Preparation method of suspension proppant

A proppant, self-suspension technology, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of environmental pollution, cost increase, etc., achieve short process time, low equipment and energy consumption, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

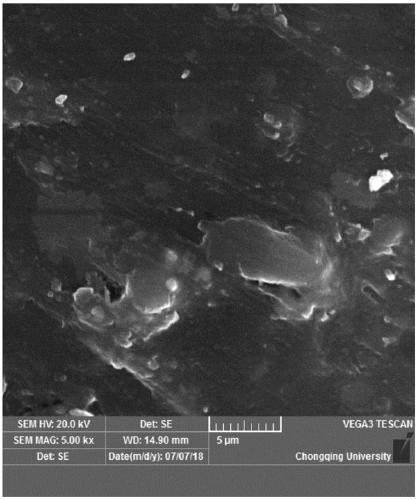

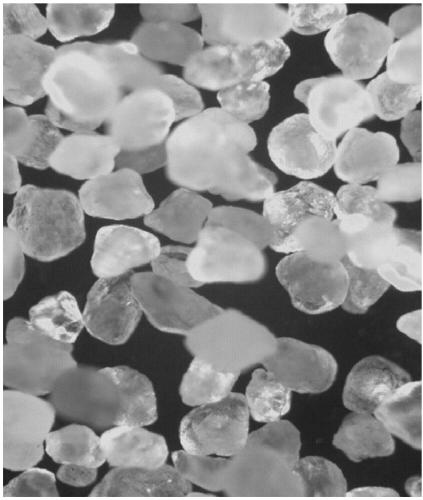

Image

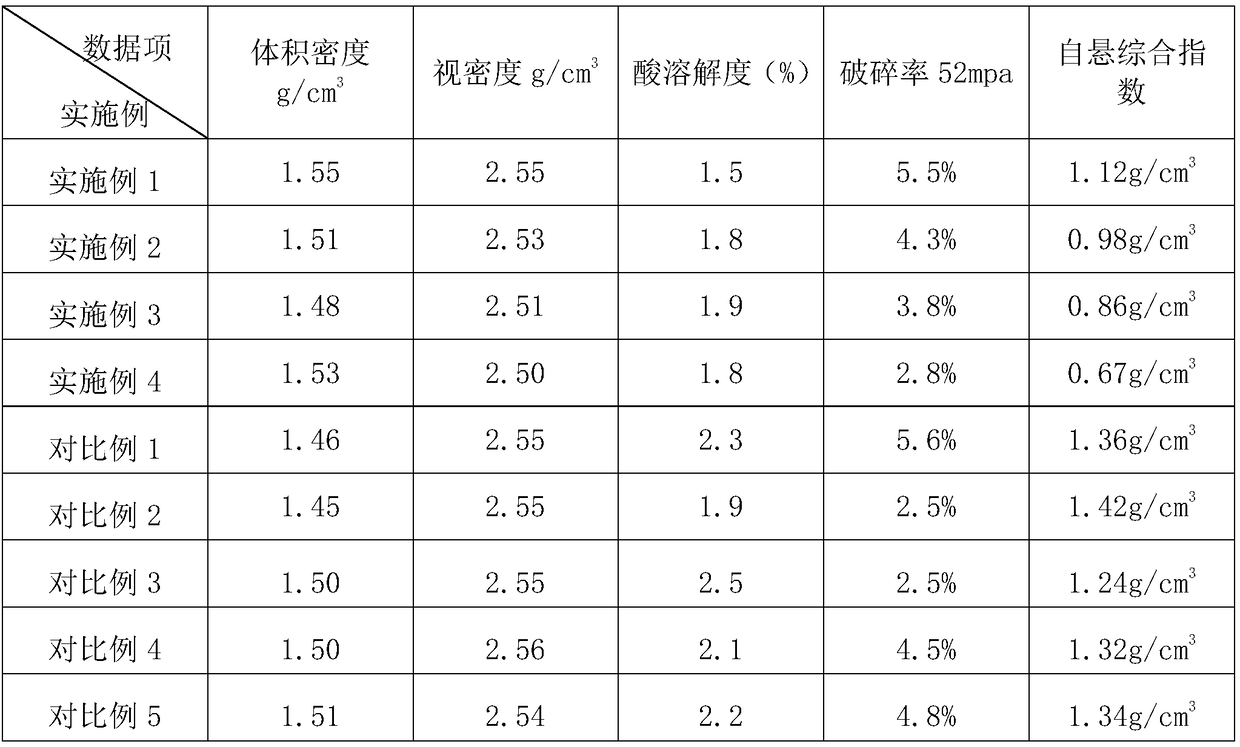

Examples

Embodiment 1

[0044] Take 100 parts of quartz sand with a particle size of 20 / 40, heat it to 180°C, pour the heated quartz sand into a bowl-shaped mixing casserole, add 0.5 parts of epoxy resin, 0.05 parts and 0.1 curing agent T31 and stir until the temperature reaches 160 After -170°C, add 5 parts of propylene glycol polymer and 0.05 parts of dibutyltin dilaurate and stir, and when the temperature reaches 140-150°C, add 0.005 parts of a mixture of diethylenetriamine and ethylenediamine and stir until the temperature reaches 100-120 ℃, add 3.5 parts of toluene diisocyanate and stir, and take out of the pot after the temperature reaches 80 ℃.

Embodiment 2

[0046] Take 100 parts of quartz sand with a particle size of 30 / 50, heat it to 230°C, pour the heated quartz sand into a bowl-shaped mixing casserole, add 5 parts of phenolic resin and 1.5 parts of hexamethylenetetramine and stir until the temperature reaches 190 After -200°C, add 3 parts of ethylene glycol polymer and 0.003 parts of dibutyltin dilaurate and stir, and when the temperature reaches 160-170°C, add 0.45 parts of a mixture of triethylamine and triethylenetetramine and stir until the temperature reaches 140 After -150°C, add 2.1 parts of methylene diphenyl diisocyanate and stir, and take out of the pot after the temperature reaches 90°C.

Embodiment 3

[0048] Take 100 parts of quartz sand with a particle size of 40 / 70, heat it to 190°C, pour the heated quartz sand into a bowl-shaped mixing casserole, add 6 parts of epoxy ester resin and 2.5 parts of curing agent 31 and stir until the temperature reaches 160- After 170℃, add 2 parts of ethylene glycol polymer and 0.02 parts of dibutyltin dilaurate and stir. After the temperature reaches 140-150℃, add 0.2 parts of ethylamine and stir. After the temperature reaches 110-120℃, add 1.4 parts of isofor Stir with ketone diisocyanate, and take it out of the pot after the temperature reaches 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com