Preparation method of thermostable chitosanase

A chitosanase and thermostable technology, which is applied in the field of preparation of thermostable chitosanase, can solve the problems of difficulty in large-scale production and wide application, low enzyme yield and low enzyme activity of enzyme-producing strains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

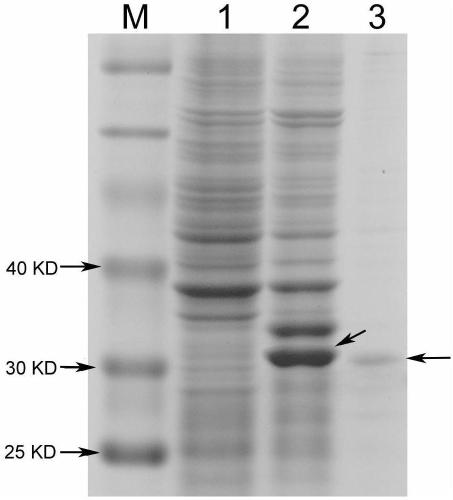

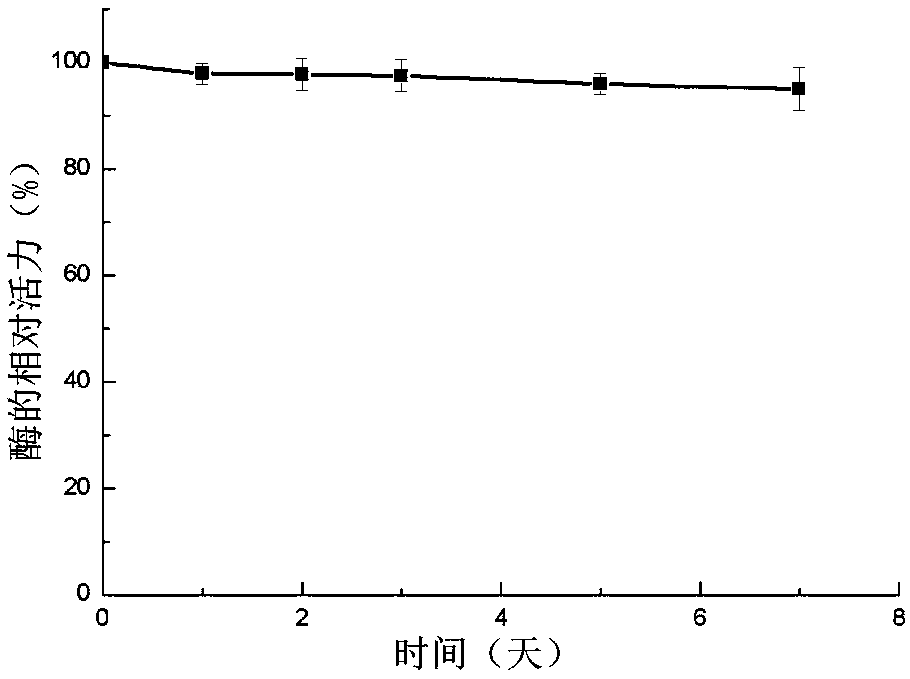

Image

Examples

Embodiment 1

[0050] Embodiment 1 A kind of preparation method of thermostable chitosanase, concrete steps are as follows:

[0051] 1. Cloning of chitosanase BmCsn

[0052] (1) Obtaining the partial sequence of chitosanase BmCsn

[0053] The strain with high chitosanase catalytic activity comes from the sandy soil in the coastal zone of Yantai, and the strain is identified as Bacillus mojavensis. Since the genome sequence of B. mojavensis has not been published yet, degenerate primers were designed by using the sequence alignment of other chitosanases from Bacillus, and the upstream primer BmCsn-partialF was 5'-GAAAGCGATGACATMAGCAA-3' (SEQ ID NO. 1), the downstream primer BmCsn-partialR is 5'-ACACGGGCAACHGATTCTCTCC-3' (SEQ ID NO.2), and the partial sequence BmCsn-partial (SEQ ID NO.3) of B. mojavensis chitosanase is obtained. Sequencing results showed that the partial sequence was the partial sequence of chitosanase BmCsn.

[0054] (2) Chromosome walking method to obtain the full-length ...

Embodiment 2

[0066] Embodiment 2 A kind of preparation method of thermostable chitosanase, concrete steps are as follows:

[0067] 1. Culture medium preparation

[0068] (1) Solid preservation medium: yeast extract powder 5g / L, peptone 10g / L, NaCl 5g / L, kanamycin 100mg / L, agar 20g / L, pH 7.0, autoclaved at 121°C for 20min;

[0069] (2) Liquid seed medium: yeast extract powder 1-10g / L, peptone 10g / L, NaCl 5g / L, kanamycin 100mg / L, pH 7.0, sterilized by high pressure steam at 121°C for 20min;

[0070] (3) Fermentation medium: glucose 20g / L, yeast extract powder 10, peptone 20g / L, MgSO 4 40.5, NaCl 2.5, KH 2 PO42, CaCl 20.1, pH 6.5, sterilized by high pressure steam at 121°C for 20min.

[0071] 2. Strain activation: pick the chitosanase engineering bacteria BL21-BmCsn strain obtained in Example 1 and inoculate it into a solid preservation medium by streaking and inoculating it in a constant temperature incubator at 37° C. for 14 to 20 hours;

[0072] 3. Preparation of liquid seeds: pick the...

Embodiment 3

[0075] Embodiment 3 A kind of preparation method of thermostable chitosanase, concrete steps are as follows:

[0076] (1) The acquisition of chitosanase engineered bacteria BL21-BmCsn is the same as in Example 1.

[0077] (2) The preparation of the culture medium is the same as in Example 2.

[0078] (3) The fermentation condition of chitosanase is as follows: insert liquid seed into fermentation medium by 5% inoculum size, rotating speed 200r / min, pH7.0, bacterium liquid cultivates 2-3 hour at 37 ℃, to OD 600 Add 0.3% lactose to induce at ≈0.3-0.5, cool down to 28°C after lactose induction, and ferment for 16 hours. After the end, centrifuge at 6000rpm for 10min to obtain wet bacteria containing chitosanase, and the activity of chitosanase reaches The highest value is 750U / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com