Astaxanthin and sea-buckthorn oil solid beverage and preparation method thereof

A technology for solid drinks and sea buckthorn oil, which is applied in the directions of oil-containing food ingredients, food drying, food ingredients, etc., can solve problems such as unfavorable development and utilization, unstable properties of active substances, and difficulty in dissolving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

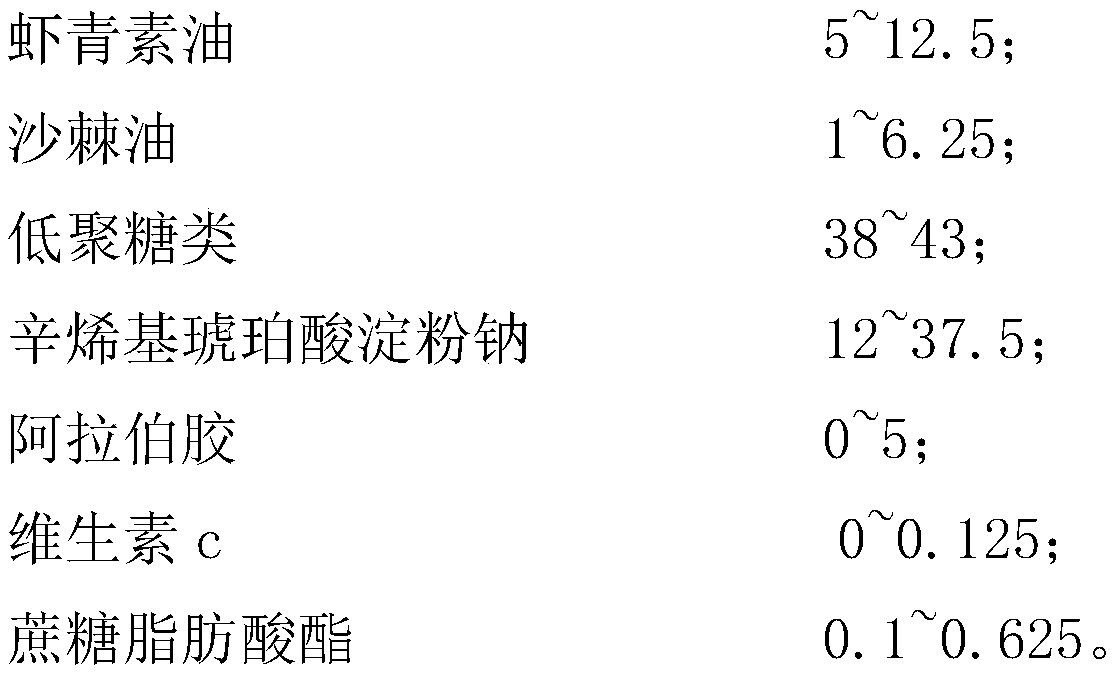

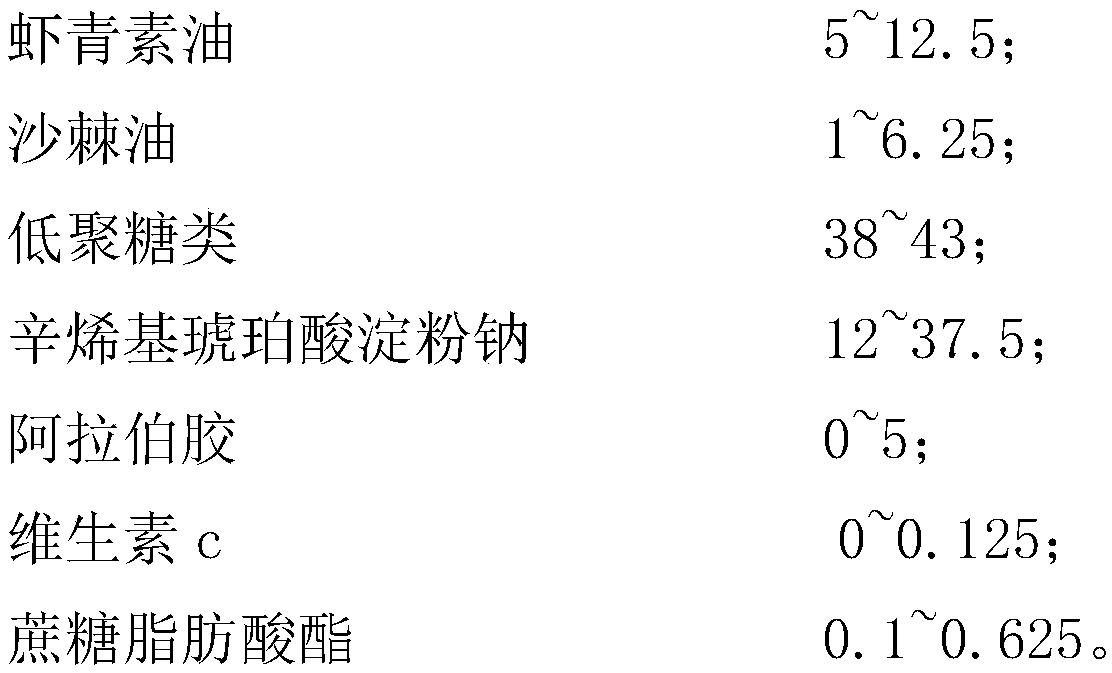

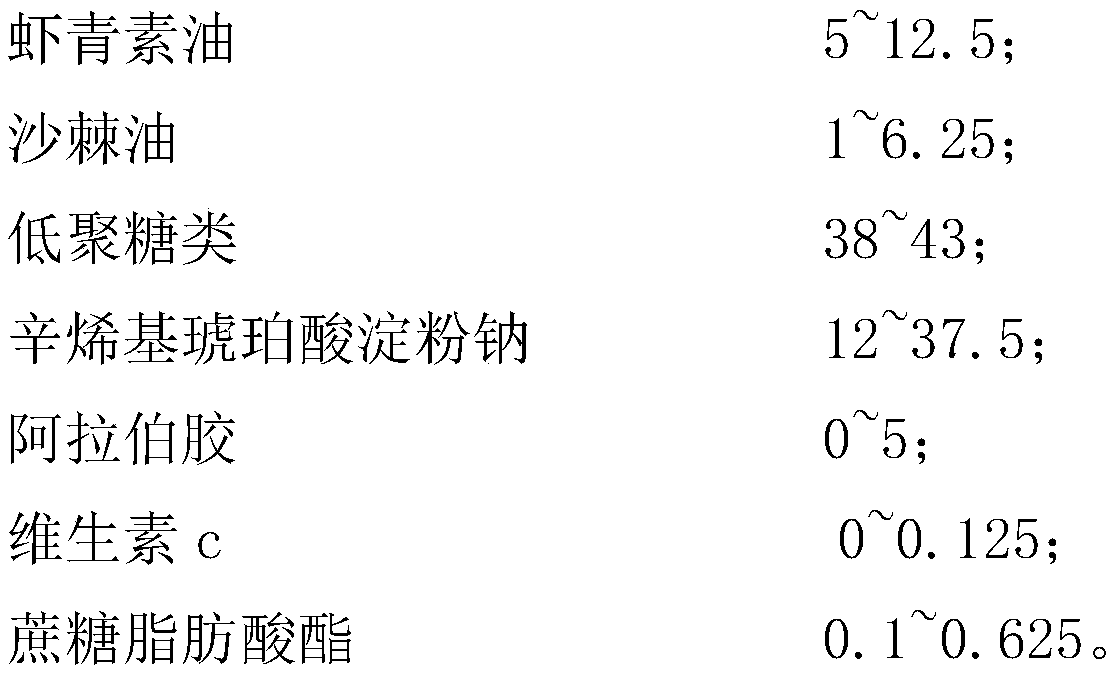

[0042] Astaxanthin oil 1.25kg, sea buckthorn oil 0.625kg, octenyl succinate starch sodium 3.75kg, vitamin c 0.0125kg, sucrose fatty acid ester 0.0625kg, oligoisomaltose 4.3kg

[0043] The preparation method is as follows:

[0044] 1. Put the astaxanthin oil and sea buckthorn oil in the formula into the mixing tank, heat and stir for 1 hour at a temperature of 50-60°C.

[0045] 2. Take the sodium octenyl succinate starch, vitamin c, sucrose fatty acid ester, and isomalt oligosaccharide in the formula and put it into the mixing tank, add 23.3 kg of food-grade drinking water, heat and stir to dissolve for 1 hour, the temperature is 50-60 ℃ .

[0046] 3. After the water phase is completely dissolved, slowly add the oil phase to the water phase with high shear emulsification while adding.

[0047] 4. After the oil phase is added, the material passes through the high-pressure homogenizer twice with a pressure of 40MPa.

[0048] 5. After homogenization, the finished product is obtained by cent...

Embodiment 2

[0050] Astaxanthin oil 1.25kg, sea buckthorn oil 0.625kg, octenyl succinate starch sodium 3.75kg, vitamin c 0.0125kg, sucrose fatty acid ester 0.0625kg, oligoisomaltose 3.8kg, gum arabic 0.5kg

[0051] The preparation method is as follows:

