Method for preparing waterproof conductive paint

A conductive coating and mixing technology, which is applied in the direction of conductive coatings, anti-corrosion coatings, fire-proof coatings, etc., can solve the problems of poor salt corrosion resistance, etc., and achieve the effects of stable conductivity, good compatibility, and a wide range of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment relates to a waterproof conductive coating and a preparation method thereof, the coating is composed of the following raw materials in parts by weight:

[0053] 46 parts of acrylic resin;

[0054] 20 parts of dammar resin;

[0055] Gallium arsenide 2 parts;

[0056] 6.5 parts of dead sea mud;

[0057] 4 parts perovskite powder;

[0058] 1 part of cellulose acetate butyrate;

[0059] 1.5 parts of brucite chopped fibers;

[0060] 0.3 parts of diethylene glycol dibenzoate;

[0061] 9 parts of dimethyl sulfoxide;

[0062] 3 parts snail slime;

[0063] Accelerator 0.65 parts;

[0064] 0.95 parts of crosslinking agent;

[0065] 0.5 parts of coupling agent;

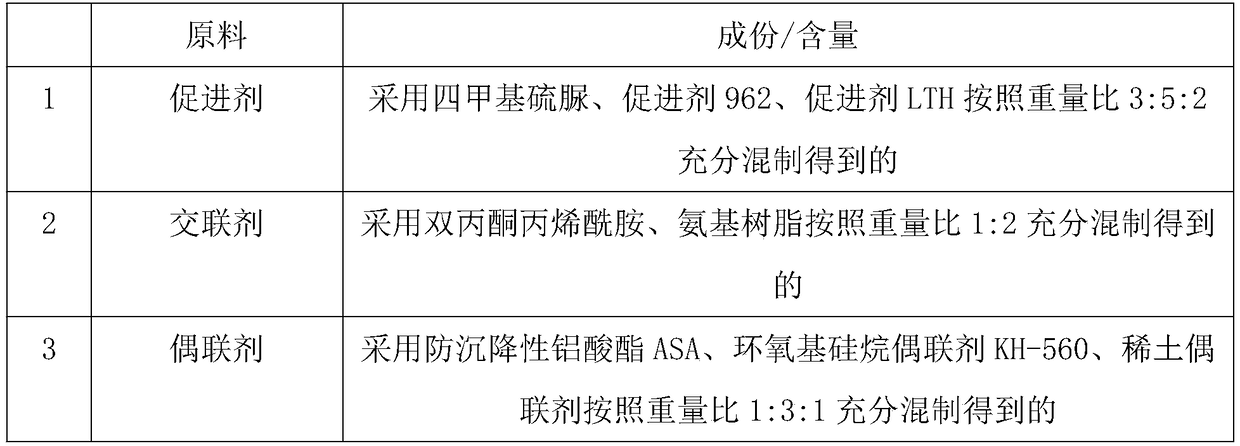

[0066] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 1 below:

[0067] Table 1

[0068]

[0069] The preparation method of present embodiment coating is carried out according to the following steps:

[0070]...

Embodiment 2

[0075] This embodiment relates to a waterproof conductive coating and a preparation method thereof, the coating is composed of the following raw materials in parts by weight:

[0076] 48 parts of acrylic resin;

[0077] 21 parts of dammar resin;

[0078] Gallium arsenide 2.4 parts;

[0079] 7 parts dead sea mud;

[0080] 4.5 parts of perovskite powder;

[0081] 1.2 parts of cellulose acetate butyrate;

[0082] 1.8 parts of brucite chopped fibers;

[0083] 0.35 parts of diethylene glycol dibenzoate;

[0084] 10 parts of dimethyl sulfoxide;

[0085] 3.5 parts of snail mucus;

[0086] Accelerator 0.7 part;

[0087] 1.05 parts of crosslinking agent;

[0088] 0.55 parts of coupling agent;

