Radiation cross-linked polypropylene foaming material, preparation method and applications thereof

A technology of radiation crosslinking and foaming materials, which is applied in the field of radiation crosslinking polypropylene foaming materials, which can solve the problem of uneven cell structure of polypropylene foaming materials, difficult operation of the foaming process, and small physical foaming temperature window And other problems, to achieve the effect of improving melt strength and foaming performance, good sound insulation and noise reduction effect, and high thermal deformation load temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

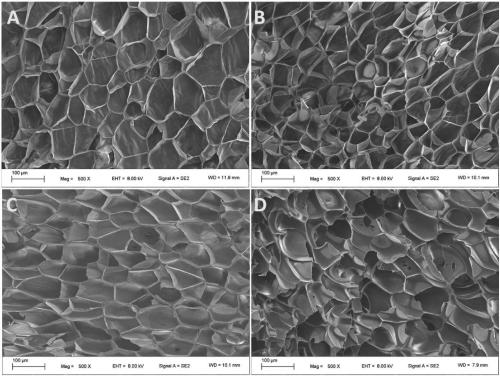

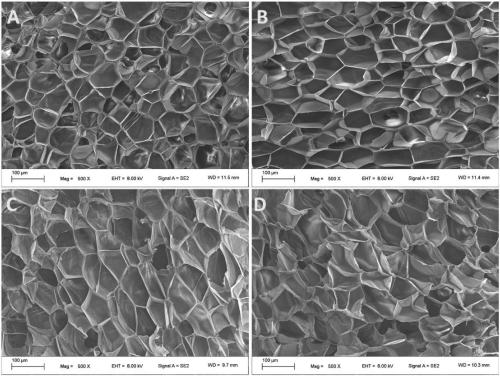

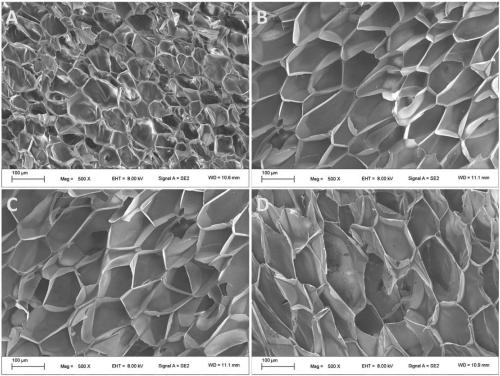

[0049] 90 parts of conventional polypropylene with a melt index of 3.0g / 10min and 10 parts of high-density polyethylene particles with a melt index of 1.0g / 10min were mixed by twin-screw at 190°C, and the mixture was placed in a vulcanization molding machine for compression The sheet is finalized, taken out after molding, and placed in the environment to cool naturally to obtain a mixture sheet;

[0050] Put the mixture sheet into an irradiation tank with a nitrogen atmosphere and seal it, place it in a cobalt source for irradiation, and the absorbed dose is 30kGy, then take out the irradiation tank, and store the mixture sheet in a nitrogen atmosphere; Before foaming, take it out, cut it into a sheet of suitable size for foaming, place it in a high-pressure reactor, exhaust the air, inject supercritical carbon dioxide, pressurize it to 20MPa, seal it, and heat it up to 150°C , keep warm for 1.5h, and release the pressure. The average pressure release rate is 5MPa / s.

Embodiment 2

[0052] Absorbed dose is 60kGy, all the other are the same as embodiment 1.

Embodiment 3

[0054] The absorbed dose is 90kGy, and all the other are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com