Method for treating sulfolane wastewater

A technology for wastewater treatment and sulfolane, which is applied in extraction water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of simple process flow, low equipment investment and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

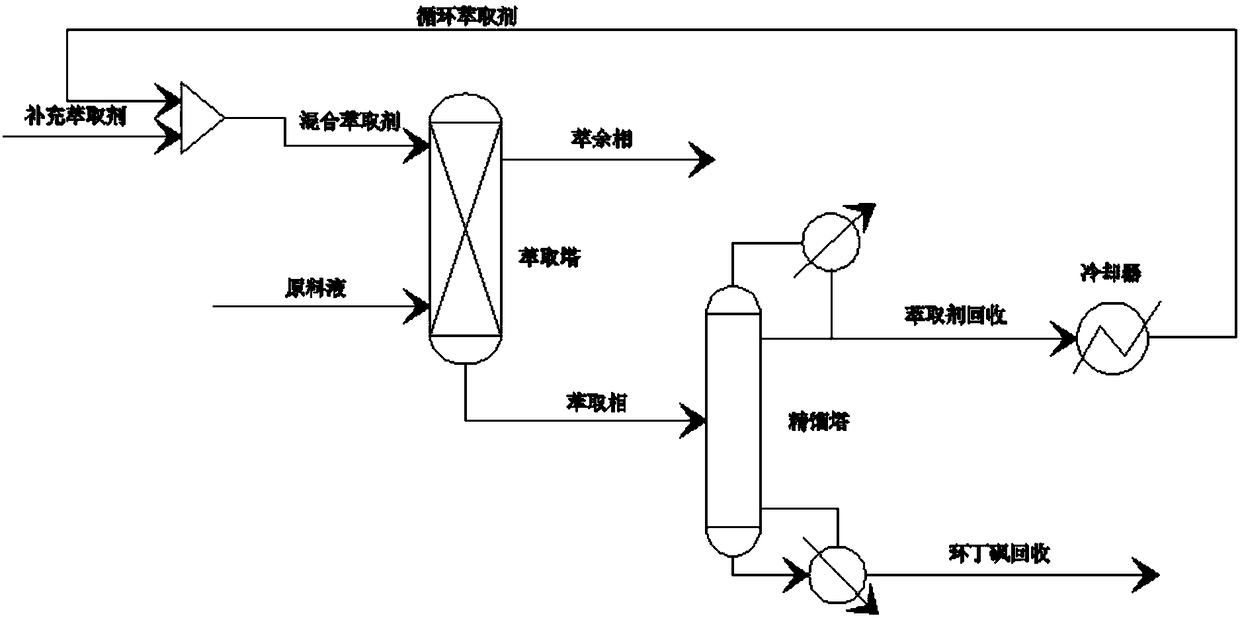

Image

Examples

Embodiment 1

[0022] A set of treatment equipment with a treatment capacity of 100t / h waste water, the content of sulfolane is 100g / L, the method of the present invention is adopted, the extraction agent is dichloromethane, and the extraction equipment is an extraction tower. The waste water and the extractant are pumped into the extraction tower from the bottom and the top of the extraction tower respectively for countercurrent extraction to obtain the extract phase and the raffinate phase, and then the extractant and sulfolane in the extract phase are recovered through the rectification process. The recovered extractant is recycled after cooling. The extraction temperature is 15°C, the volume ratio of extractant to waste water is 1:2, and the theoretical extraction stages are 15. The theoretical stages of the rectification column are 3, the reflux ratio is 0.10, the operating temperature at the top of the tower is 32°C, and the operating temperature at the bottom of the tower is 167°C.

...

Embodiment 2

[0025] A set of treatment equipment with a treatment capacity of 100t / h waste water, the content of sulfolane is 100g / L, the method of the present invention is adopted, and the extractant is a mixture of dichloromethane and chloroform. The mixing ratio is dichloromethane:chloroform=1:4, and the extraction equipment is an extraction tower. The waste water and the extractant are pumped into the extraction tower from the bottom and the top of the extraction tower respectively for countercurrent extraction to obtain the extract phase and the raffinate phase, and then the extractant and sulfolane in the extract phase are recovered through the rectification process. The recovered extractant is recycled after cooling. The extraction temperature is 25°C, the volume ratio of extractant to waste water is 1:2, and the theoretical extraction stages are 4. The theoretical stage of the rectification tower is 6, the reflux ratio is 0.49, the operating temperature at the top of the tower is ...

Embodiment 3

[0028] A set of treatment equipment with a treatment capacity of 100t / h waste water, the content of sulfolane is 100g / L, the method of the present invention is adopted, the extraction agent is ethyl acetate, and the extraction equipment is an extraction tower. The waste water and the extractant are pumped into the extraction tower from the bottom and the top of the extraction tower respectively for countercurrent extraction to obtain the extract phase and the raffinate phase, and then the extractant and sulfolane in the extract phase are recovered through the rectification process. The recovered extractant is recycled after cooling. The extraction temperature is 40°C, the volume ratio of extractant to waste water is 1:1, and the theoretical extraction stages are 14. The theoretical stages of the rectification tower are 5, the reflux ratio is 0.15, the operating temperature at the top of the tower is 65°C, and the operating temperature at the bottom of the tower is 255°C.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com