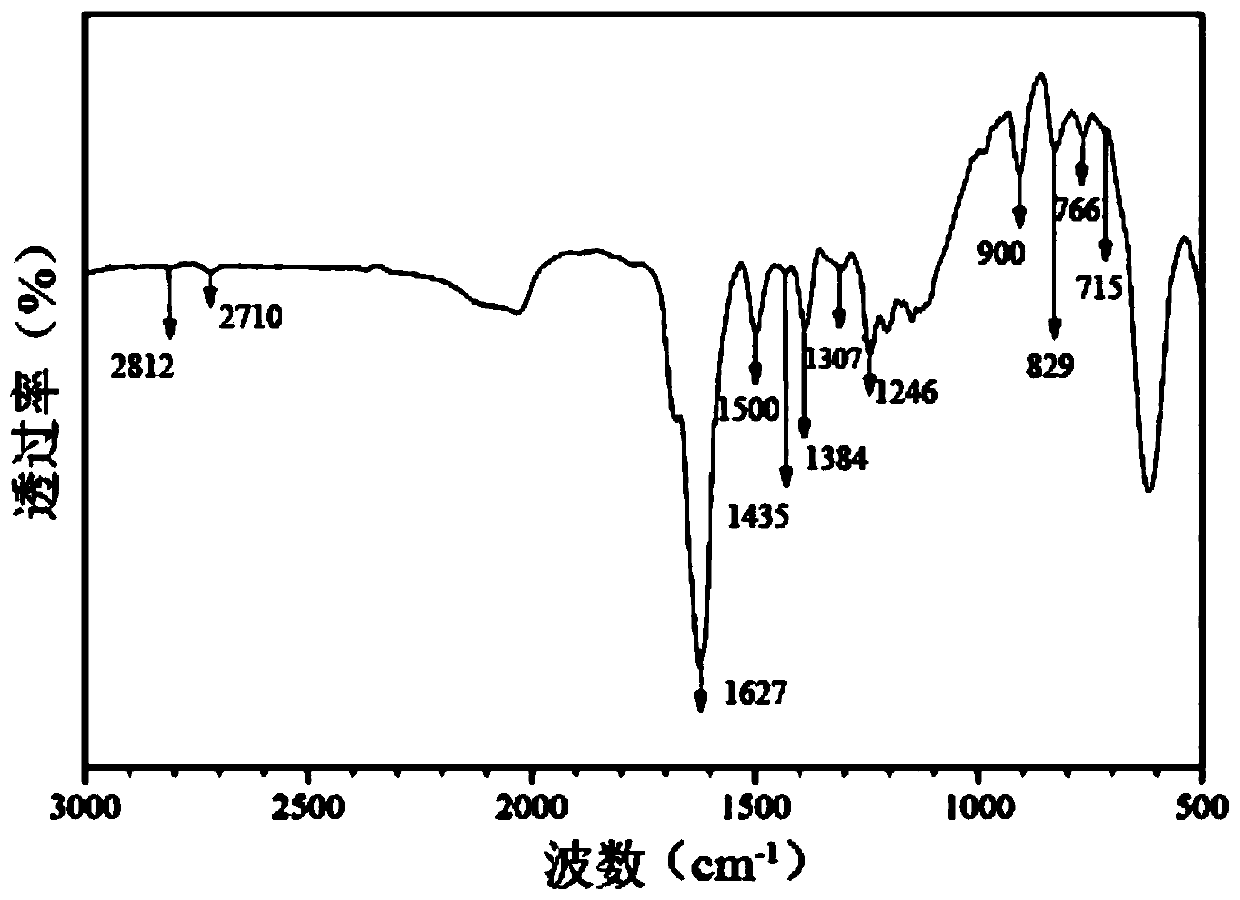

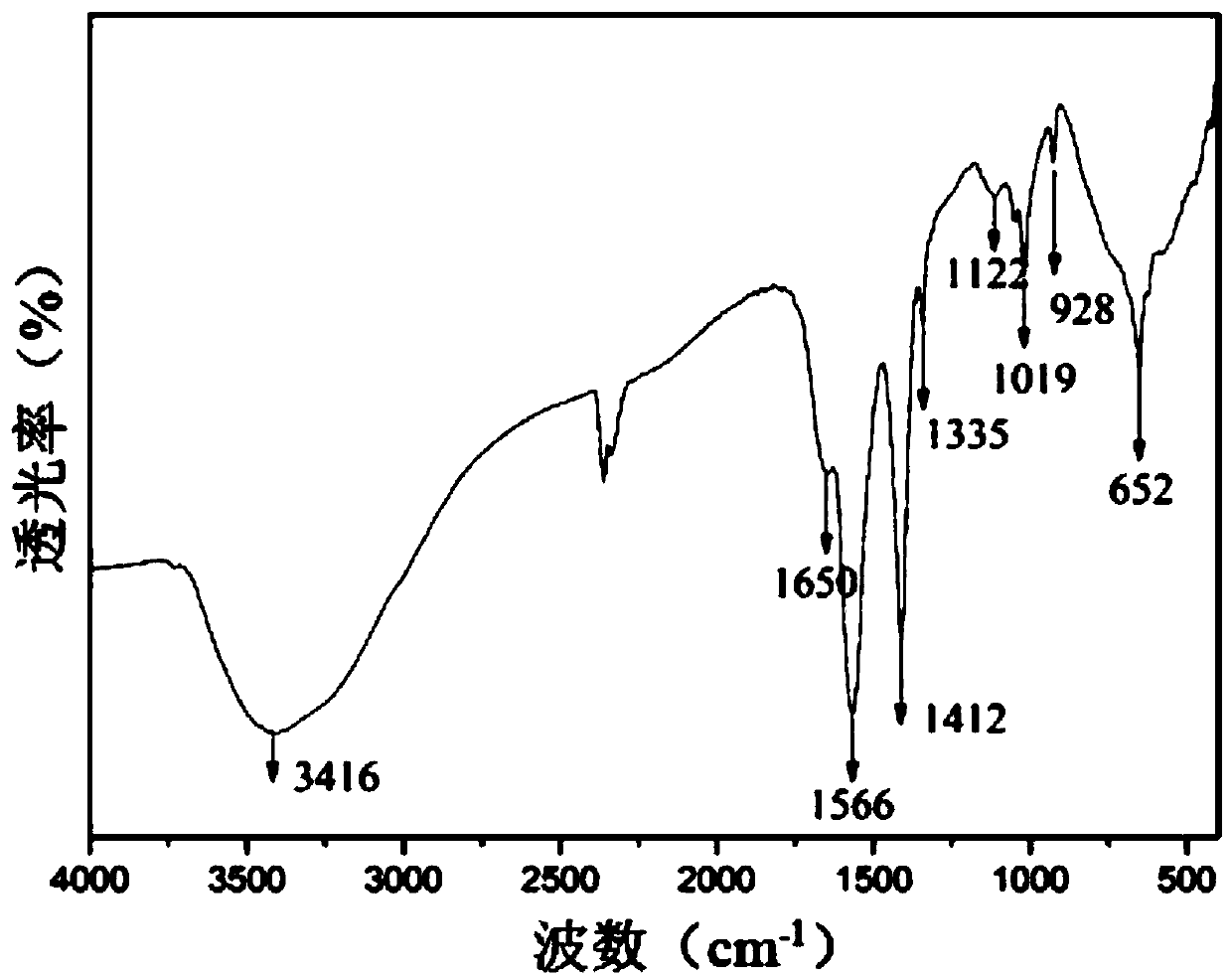

[0029] A kind of preparation method of the benzoxazine resin containing carbon nitrogen and azo structure, comprises the steps:

