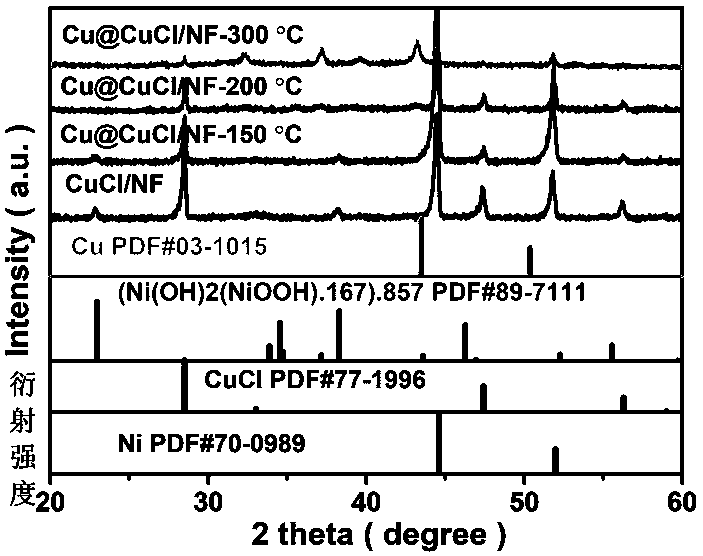

Preparation method and application of cuprous chloride/nickel foam composites with surface modified by metallic copper

A technology of cuprous chloride and surface metal, applied in the field of electrochemistry, to achieve the effect of simple and easy operation process, short reaction time, and easy industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

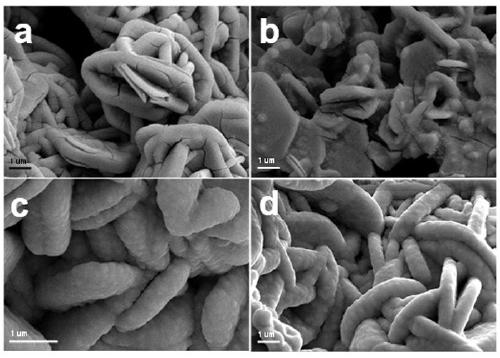

Embodiment 1

[0029] Comparative test, including the following steps:

[0030] Step 1: Sonicate the cut NF with a size of 1 cm×1 cm in acetone and absolute ethanol for 30 minutes, and then in deionized water for 3 times, 20 minutes each time, and finally soak in deionized water for use.

[0031] Step 2: Prepare 8.5% CuCl with deionized water 2 The solution, namely solution A, was transferred to the beaker where the solution A was placed in a refrigerator set at 5°C and allowed to stand for 30 minutes.

[0032] Step 3: Put the NF soaked in deionized water into solution A and continue to stand in the refrigerator at 5 °C for 2 hours, then take out the NF and soak it in deionized water and absolute ethanol for 3 times respectively, and finally put it under normal temperature Dry to obtain CuCl / NF composite material.

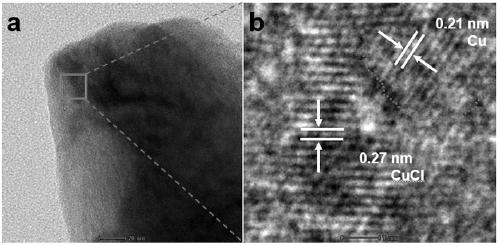

Embodiment 2

[0034] A preparation method for surface metal copper modified cuprous chloride / nickel foam composite material, comprising the steps of:

[0035] Step 1: Sonicate the cut NF with a size of 1 cm×1 cm in acetone and absolute ethanol for 30 minutes, and then in deionized water for 3 times, 20 minutes each time, and finally soak in deionized water for use.

[0036] Step 2: Prepare 8.5% CuCl with deionized water 2 The solution, namely solution A, was transferred to the beaker where the solution A was placed in a refrigerator set at 5°C and allowed to stand for 30 minutes.

[0037] Step 3: Put the NF soaked in deionized water into solution A and continue to stand in the refrigerator at 5 °C for 2 hours, then take out the NF and soak it in deionized water and absolute ethanol for 3 times respectively, and finally put it under normal temperature Dry to obtain CuCl / NF composite material.

[0038] Step 4: Place the CuCl / NF composite in a semi-closed porcelain boat and transfer it to a ...

Embodiment 3

[0040] A preparation method for surface metal copper modified cuprous chloride / nickel foam composite material, comprising the steps of:

[0041] Step 1: Sonicate the cut NF with a size of 1 cm×1 cm in acetone and absolute ethanol for 30 minutes, then in deionized water for 3 times, 20 minutes each time, and finally soak in deionized water for use.

[0042] Step 2: Prepare 8.5% CuCl with deionized water 2 The solution, namely solution A, was transferred to the beaker where the solution A was placed in a refrigerator set at 5°C and allowed to stand for 30 minutes.

[0043] Step 3: Put the NF soaked in deionized water into solution A and continue to stand in the refrigerator at 5 °C for 2 hours, then take out the NF and soak it in deionized water and absolute ethanol for 3 times, and finally put it under normal temperature Dry to obtain CuCl / NF composite material.

[0044] Step 4: Place the CuCl / NF composite in a semi-closed porcelain boat and transfer it to a temperature-progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com