Graphene reinforced titanium-based composite material characterized by three-dimensional network-shaped distribution, preparation method thereof and application thereof

A titanium-based composite material and three-dimensional network technology, which is applied in the field of metal-based composite materials, can solve the problems of difficult network distribution, increase of titanium oxygen content, material quality decline, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

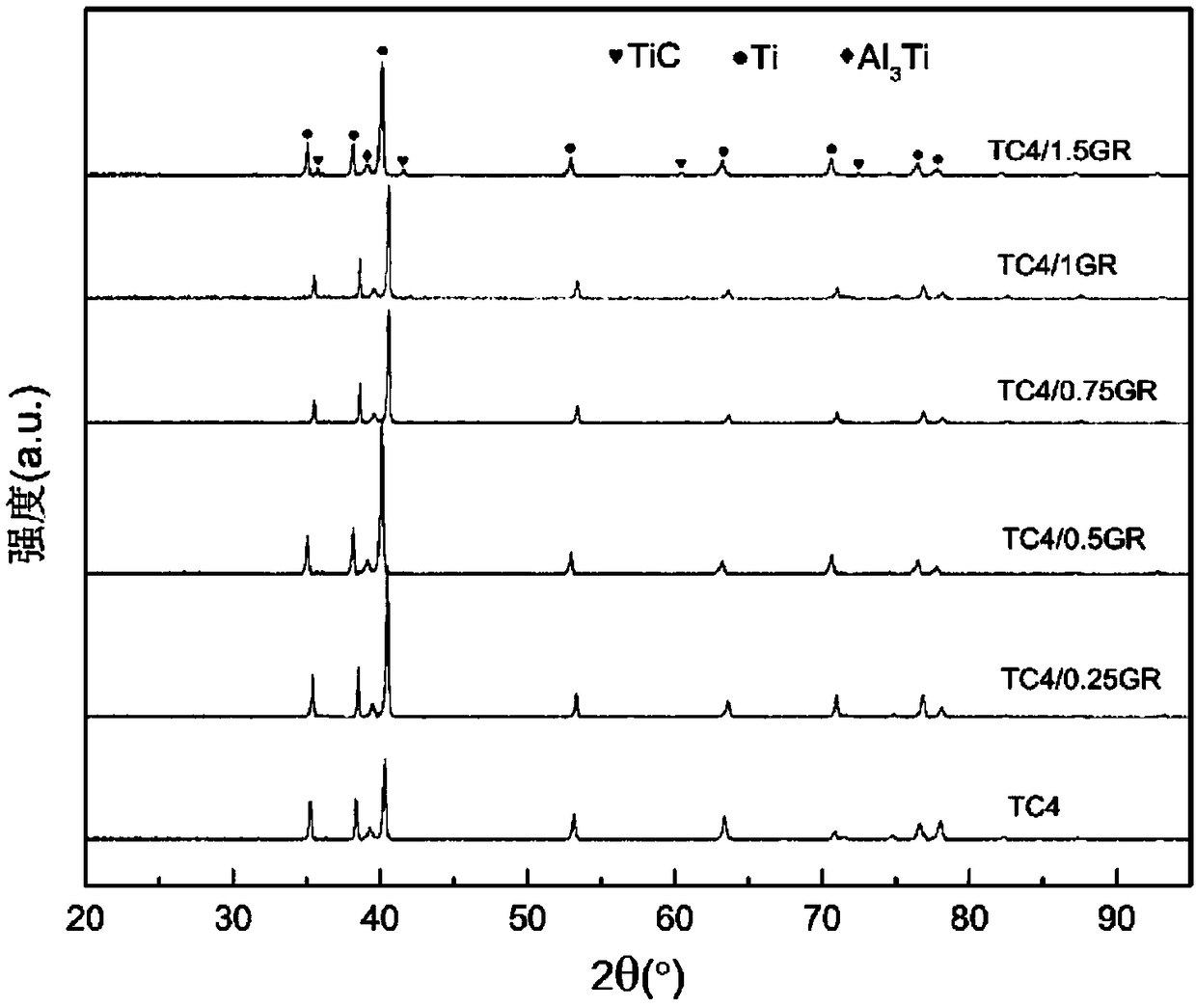

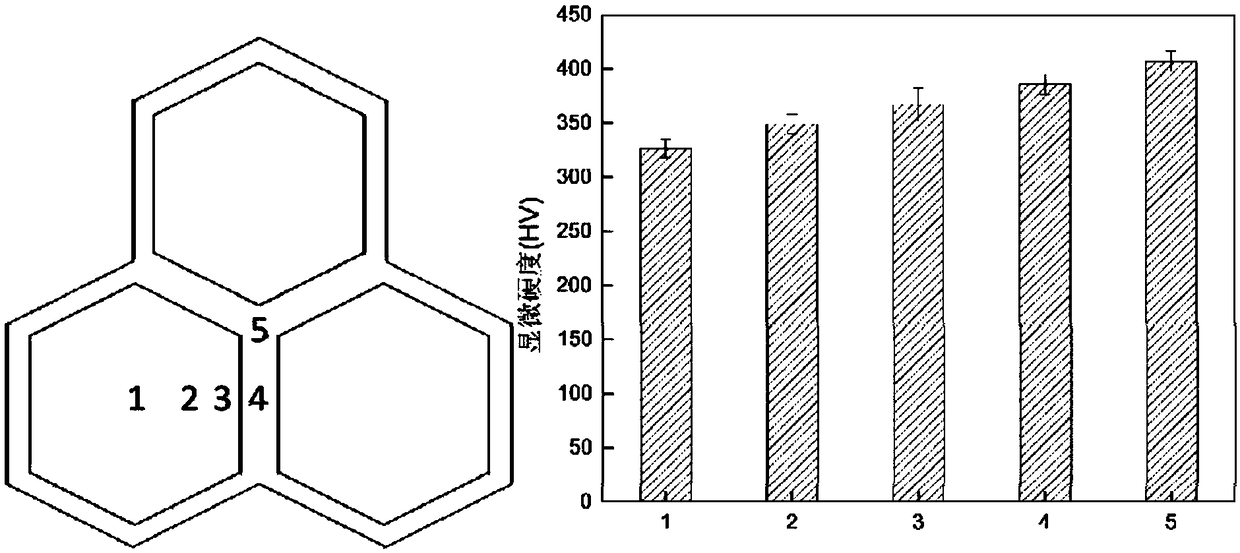

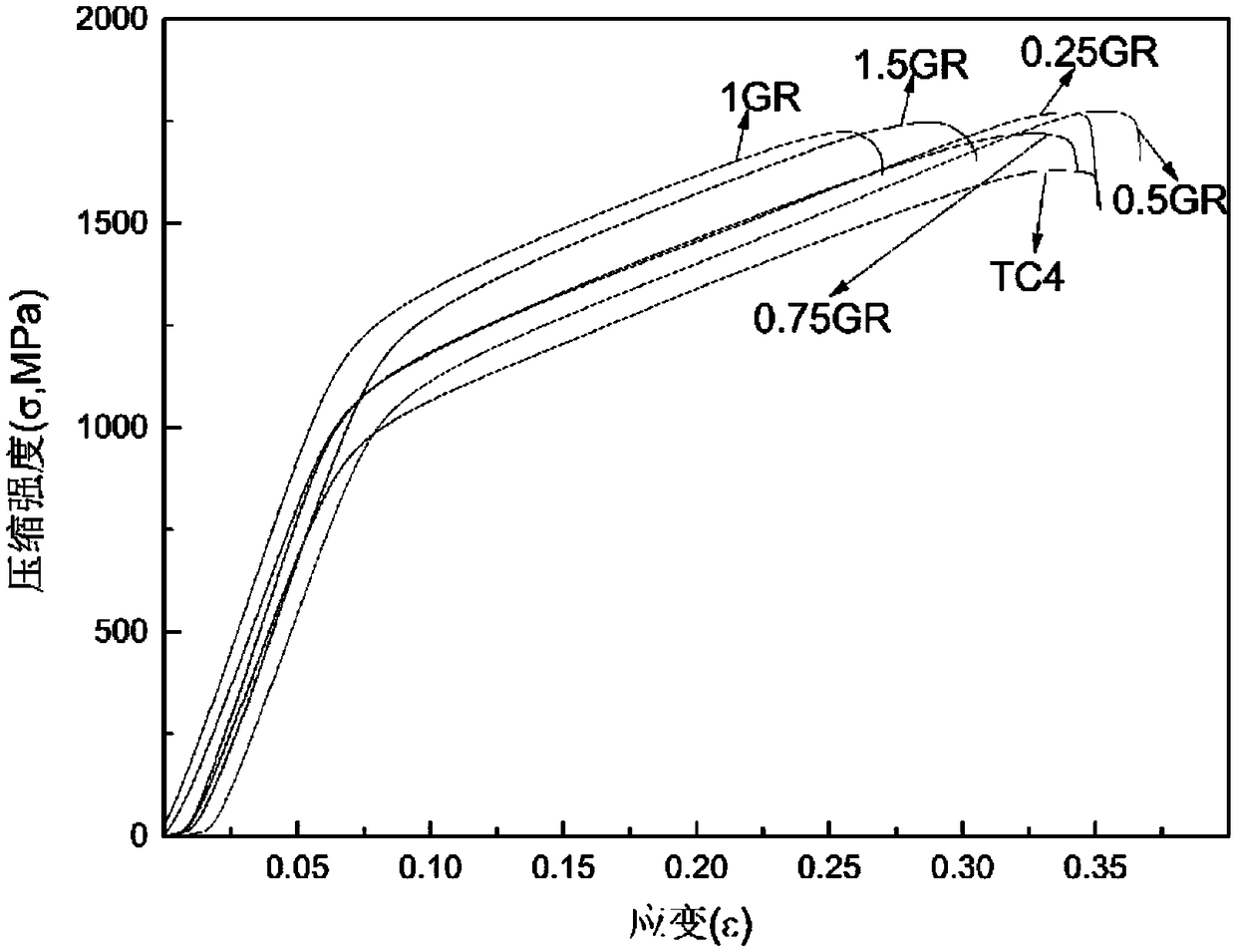

[0042] Spark plasma technology sinters to produce graphene-reinforced titanium-based composite materials, using carboxylated graphene powder and spherical Ti6Al4V (TC4) powder as raw materials, in which the thickness of graphene sheets is 1-5nm, the diameter is 0.1-10μm, and the particle size of titanium powder is 180μm (80 mesh), nano powder and micro powder respectively. A cylindrical composite material sintered body with a diameter of 10 mm and a height of 12 mm was fabricated.

[0043] Specific steps are as follows:

