Preparation method of NiCoP@graphene aerogel efficient hydrogen evolution composite material

A technology of graphene airgel and composite materials, which is applied in the field of material synthesis, can solve the problems of pollution and electrochemical hydrogen evolution, which are rarely reported, and achieve good hydrophilicity, improve the hydrogen evolution performance of electrolyzed water, and excellent electrochemical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

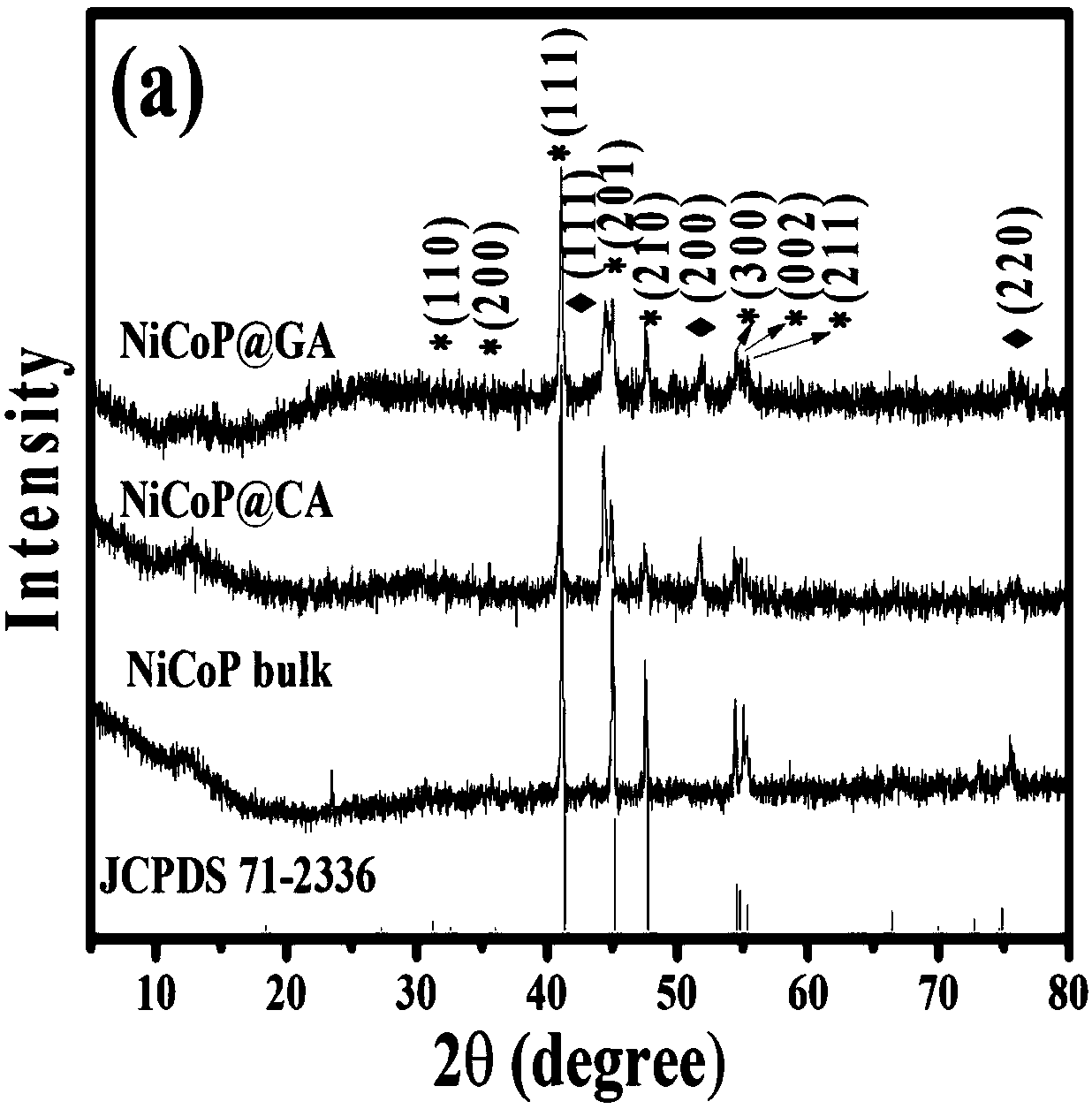

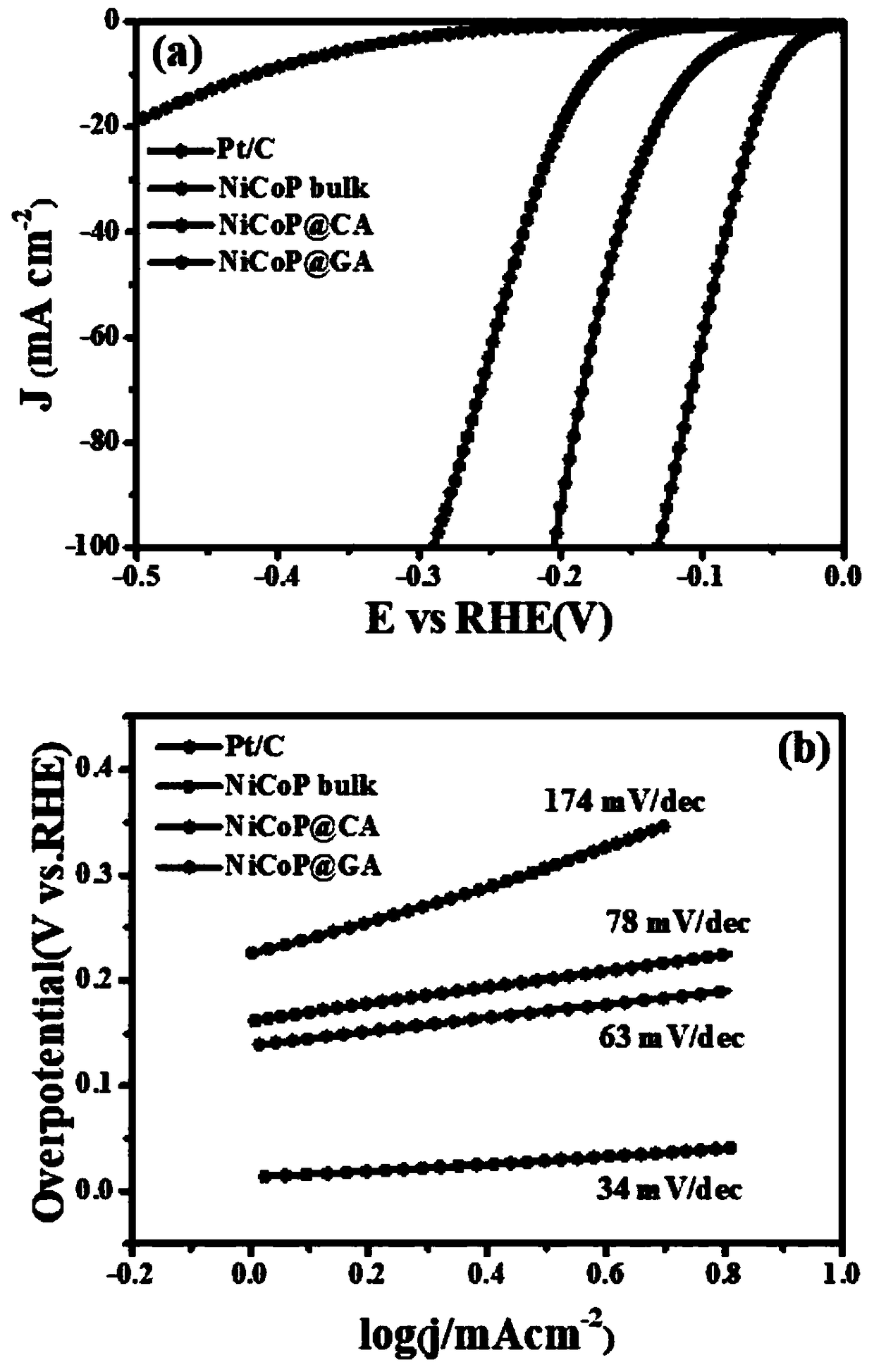

[0030] Preparation of NiCoP bulk material

[0031] (1) Weigh 0.5g Co(NO 3 ) 2 ·6H 2 O and 0.5g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 40ml deionized water and stirred to form Co(NO 3 ) 2 ·6H 2 O and Ni(NO 3 ) 2 ·6H 2 O mixed solution A.

[0032] (2) Weigh 20 mmol of NaOH solid and dissolve it in 10 ml of deionized water, and stir for 10 min to form a homogeneous solution B.

[0033](3) Add solution B drop by drop into solution A, stir for 10 min, wait until the reaction is complete, then centrifuge, wash, dry and grind the precipitate to form a gray powder.

