Preparation method of hollow titanium dioxide microspheres

A technology of titanium dioxide and hollow microspheres, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high cost and troublesome preparation process, and achieve the effects of uniform size, controllable shell thickness and convenient source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

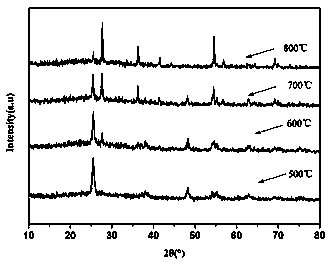

[0024] A preparation method of hollow titanium dioxide microspheres, the preparation process is as follows Figure 4 Shown:

[0025] The first step, the preparation of the template containing carboxyl copolymer microspheres on the surface: add deionized water, styrene (St), methacrylic acid (MAA), water-soluble initiator in sequence in the reactor, under nitrogen, heat up and stir, and react After centrifugation, separation, washing, and drying, the polymer microsphere template containing carboxyl groups on the surface is obtained; in terms of weight fraction, 100 parts of deionized water, 10 parts of styrene (St), and 1-3 parts of methacrylic acid (MAA) , 0.03-0.065 parts of water-soluble initiator;

[0026] The second step, the preparation of the positively charged template microsphere emulsion on the surface: add polymer microspheres, cationic surfactant, absolute ethanol, deionized water in the reactor successively, and ultrasonically disperse to form a white emulsi...

Embodiment 1

[0030] The first step, the preparation of the template containing carboxyl copolymer microspheres on the surface: add 100 parts of deionized water, 10 parts of styrene (St), and 1 part of methacrylic acid (MAA) in a 250ml four-necked flask, and raise the temperature under nitrogen , with mechanical stirring at a stirring rate of 200r / min. When the reaction temperature rose to 60°C, 0.03 parts of potassium persulfate (KPS) was added at one time to react for 8 hours, and then the reaction was terminated. centrifugation and separation, the centrifugation rate is 6000r / min, the centrifugation time is 5min, washing, vacuum drying, the drying temperature is 60°C, and the drying time is 6h, to obtain the polymer microsphere template containing carboxyl groups on the surface;

[0031] The second step, the preparation of positively charged template microsphere emulsion on the surface: add 0.2 parts of polymer microspheres, 0.03 parts of cetyltrimethylammonium bromide (CTAB) as a cationi...

Embodiment 2

[0035]The first step, the preparation of the template containing carboxyl copolymer microspheres on the surface: add 100 parts of deionized water, 10 parts of styrene (St), and 2 parts of methacrylic acid (MAA) in a 250ml four-neck flask, and raise the temperature under nitrogen , with mechanical stirring at a stirring rate of 200r / min. When the reaction temperature rose to 65°C, 0.04 parts of potassium persulfate (KPS) was added at one time to react for 10 hours, and then the reaction was terminated. centrifugation and separation, the centrifugation rate is 6000r / min, the centrifugation time is 5min, washing, vacuum drying, the drying temperature is 60°C, and the drying time is 6h, to obtain the polymer microsphere template containing carboxyl groups on the surface;

[0036] The second step, the preparation of the positively charged template microsphere emulsion on the surface: add 0.2 parts of polymer microspheres, 0.045 parts of cetyltrimethylammonium bromide (CTAB) as the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com