[0044] (1) Weigh 2.5g of PVA powder and place it in a beaker, add deionized water, heat at 80°C for 1h with magnetic stirring to make a 5% PVA aqueous solution; weigh 10g of 180 μm TC4 powder (purity is 99%) and mass fraction 0.5wt% carboxylated graphene powder.

[0045] (2) Add TC4 powder into PVA aqueous solution, stir for 5 hours, wash with deionized water, and vacuum dry at 60°C for 2 hours. Then the TC4 powder coated with PVA is placed in a beaker, an...

Embodiment 2

[0051] Spark plasma sintering technology produces network-like graphene-reinforced titanium-based composite materials, using graphene powder and spherical pure titanium powder as raw materials (purity is 99.5%), in which graphene sheets are 5-10nm thick and 10-20μm in diameter, pure titanium powder The particle size is 250 μm. A cylindrical composite material sintered body with a diameter of 20 mm and a height of 12 mm was fabricated.

[0052] Specific steps are as follows:

[0053] (1) Weigh 5g of PVA powder and place it in a beaker, add deionized water, heat at 80°C and stir magnetically for 3h to make a PVA aqueous solution with a mass fraction of 3%; weigh 20g of 106 μm pure titanium powder (purity is 99%) and mass Carboxylated graphene powder with a fraction of 1 wt%.

[0054] (2) Add pure titanium powder into PVA aqueous solution, stir for 3 hours, wash with deionized water, and vacuum dry at 60° C. for 2 hours. Then the pure titanium powder coated with PVA is placed ...

Embodiment 3

[0060]Hot-pressing sintering technology produces network graphene-reinforced titanium-based composite materials. Graphene powder and irregular titanium-nickel alloy powder are used as raw materials. The size is 13 μm (1000 mesh), and a cylindrical composite material sintered body with a diameter of 30 mm and a height of 20 mm is produced. Specific steps are as follows:

[0061] (1) Weigh 5g of PVA powder and place it in a beaker, add deionized water, heat at 100°C for 3h with magnetic stirring to make a PVA aqueous solution with a mass fraction of 10%; weigh 70g of 13 μm titanium-molybdenum powder (purity is 99.5%) and mass fraction It is 1.5wt% carboxylated graphene powder.

[0062] (2) Add titanium-molybdenum powder into PVA aqueous solution, stir for 12 hours, wash with deionized water, and vacuum-dry at 60° C. for 3 hours. Then put the titanium-molybdenum powder coated with PVA in a beaker, add 30ml of acetone to form a uniform dispersion; put the graphene powder with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com