Fluorescent color changing eutectic material under ultrahigh pressure conditions and preparation method thereof

A eutectic material, ultra-high pressure technology, applied in the direction of color-changing fluorescent materials, organic chemistry methods, chemical instruments and methods, etc., can solve the problem of unpredictable fluorescence color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Weigh 0.0664g of 1,4-bis(1-cyano-2-phenylethenyl)benzene and 0.1821g of 2,3,5,6-tetrafluorohydroquinone;

[0034] 2. Mix the two evenly, put them in the MM200 ball mill, add 3 drops of chloroform with a dropper, then put them into the ball mill, and ball mill at 20Hz for 20 minutes;

[0035] 3. Take about 0.1g of the ground powder and dissolve it in 10mL of chloroform, place it at room temperature, and wait for the solvent to evaporate slowly to obtain a binary eutectic single crystal product;

[0036] To characterize the product,

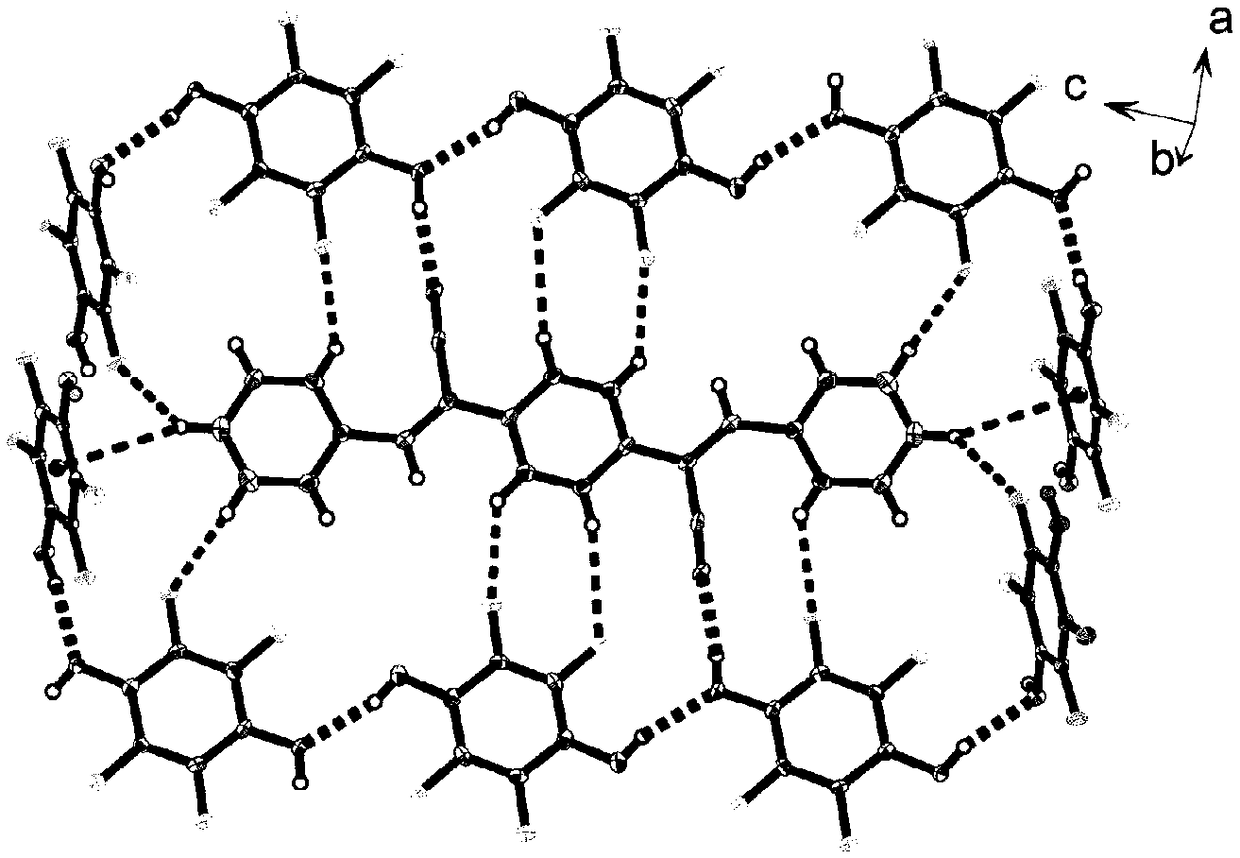

[0037]According to the single crystal X-ray diffraction analysis, the cyano-substituted p-phenylene vinylene and 2,3,5,6-tetrafluorohydroquinone form a two-component with a double ring structure through intermolecular multiple hydrogen bond interactions Co-crystal products such as figure 1 shown.

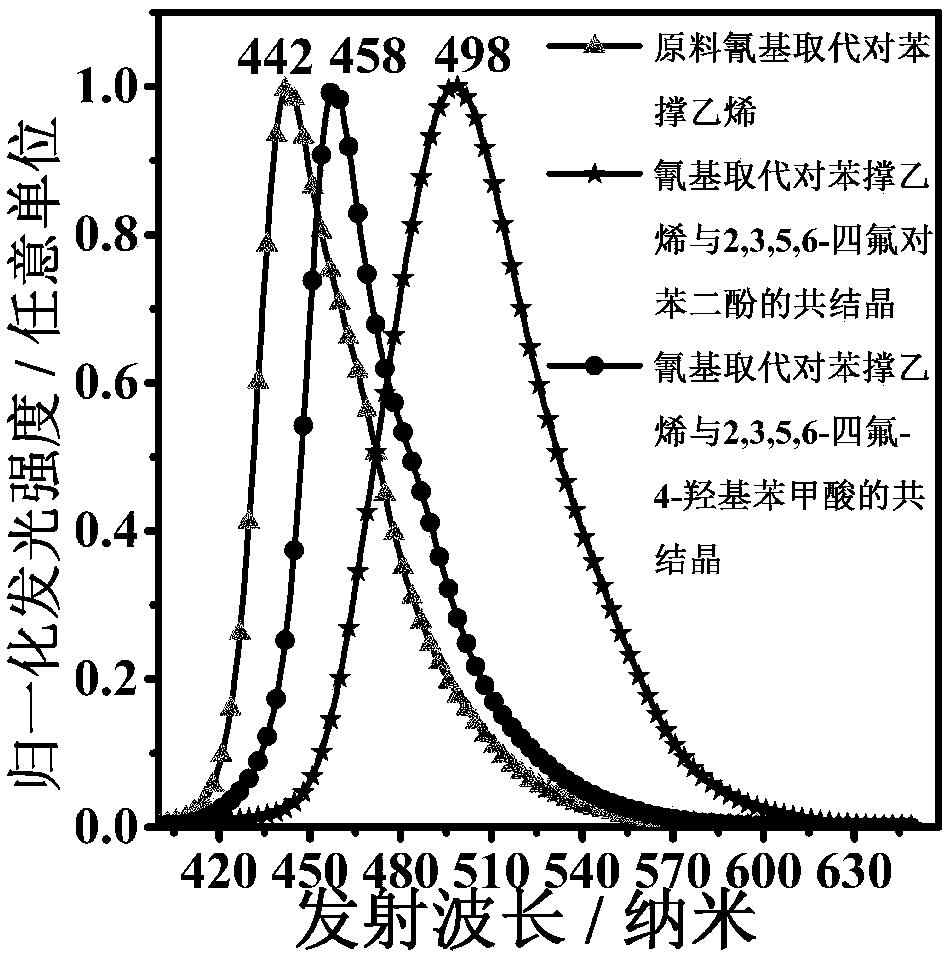

[0038] It can be seen from the fluorescence spectrum that the maximum emission of the new co-crystal material is at about 498nm, and it sho...

