Composite cleaning liquid for chemiluminescent instrument pipeline and preparation method thereof

A chemiluminescent instrument and cleaning solution technology, which is applied in the field of immunity, can solve the problems of reduced cleaning solution effect, affecting the cleaning effect, and long-term storage of reagents, and achieves the effect of being suitable for long-term storage, simple preparation method, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

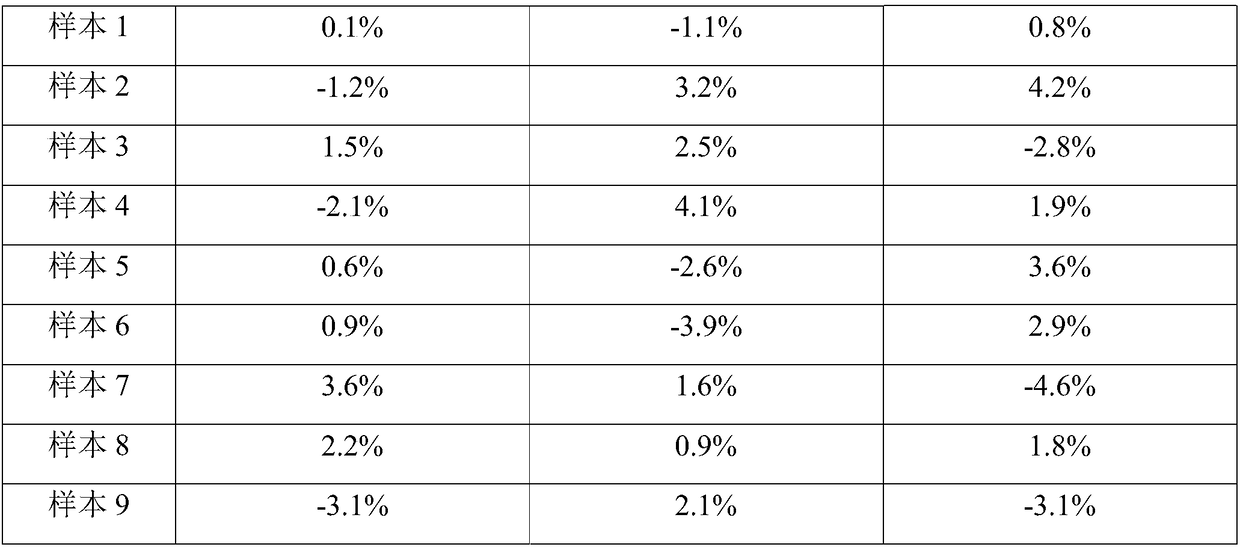

Embodiment 1

[0019] A composite cleaning solution for chemiluminescent instrument pipelines, which is composed of the following components in proportions by weight: 51 parts of di-sodium hydrogen phosphate, 38 parts of potassium dihydrogen phosphate, 17 parts of zinc chloride, sodium lauryl sulfate 22 parts, 7 parts of glycerin, 0.6 parts of potassium hydrogen phthalate, 0.2 parts of sodium hydroxide, 0.7 parts of gentamicin, 51 parts of 2-morpholineethanesulfonic acid, 37 parts of dipotassium hydrogen phosphate, citric acid 21 parts, polyethylene glycol 21 parts, bovine serum albumin 6 parts, sucrose 16 parts, Tween-20 0.7 parts, Proclin 300 0.6 parts, deionized water 380 parts.

[0020] A method for preparing a composite cleaning solution for pipelines of chemiluminescent instruments, comprising the following steps:

[0021] Step 1. Heat deionized water to 40°C, add dibasic sodium phosphate, potassium dihydrogen phosphate, zinc chloride, and sodium lauryl sulfate in sequence, stir at a s...

Embodiment 2

[0028] A compound cleaning solution for pipelines of chemiluminescent instruments, which is composed of the following components in proportions by weight: 55 parts of di-sodium hydrogen phosphate, 50 parts of potassium dihydrogen phosphate, 15 parts of zinc chloride, sodium lauryl sulfate 25 parts, 7 parts of glycerin, 0.6 parts of potassium hydrogen phthalate, 0.3 parts of sodium hydroxide, 0.7 parts of gentamicin, 55 parts of 2-morpholineethanesulfonic acid, 35 parts of dipotassium hydrogen phosphate, citric acid 25 parts, polyethylene glycol 20 parts, bovine serum albumin 5 parts, sucrose 16 parts, Tween-20 0.7 parts, Proclin 300 0.6 parts, deionized water 400 parts.

[0029] A method for preparing a composite cleaning solution for pipelines of chemiluminescent instruments, comprising the following steps:

[0030] Step 1. Heat the deionized water to 38°C, add dibasic sodium phosphate, potassium dihydrogen phosphate, zinc chloride, and sodium lauryl sulfate in sequence, stir...

Embodiment 3

[0037] A composite cleaning solution for chemiluminescent instrument pipelines, which is composed of the following components in proportions by weight: 56 parts of dibasic sodium phosphate, 38 parts of potassium dihydrogen phosphate, 16 parts of zinc chloride, sodium lauryl sulfate 22 parts, 8 parts of glycerin, 0.6 parts of potassium hydrogen phthalate, 0.3 parts of sodium hydroxide, 0.9 parts of gentamicin, 51 parts of 2-morpholineethanesulfonic acid, 39 parts of dipotassium hydrogen phosphate, citric acid 22 parts, polyethylene glycol 23 parts, bovine serum albumin 6 parts, sucrose 19 parts, Tween-20 0.7 parts, Proclin 300 0.8 parts, deionized water 420 parts.

[0038] A method for preparing a composite cleaning solution for pipelines of chemiluminescent instruments, comprising the following steps:

[0039] Step 1. Heat the deionized water to 39°C, add dibasic sodium phosphate, potassium dihydrogen phosphate, zinc chloride, and sodium lauryl sulfate in sequence, stir at a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com