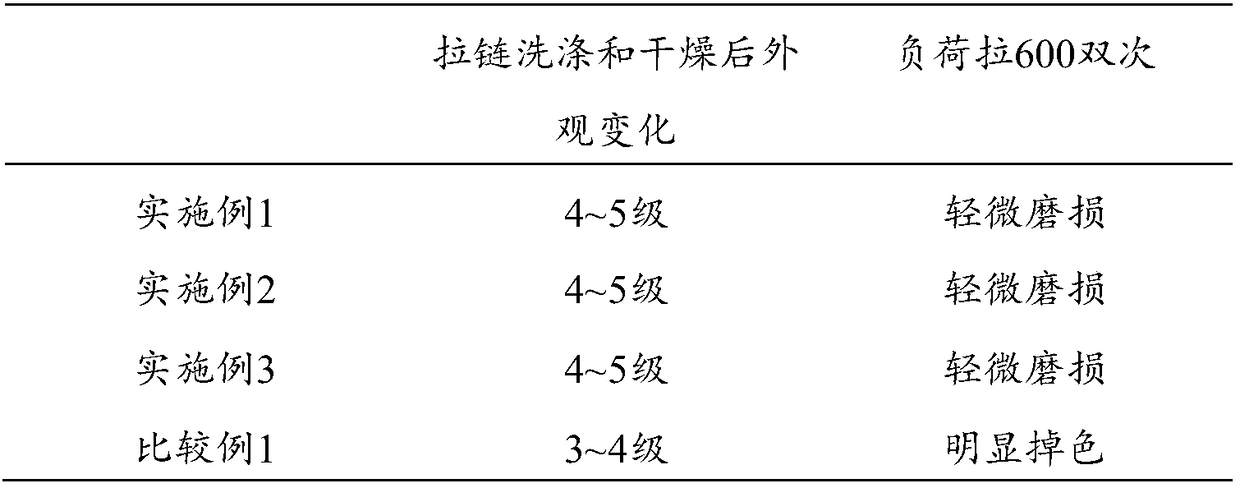

Metal zipper coloring agent, metal zipper and preparation method thereof

A metal zipper and coloring agent technology, applied in the field of zipper production, can solve problems such as delamination and paint falling, and achieve the effect of excellent coloring quality, not easy to fade, and excellent load resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a kind of preparation method of metal slide fastener, comprises the following steps:

[0060] A) degreasing the teeth of the metal zipper;

[0061] B) cleaning and coloring the degreased teeth to obtain colored teeth;

[0062] C) cleaning and dehydrating the colored teeth;

[0063] D) oiling the dehydrated teeth to obtain a metal zipper;

[0064] The coloring agent used in the coloring is the metal zipper coloring agent mentioned above.

[0065] In some embodiments of the present invention, the metal zipper is a brass zipper.

[0066] The present invention first degreases the teeth of the metal zipper to remove the oil stains on the teeth of the metal zipper. The degreasing agent used for the degreasing is preferably an alkaline degreasing agent. In some embodiments of the present invention, the degreaser is a commercially available alkaline degreaser HP-201A.

[0067]Before the degreasing, it is preferable to polish the teeth o...

Embodiment 1

[0093] Use a grinding machine to mechanically grind the teeth of the brass zipper;

[0094] Degreasing the zipper teeth: put in alkaline degreasing agent HP-201A to remove the oil on the zipper teeth;

[0095] Clean the zipper teeth with clean water;

[0096] Then, coloring is carried out in the coloring water, and the formula of the coloring agent is as follows:

[0097] Sodium chlorite: 80g / L;

[0098] Sodium hydroxide: 60g / L;

[0099] Sodium sulfate: 20g / L;

[0100] Water: balance.

[0101] Coloring temperature: 40°C; Coloring time: 3min;

[0102] After the coloring is completed, clean the zipper teeth with clean water;

[0103] dehydration;

[0104] The surface of the chain teeth is coated with epoxy resin paint commonly used in the zipper industry by using a box-type racking machine;

[0105] Drying; the drying temperature is 130°C; the drying time is 12 minutes.

Embodiment 2

[0108] Use a grinding machine to mechanically grind the teeth of the brass zipper;

[0109] Degreasing the zipper teeth: put in alkaline degreasing agent HP-201A to remove the oil on the zipper teeth;

[0110] Clean the zipper teeth with clean water;

[0111] Then, coloring is carried out in the coloring water, and the formula of the coloring agent is as follows:

[0112] Sodium chlorite: 50g / L;

[0113] Sodium hydroxide: 20g / L;

[0114] Sodium sulfate: 70g / L;

[0115] Water: balance.

[0116] Coloring temperature: 20°C; Coloring time: 5min;

[0117] After the coloring is completed, clean the zipper teeth with clean water;

[0118] dehydration;

[0119] The surface of the chain teeth is coated with epoxy resin paint commonly used in the zipper industry by using a box-type racking machine;

[0120] Drying; the drying temperature is 140°C; the drying time is 10min.

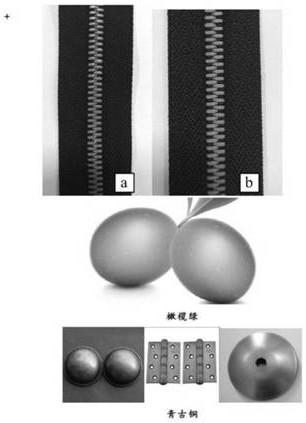

[0121] The color of the brass zipper observed by the naked eye is olive, such as figure 1 shown, from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com