[0052] 1. Put the astaxanthin oil and sea buckthorn oil in the formula into the mixing tank, heat and stir for 1 hour at a temperature of 50-60°C.

[0053] 2. Take the sodium starch octenyl succinate, vitamin c, sucrose fatty acid ester, oligomeric isomaltose, and gum arabic in the formula and put it into the mixing tank, add 23.3 kg of food-grade drinking water, heat and stir to dissolve for 1 hour, temperature 50 ~60℃.

[0054] 3. After the water phase is completely dissolved, slowly add the oil phase to the water phase with high shear emulsification while adding.

[0055] 4. After the oil phase is added, the material passes through the high-pressure homogenizer twice, 40MPa.

[0056] 5. After homogenization, the finished product is obtained by ce...

Embodiment 3

[0058] Astaxanthin oil 1.25 kg, sea buckthorn oil 0.625 kg, starch sodium octenyl succinate 3.75 kg, vitamin c 0.0125 kg, sucrose fatty acid ester 0.0625 kg, maltodextrin 3.8 kg, gum arabic 0.5 kg

[0059] The preparation method is as follows:

[0060] 1. Put the astaxanthin oil and sea buckthorn oil in the formula into the mixing tank, heat and stir for 1 hour at a temperature of 50-60°C.

[0061] 2. Take the sodium starch octenyl succinate, vitamin c, sucrose fatty acid ester, oligomeric isomaltose, and gum arabic in the formula and put it into the mixing tank, add 23.3 kg of food-grade drinking water, heat and stir to dissolve for 1 hour, temperature 50 ~60℃.

[0062] 3. After the water phase is completely dissolved, slowly add the oil phase to the water phase with high shear emulsification while adding.

[0063] 4. After the oil phase is added, the material passes through the high-pressure homogenizer twice with a pressure of 40MPa.

[0064] 5. After homogenization, the finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com