Method for preparing propionate by means of microreactor

A technology of micro-reactor and propionate, which is applied in the direction of chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., can solve the problems of three wastes in the reaction process, serious corrosion, long reaction time, etc., and achieve shortening The effect of high production cycle, high conversion rate and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Reaction raw materials: 74 g (1 mol) of propionic acid, 38.4 g (1.2 mol) of methanol, 0.22 g of bisfluorosulfonimide imidazolium salt as an acidic ionic liquid catalyst (accounting for 0.2% of the total mass of the reaction raw materials).

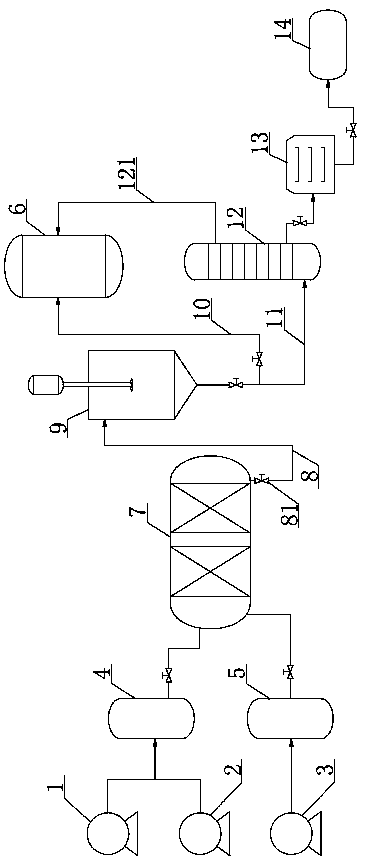

[0024] Propionic acid and methanol are pumped into the first blender 4 through the first metering pump 1 and the second metering pump 2 respectively, and bisfluorosulfonimide imidazolium salt is pumped into the second blender 5 through the third metering pump 3 middle. The liquid in the first blender 4 and the second blender 5 enters the microreactor 7, and reacts at a temperature of 50° C. for 10 minutes. Sampling and monitoring is carried out from the sampling end of the sampling stop valve 81. The alcohol content is 0.02%, and the reaction is determined. Finish. Open the sampling shut-off valve 81, the material in the microreactor 7 enters in the filter 9 through the material output pipe 8, separates the water layer and the orga...

Embodiment 2

[0026] Reaction raw materials: 74g (1mol) of propionic acid, 69.10g (1.5mol) of ethanol, 0.36g of bisfluorosulfonimide imidazolium salt as an acidic ionic liquid catalyst (accounting for 0.25% of the total mass of the reaction raw materials).

[0027]Propionic acid and ethanol are pumped into the first blender 4 through the first metering pump 1 and the second metering pump 2 respectively, and bisfluorosulfonimide imidazolium salt is pumped into the second blender 5 through the third metering pump 3 middle. The liquid in the first blender 4 and the second blender 5 enters the microreactor 7, and the temperature is controlled at 60°C to react for 40 minutes, and the sample is monitored from the sampling end of the sampling stop valve 81. The alcohol content is 0.04%, and the reaction is determined. Finish. Open the sampling shut-off valve 81, the material in the microreactor 7 enters in the filter 9 through the material output pipe 8, separates the water layer and the organic ...

Embodiment 3

[0029] Reaction raw materials: 74g (1mol) of propionic acid, 78g (1.3mol) of propanol, 0.46g of bisfluorosulfonimide imidazolium salt as an acidic ionic liquid catalyst (accounting for 0.3% of the total mass of the reaction raw materials).

[0030] Propionic acid and propanol are pumped into the first blender 4 through the first metering pump 1 and the second metering pump 2 respectively, and bisfluorosulfonimide imidazolium salt is pumped into the second blender through the third metering pump 3 5 in. The liquid in the first blender 4 and the second blender 5 enters the microreactor 7, and reacts at a temperature of 55°C for 60 minutes. Sampling and monitoring is carried out from the sampling end of the sampling stop valve 81. The alcohol content is 0.03%, and the reaction is determined. Finish. Open the sampling shut-off valve 81, the material in the microreactor 7 enters in the filter 9 through the material output pipe 8, separates the water layer and the organic layer in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com