Preparation method of corrosion-resistant high-strength AlCoCrFeNi-Cu high-entropy alloy

A high-entropy alloy and high-strength technology, which is applied in the field of preparation of corrosion-resistant and high-strength AlCoCrFeNi-Cu high-entropy alloys, can solve the problems of reducing material strength, prone to corrosion, and deteriorating the corrosion resistance of alloys, and achieves excellent corrosion resistance. , The corrosion resistance is better than the effect of eliminating macrosegregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

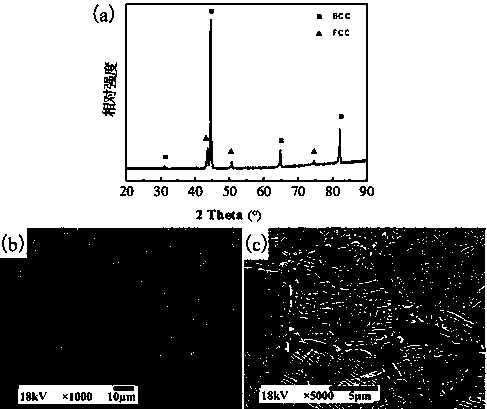

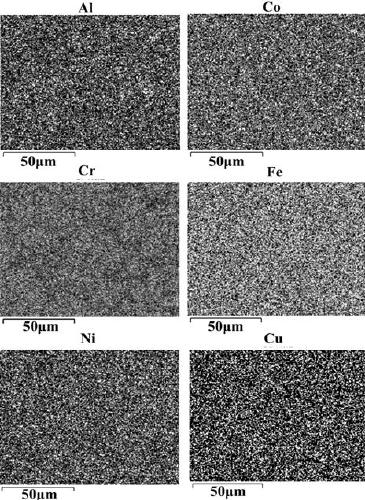

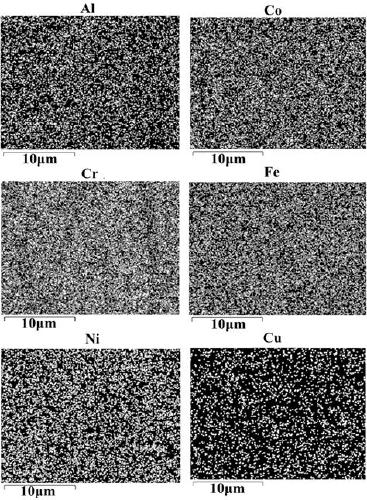

Embodiment 1

[0028] AlCoCrFeNi alloy is an atomized alloy powder, spherical, with a particle size of less than 30 μm; copper is an electrolytic powder, dendritic, with a particle size of 20-50 μm.

[0029] High-energy ball milling: According to the mass percentage of Cu being 11.18% and the balance of AlCoCrFeNi high-entropy alloy, respectively weigh copper powder and AlCoCrFeNi high-entropy alloy powder, and put them into a WC ball mill jar, WC balls are used as grinding balls, and the ball-to-material ratio is 5 : 1, then mixed for 15 h at a speed of 300 r / min under argon protection to obtain a homogeneously mixed original powder product.

[0030] Liquid-phase assisted SPS sintering: put the mixed powder into the graphite mold, and then place it in the SPS discharge plasma sintering furnace for sintering. The sintering parameters are: the vacuum degree is lower than 5×10 -3 Pa, liquid phase assisted sintering temperature 1150 ºC, applied pressure 30MPa, holding time 5 min, after sinteri...

Embodiment 2

[0034] AlCoCrFeNi alloy is an atomized alloy powder, spherical, with a particle size of less than 30 μm; copper is an electrolytic powder, dendritic, with a particle size of 20-50 μm.

[0035] High-energy ball milling: According to the mass percentage of Cu as 10% and the balance of AlCoCrFeNi high-entropy alloy, respectively weigh copper powder and AlCoCrFeNi high-entropy alloy powder, and put them into a WC ball mill jar, WC balls are used as grinding balls, and the ball-to-material ratio is 10 :1, and then mixed for 30 h under argon protection at a speed of 500 r / min to obtain a homogeneously mixed original powder product.

[0036] Liquid-phase assisted SPS sintering: put the mixed powder into the graphite mold, and then place it in the SPS discharge plasma sintering furnace for sintering. The sintering parameters are: the vacuum degree is lower than 5×10 -3 Pa, liquid phase assisted sintering temperature 1220 ºC, applied pressure 40MPa, holding time 8 min, after sintering...

Embodiment 3

[0040] AlCoCrFeNi alloy is an atomized alloy powder, spherical, with a particle size of less than 30 μm; copper is an electrolytic powder, dendritic, with a particle size of 20-50 μm.

[0041] High-energy ball milling: According to the mass percentage of Cu as 20% and the balance of AlCoCrFeNi high-entropy alloy, respectively weigh Cu powder and AlCoCrFeNi high-entropy alloy powder, and put them into a WC ball mill jar, WC balls are used as grinding balls, and the ball-to-material ratio is 6 : 1, and then mixed for 20 h under argon protection at a speed of 400 r / min to obtain a homogeneously mixed original powder product.

[0042] Liquid-phase assisted SPS sintering: put the mixed powder into the graphite mold, and then place it in the SPS discharge plasma sintering furnace for sintering. The sintering parameters are: the vacuum degree is lower than 5×10 -3 Pa, liquid phase assisted sintering temperature 1120 ºC, applied pressure 30MPa, holding time 4 min, after sintering, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current | aaaaa | aaaaa |

| Compression breaking strength | aaaaa | aaaaa |

| Corrosion current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com