Surface alloying method for high current pulse electron beam irradiation TC4 titanium alloys

A technology of electron beam irradiation and surface alloying, which is applied in the field of titanium alloy surface alloying, can solve the problems of poor wear resistance and low hardness of TC4 titanium alloy, so as to slow down the oxidation rate, improve the oxidation resistance and increase the strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of alloyed modified layer:

[0030] In the first step, the annealed industrial TC4 titanium alloy bar is selected, and the sample is made into a sample of Φ12×5mm by a wire cutting machine tool.

[0031] The surface of the sample was polished with 150, 400, 800, 1000, 1500, 2000 and 2500 mesh metallographic sandpaper, respectively. Among them, the diamond polishing agent with a particle size of 0.5 μm is selected as the polishing agent, and finally cleaned by ultrasonic cleaning with acetone and absolute ethanol before use.

[0032] In the second step, the Cr powder and the organic binder are mixed uniformly at a ratio of 9g / 100mL to prepare a slurry, and finally the slurry is uniformly coated on the surface of the sample after ultrasonic cleaning to form a coating layer, and the thickness of the coating layer is 78 μm, dry in air.

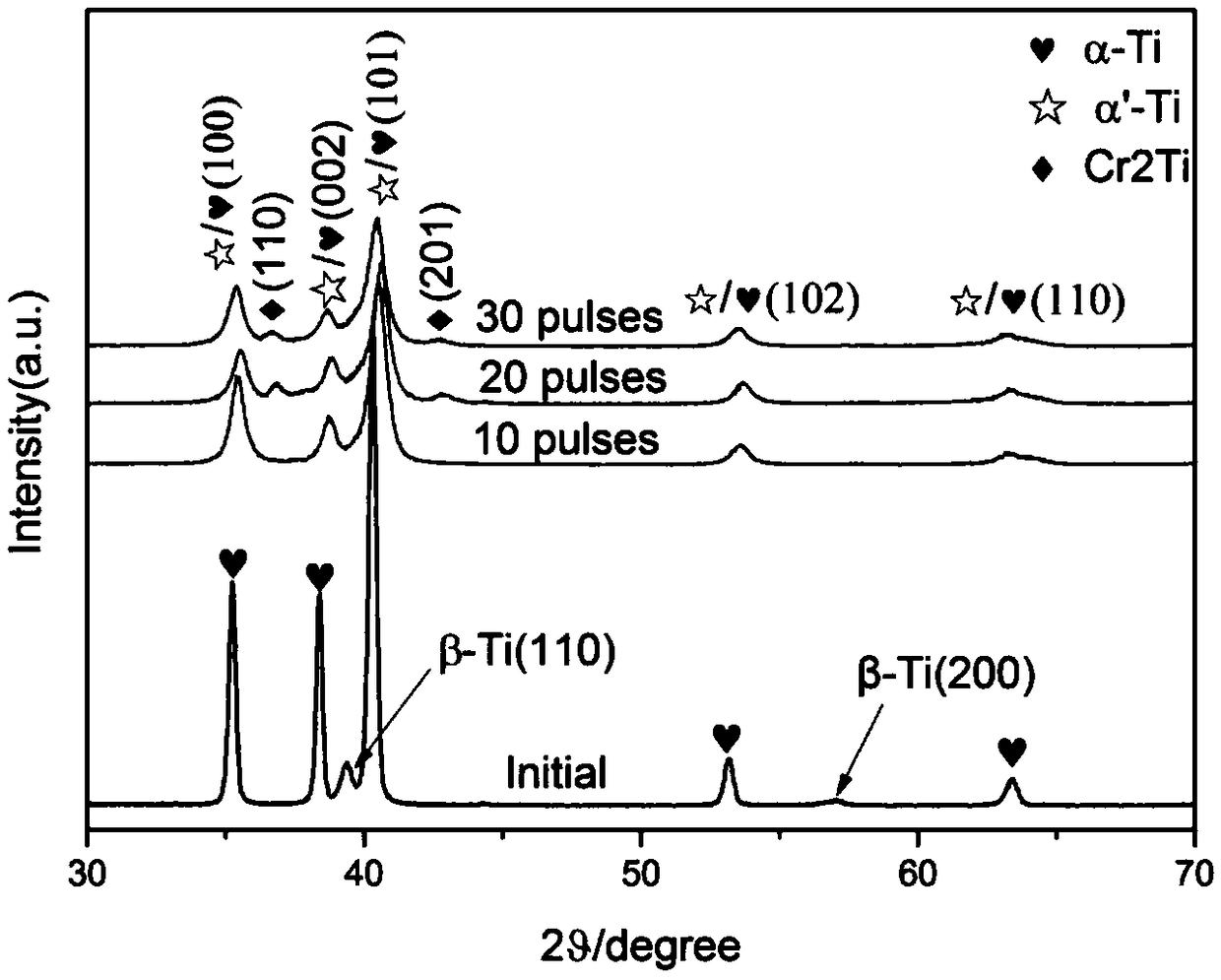

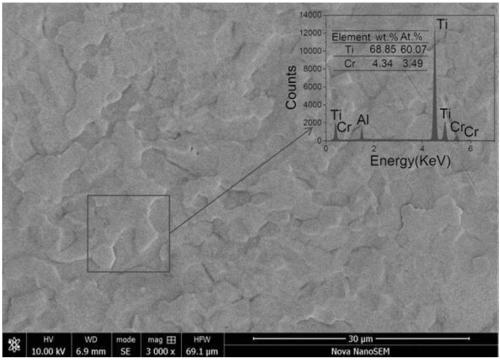

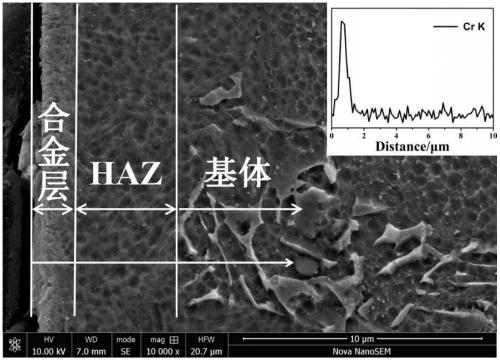

[0033] The third step is to fix the sample with the coating layer facing up, and place it on the "HOPE-1" type pulsed el...

Embodiment 2

[0039] (1) Preparation of alloyed modified layer:

[0040] In the first step, the annealed industrial TC4 titanium alloy bar is selected, and the sample is made into a sample of Φ12×5mm by a wire cutting machine tool.

