Casting production process and device for boron cast iron cylinder liner

A technology of casting production and cast iron, which is applied in the field of casting production technology and equipment of boron cast iron cylinder liners, which can solve the problems of unsatisfactory degree of graphitization, difficulty in maintaining stable performance of cast iron, and poor shape of graphite, etc., so as to reduce the probability of porosity , reduce the local shrinkage tendency, reduce the effect of local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Add pig iron, ferrochrome, ferromanganese and some scrap steel to the intermediate frequency electric furnace for smelting and slag removal;

[0042] (2) Add ferrophosphorus, ferroboron, copper, silicon carbide and remaining scrap steel to stir and smelt, and take out iron when the sampling test meets the requirements of the original molten iron;

[0043] (3) Add silicon barium and ferrosilicon and stir, remove slag, obtain casting solution;

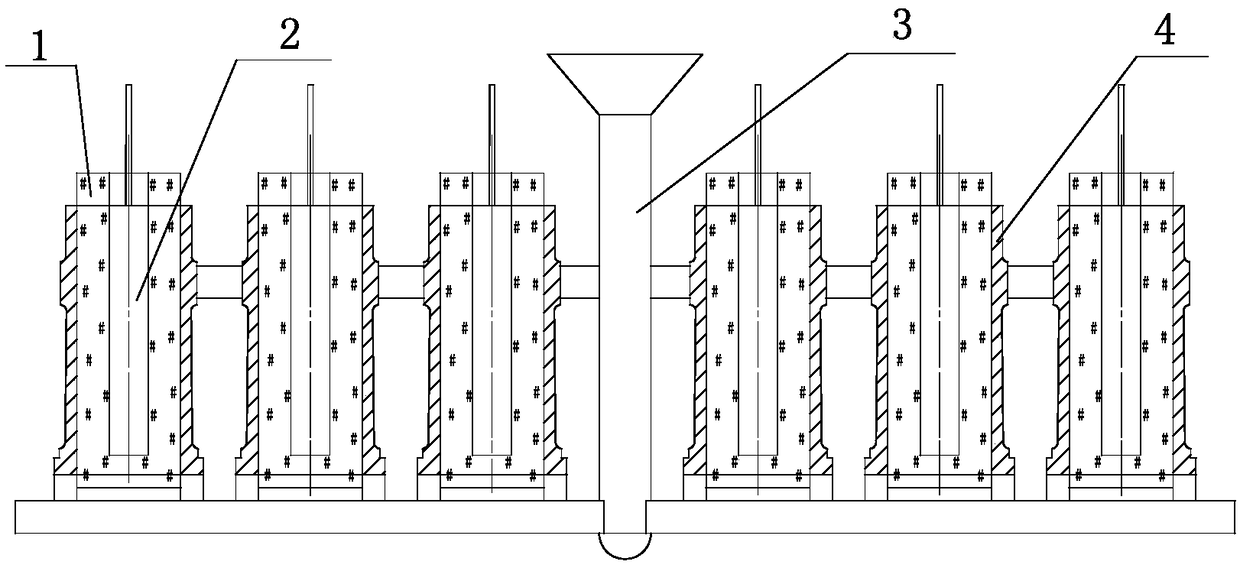

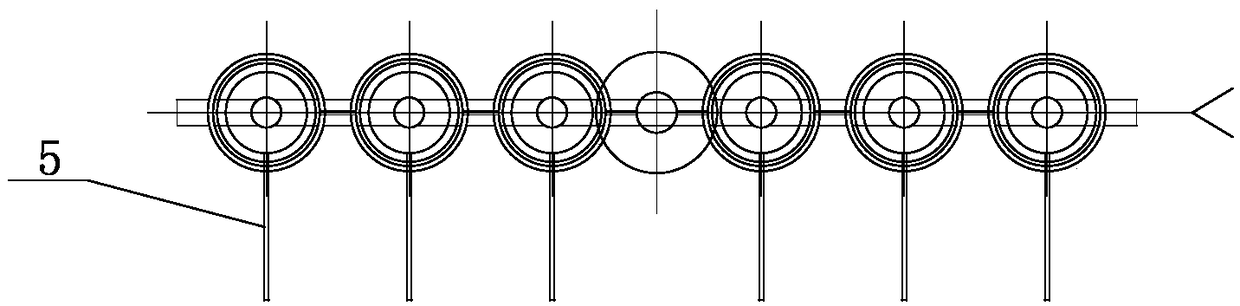

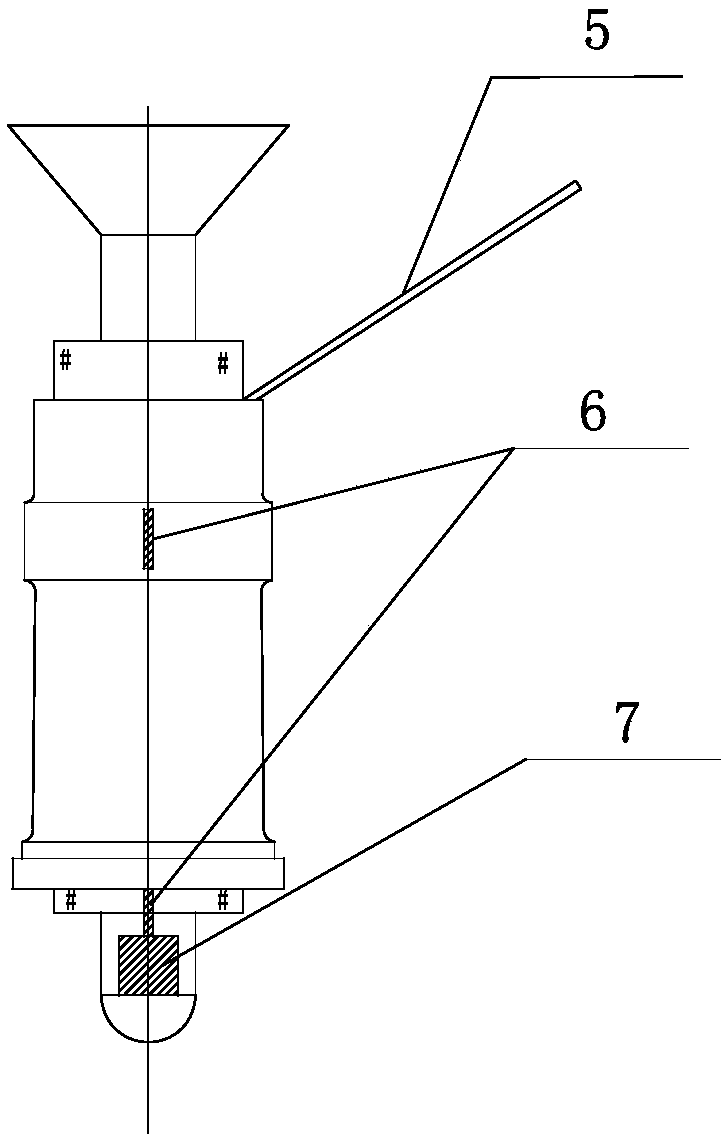

[0044] (4) The molding process adopts furan resin sand to make cores, divides horizontally, and vertically casts a box of 6 pieces with the casting liquid to obtain the product.

[0045] In weight percent,

[0046]

[0047] In step (1), the amount of steel scrap added is 2 / 3 of the total mass of steel scrap.

[0048] The melting temperature in step (1) is 1380°C.

[0049] The original molten iron composition in step (2) is as follows, by weight percentage:

[0050]

[0051]

[0052] The melting temperature in step...

Embodiment 2

[0058] (1) Add pig iron, ferrochrome, ferromanganese and some scrap steel to the intermediate frequency electric furnace for smelting and slag removal;

