Single-atom metal photocatalyst and its preparation method and application in carbon-oxygen cross-coupling reaction

A catalyst and metal light technology, applied in the research and development of single-atom metal photocatalysts, can solve the problems of poor cycle utilization, limited electron or energy transfer efficiency in the initiation step, and deactivation of metal deposition, so as to improve atomic efficiency and avoid Deposition of inactivation to achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

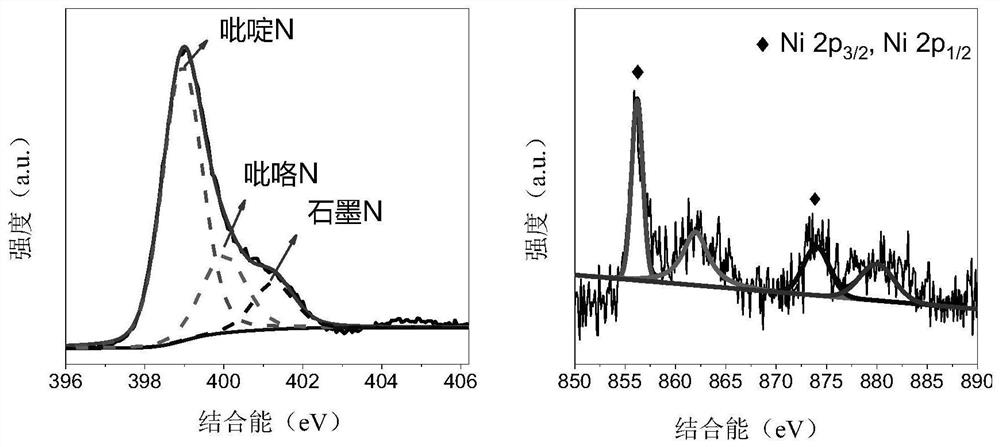

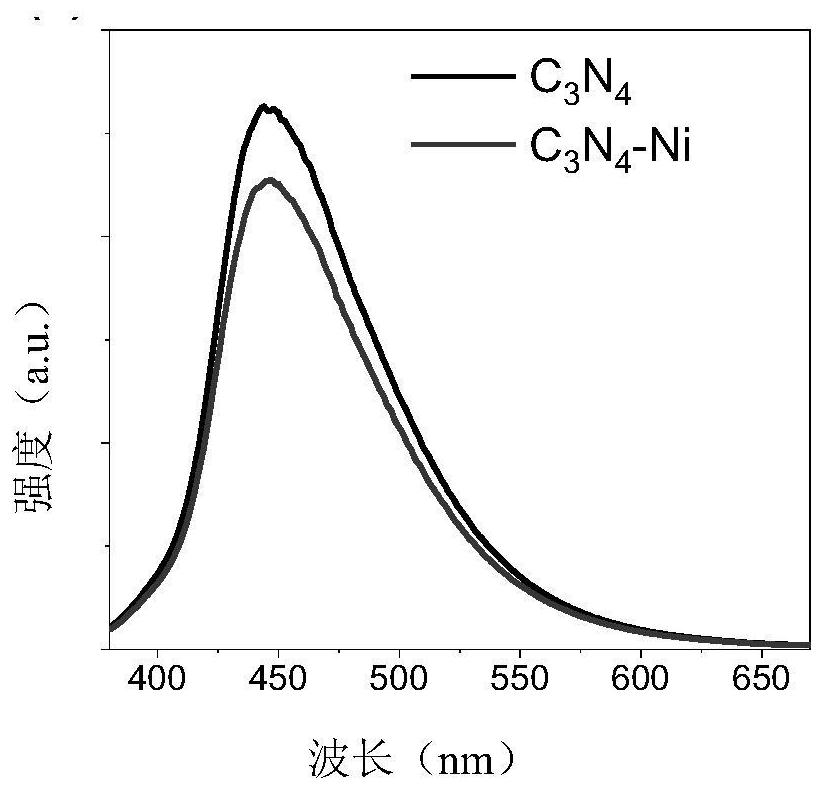

Embodiment 1

[0044] 10g of urea was heated to 500°C at a heating rate of 2°C / min, and kept at 500°C in air for 2 hours. The obtained yellow solid product was triturated and washed with water and ethanol. The sample was vacuum dried for 12 h to obtain C 3 N 4 . By adding 1mmol / L nickel chloride hexahydrate, C 3 N 4 (2g / L) was dispersed in a suspension of 50mL DMAc and reacted for 6 hours. It was then centrifuged, and the solid product was washed twice, then dried under vacuum for 12 h. get C 3 N 4 Loaded mononuclear nickel.

Embodiment 2

[0046] 10mg C 3 N 4 -Ni and 0.02 mmol of auxiliary ligand imidazole, 0.18 mmol of organic base, 0.1 mmol of p-bromoacetophenone and 6 mmol of methanol were added to (DMAc), and the total volume of the reaction solution was 5 mL. The reaction mixture was then purged with argon for at least 15 minutes under magnetic stirring to remove oxygen. Photoreactions were performed under the illumination of a xenon lamp equipped with a 400 nm stop filter. The reaction temperature was maintained at 25°C with circulating water cooling. After 8 hours of irradiation, the product p-methoxyacetophenone was obtained with a yield of 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com