A kind of monoatomic cobalt-based methanol fuel and its preparation method

A methanol fuel and atomic technology, applied in fuel, fuel additive, liquid carbon-containing fuel, etc., can solve problems such as incomplete combustion, low calorific value and instability of methanol fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

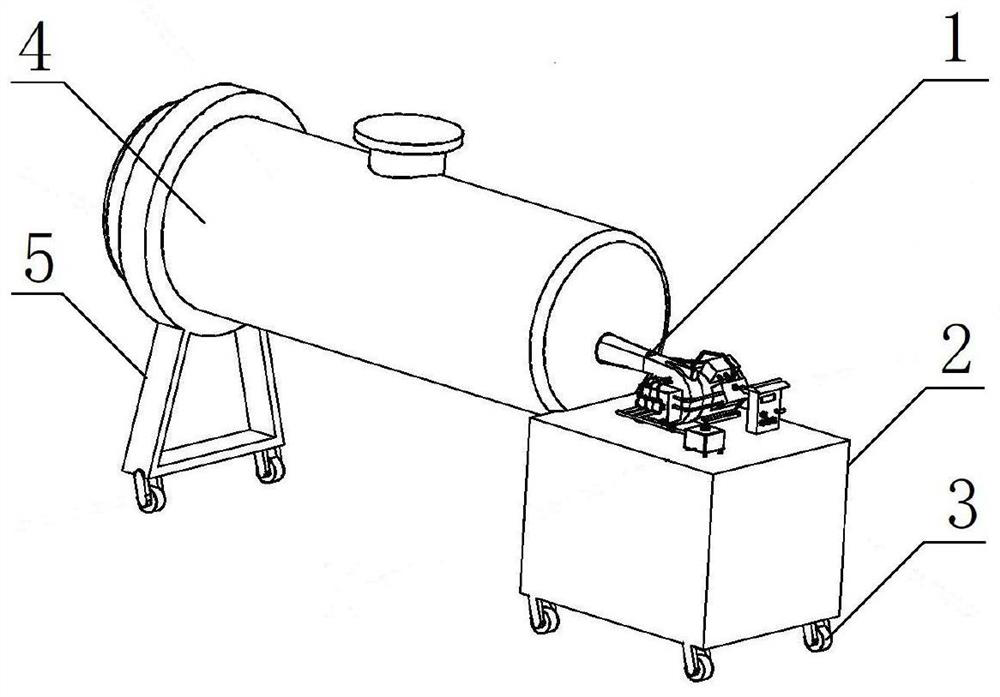

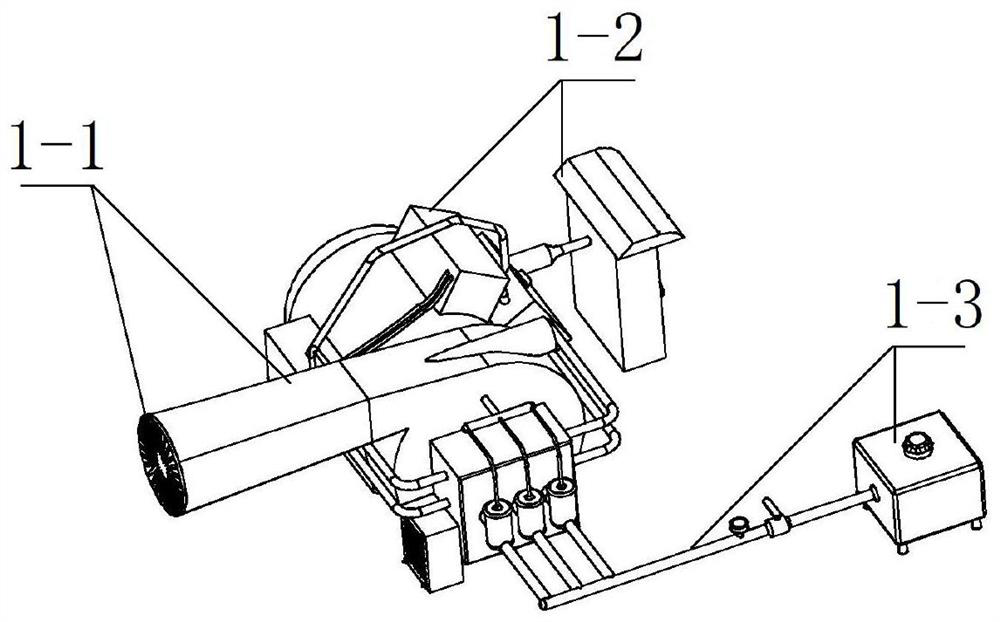

Method used

Image

Examples

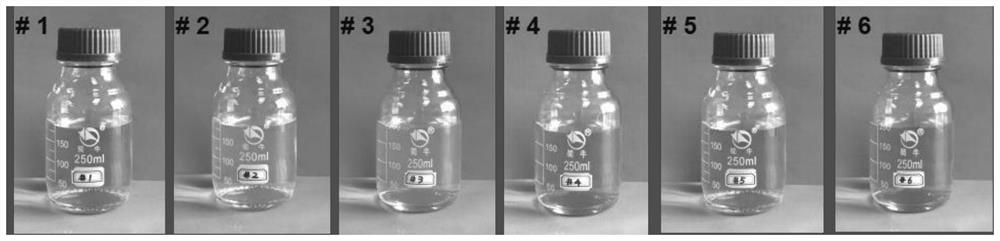

Embodiment 1

[0042] No. 1 methanol fuel, single-atom cobalt-based catalyst: Co-N-C catalyst 1.6%, co-solvent: ethanol 26%, acetone 13%, combustion improver: xylene 14%, oxygen enhancer: hydrogen peroxide 27%, potassium nitrate 0.4%, Cleaning agent: polyether amine 8%, lubricant: glycerol 10%; first mix co-solvent, combustion aid, oxygen enhancer, detergent, lubricant and single-atom cobalt-based catalyst in order to make composite additives, dissolve Finally, add the pH regulator sodium hydroxide to adjust the pH of the solution to neutral, then add the methanol to the composite additive at a weight ratio of 100:5 by weight, and stir for 30 minutes to obtain the monoatomic cobalt-based methanol fuel .

Embodiment 2

[0044] No. 2 methanol fuel, single-atom cobalt-based catalyst: Co-N-C catalyst 1.7%, co-solvent: ethanol 28%, acetone 14%, combustion aid: isopropanol 7%, oxygen enhancer: hydrogen peroxide 29%, potassium nitrate 0.5% , cleaning agent: polyether amine 8.8%, lubricant: glycerol 11%; preparation and use method are the same as embodiment 1.

Embodiment 3

[0046] No. 3 methanol fuel, single-atom cobalt-based catalyst: Co-N-C catalyst 2%, co-solvent: ethanol 29%, acetone 15%, combustion aid: ferrocene 1.5%, oxygen enhancer: hydrogen peroxide 31%, potassium nitrate 0.5% , cleaning agent is polyether amine 9%, lubricant: glycerol 12%; preparation and use method are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com