[0059] (2) Add ferrophosphorus, ferroboron, copper, silicon carbide and remaining scrap steel to stir and smelt, and take out iron when the sampling test meets the requirements of the original molten iron;

[0060] (3) Add silicon barium and ferrosilicon and stir, remove slag, obtain casting liquid;

[0061] (4) The molding process adopts furan resin sand to make cores, divides horizontally, and vertically casts a box of 6 pieces with the casting liquid to obtain the product.

[0062] In weight percent,

[0063]

[0064]

[0065] In step (1), the amount of steel scrap added is 2 / 3 of the total mass of steel scrap.

[0066] The melting temperature in step (1) is 1420°C.

[0067] The original molten iron composition in step (2) is as follows, by weight percentage:

[0068]

[0069] The melting temperature in step (...

Embodiment 3

[0073] (1) Add pig iron, ferrochrome, ferromanganese and some scrap steel to the intermediate frequency electric furnace for smelting and slag removal;

[0074] (2) Add ferrophosphorus, ferroboron, copper, silicon carbide and remaining scrap steel to stir and smelt, and take out iron when the sampling test meets the requirements of the original molten iron;

[0075] (3) Add silicon barium and ferrosilicon and stir, remove slag, obtain casting solution;

[0076] (4) The molding process adopts furan resin sand to make cores, divides horizontally, and vertically casts a box of 6 pieces with the casting liquid to obtain the product.

[0077] In weight percent,

[0078]

[0079]

[0080] In step (1), the amount of steel scrap added is 2 / 3 of the total mass of steel scrap.

[0081] The melting temperature in step (1) is 1390°C.

[0082] The original molten iron composition in step (2) is as follows, by weight percentage:

[0083]

[0084] The melting temperature in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com