[0041] The surface of the sample was polished with 150, 400, 800, 1000, 1500, 2000 and 2500 mesh metallographic sandpaper, respectively. Among them, the diamond polishing agent with a particle size of 0.5 μm is selected as the polishing agent, and finally cleaned by ultrasonic cleaning with acetone and absolute ethanol before use.

[0042] In the second step, the Cr powder and the organic binder are mixed uniformly at a ratio of 9g / 100mL to prepare a slurry, and finally the slurry is uniformly coated on the surface of the sample after ultrasonic cleaning to form a coating layer, and the thickness of the coating layer is 78 μm, dry in air.

[0043] The third step is to fix the sample with the coating layer facing up, and place it on the "HOPE-1" type pulsed el...

Embodiment 3

[0049] (1) Preparation of alloyed modified layer:

[0050] In the first step, the annealed industrial TC4 titanium alloy bar is selected, and the sample is made into a sample of Φ12×5mm by a wire cutting machine tool.

[0051] The surface of the sample was polished with 150, 400, 800, 1000, 1500, 2000 and 2500 mesh metallographic sandpaper, respectively. Among them, the diamond polishing agent with a particle size of 0.5 μm is selected as the polishing agent, and finally cleaned by ultrasonic cleaning with acetone and absolute ethanol before use.

[0052] In the second step, the Cr powder and the organic binder are uniformly mixed at a ratio of 9g / 100mL to prepare a slurry, and finally it is uniformly coated on the surface of the sample after ultrasonic cleaning to form a coating layer, and the thickness of the coating layer is 78 μm , placed in the air to dry.

[0053] The third step is to fix the sample with the coating layer facing up, and place it on the "HOPE-1" type pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com