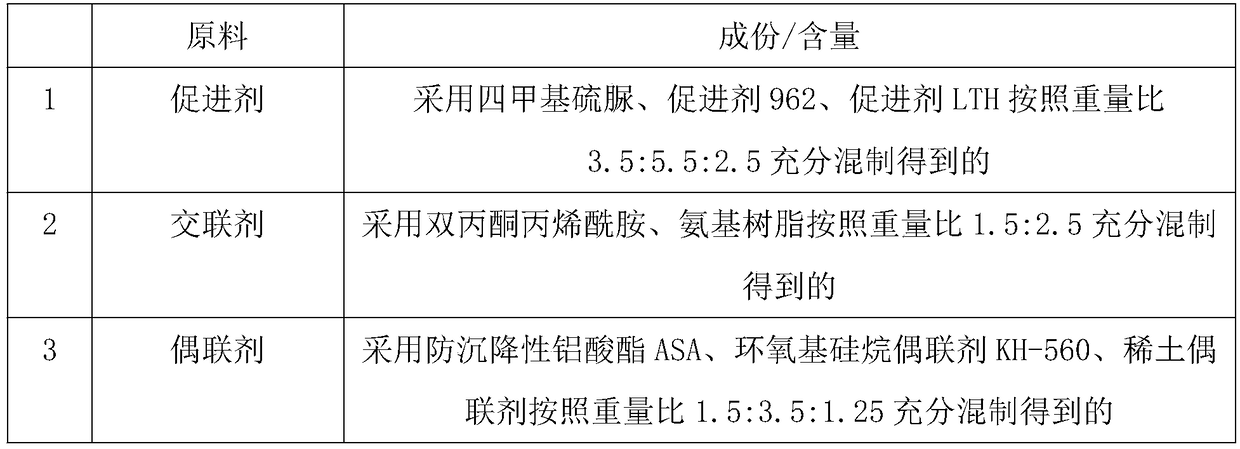

[0089] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 2 below:

[0090] Table 2

[0091]

[0092] The preparation method of present embodiment coating is carried out according to the following steps...

Embodiment 3

[0098] This embodiment relates to a waterproof conductive coating and a preparation method thereof, the coating is composed of the following raw materials in parts by weight:

[0099] 49 parts of acrylic resin;

[0100] 22 parts of dammar resin;

[0101] Gallium arsenide 2.7 parts;

[0102] 7.5 parts of dead sea mud;

[0103] 5 parts perovskite powder;

[0104] 1.5 parts of cellulose acetate butyrate;

[0105] 2 parts of brucite chopped fiber;

[0106] 0.4 parts of diethylene glycol dibenzoate;

[0107] 11 parts of dimethyl sulfoxide;

[0108] 4 parts snail slime;

[0109] Accelerator 0.75 parts;

[0110] 0.15 parts of crosslinking agent;

[0111] 0.6 parts of coupling agent;

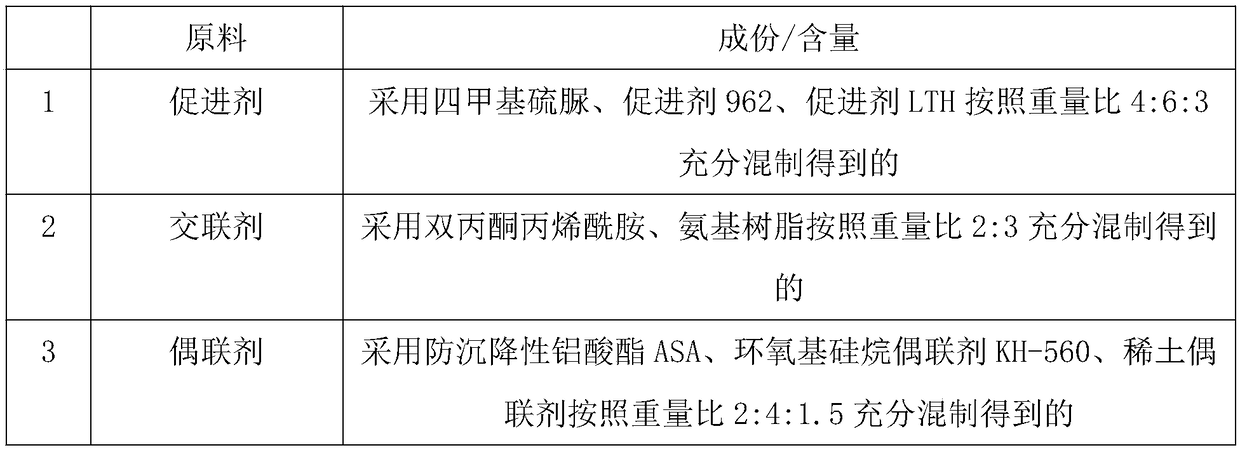

[0112] The selection and preparation of promotor, cross-linking agent and coupling agent in the present embodiment are shown in Table 3 below:

[0113] table 3

[0114]

[0115] The preparation method of present embodiment coating is carried out according to the following steps:

[0116]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com