Embodiment 2

[0041] 1. Weigh 0.0332g of 1,4-bis(1-cyano-2-phenylethenyl)benzene and 0.0420g of 2,3,5,6-tetrafluoro-4-hydroxybenzoic acid, dissolve in 6mL Chloroform solvent, using ultrasonic or heating means to make it dissolve as much as possible, at this time, the liquid gradually turns into a light blue-green turbid liquid;

[0042] 2. Add methanol solvent to the light blue-green turbid liquid drop by drop until the solution is clear and transparent. The volume of methanol added is about 0.5-1mL, and then continue to sonicate or heat to make the solution evenly mixed and the solute fully dissolved;

[0043] 3. After standing for 1-2 weeks under natural volatilization conditions, the eutectic compound of cyano-substituted p-phenylene vinylene and 2,3,5,6-tetrafluoro-4-hydroxybenzoic acid can be obtained;

[0044] To characterize the product,

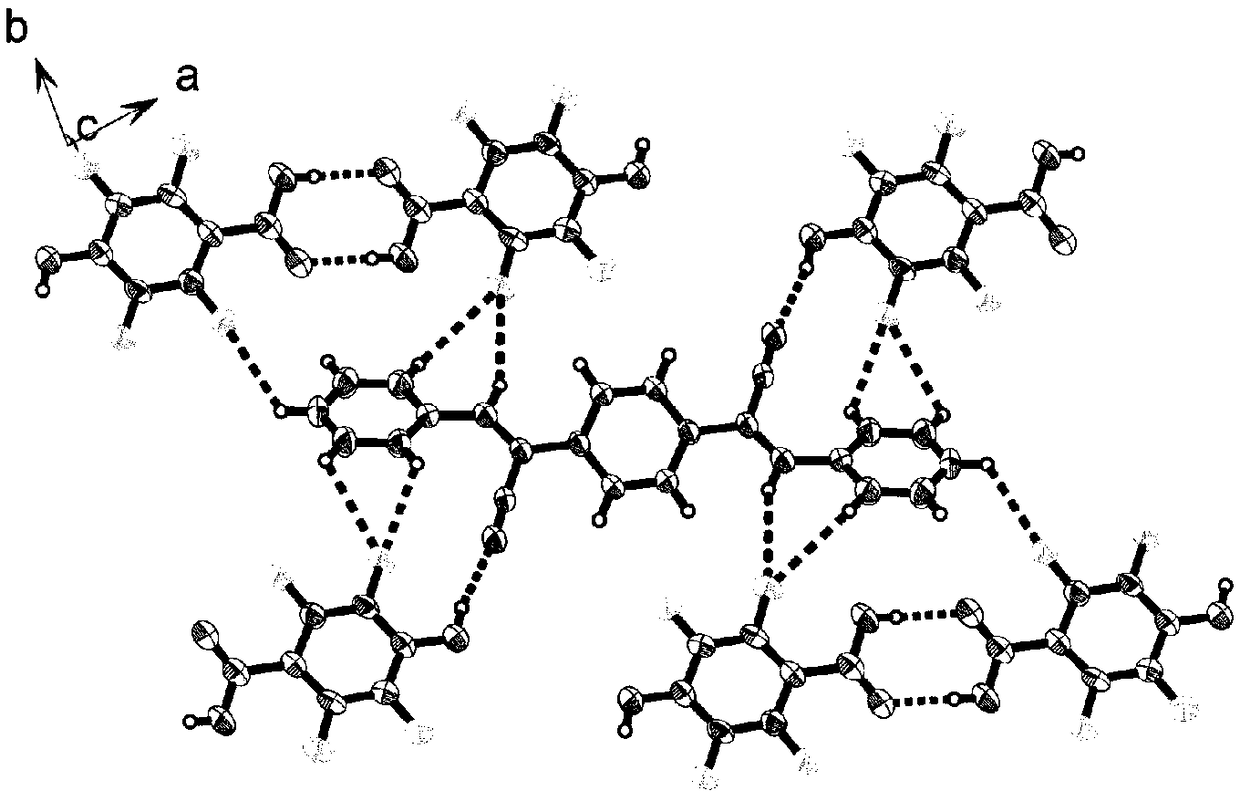

[0045] According to the analysis of single crystal X-ray diffraction, the cyano-substituted p-phenylene vinylene and 2,3,5,6-tetrafluoro-4-hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com