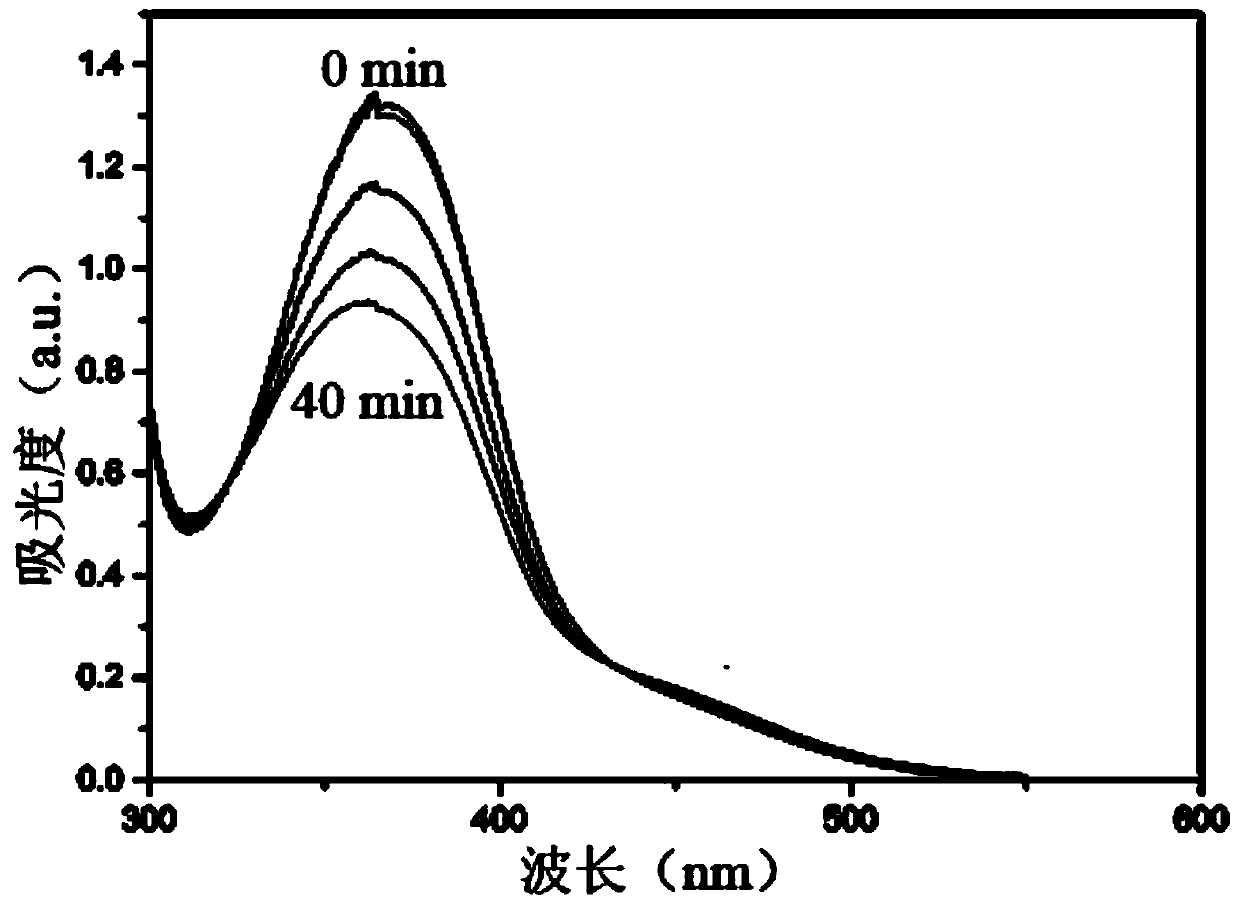

[0030] S1. Add 40 parts by weight of paraformaldehyde and 200 parts by weight of 4-aminoazobenzene (primary amine A) into the reactor, add 500 parts by weight of toluene, and mechanically stir at 300 rpm for 0.5 h at 30°C. Obtain the mixed solution; S2. Slowly add 125 parts by weight of p-hydroxybenzaldehyde to the mixed solution system, then raise the temperature to 120° C. and reflux for 6 hours under mechanical stirring at 400 rpm. After the reaction is completed, cool the system to room temperature, and After alkali washing and water washing for 3 times, the organic phase is separated, and the toluene is removed by rotary evaporation, and the product is dried to obtain an intermediate containing carbon nitrogen and azo structure; S3, 175 parts by weight of the intermediate prepared in step S2 and 180 parts by weight of Add N-phenyl-1,4-phenylene...

Embodiment 2

[0039] A kind of preparation method of the benzoxazine resin containing carbon nitrogen and azo structure, comprises the steps:

[0040] S1. Add 65 parts by weight of paraformaldehyde and 210 parts by weight of 4,4'-azodiphenylamine (primary amine A) into the reactor, add 1000 parts by weight of p-xylene, and set the temperature at 50°C at 500 rpm Stir mechanically for 1 hour to obtain a mixed solution; S2. Slowly add 250 parts by weight of o-hydroxybenzaldehyde to the mixed solution system, then raise the temperature of the system to 120° C., and reflux for 6 hours under mechanical stirring at 400 rpm. After the reaction is completed, the The system was cooled to room temperature, after washing with alkali and water for 4 times, the organic phase was separated, the toluene was removed by rotary evaporation, and the product was dried to obtain an intermediate containing an azo structure; S3, 300 parts by weight of an intermediate containing an azo structure and 150 parts by we...

Embodiment 3

[0043] A kind of preparation method of the benzoxazine resin containing carbon nitrogen and azo structure, comprises the steps:

[0044] S1. Add 30 parts by weight of paraformaldehyde and 90 parts by weight of aniline (primary amine A) into the reactor, add 400 parts by weight of p-xylene, and mechanically stir at 300 rpm at 60°C for 1 hour to obtain a mixed solution; S2. Add 120 parts by weight of p-hydroxybenzaldehyde to the mixed liquid system. After the p-hydroxybenzaldehyde is added, the system is refluxed for 4 hours under the condition of 140° C. and 400 rpm mechanical stirring. After the reaction was completed, the system was cooled to room temperature, washed twice with alkali and water, the organic phase was separated, the toluene was removed by rotary evaporation, and the product was dried to obtain an intermediate without an azo structure; S3, 240 parts by weight of The azo-containing intermediate and 195 parts by weight of 4-aminoazobenzene (primary amine B) were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com