[0034] (4) Take 0.4g of gray powder and 0.5g of red phosphorus (P) respectively, red phosphorus is placed in the upstream of the tube furnace, the gray powder of the precursor is placed in the downstream, nitrogen is used as the protective gas, the calcination temperature is 800°C, and the holding time is For 4 h, the heating rate is 4 °C / min, high-temperature phosphating is carried out, and finally the NiCoP b...

Embodiment 2

[0036] Preparation of NiCoP@Carbon Airgel (NiCoP@CA) Efficient Hydrogen Evolution Composite

[0037] (1) Weigh 0.5g Co(NO 3 ) 2 ·6H 2 O and 0.5g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 40ml deionized water and stirred to form Co(NO 3 ) 2 ·6H 2 O and Ni(NO 3 ) 2 ·6H 2 O mixed solution A;

[0038] (2) Weigh 0.4g of sodium alginate (SA) and pour it into 40ml of ionized water and stir vigorously to form a uniform sodium alginate solution B;

[0039] (3) A certain volume of solution B is dripped into solution A at room temperature to form a hydrogel. The formed hydrogel was aged for 8 hours, then soaked in deionized water and washed 3 times for 2 hours each time; soaked in ethanol and washed 3 times for 2 hours each time.

[0040] (4) Freeze-dry the aged, soaked and washed hydrogel in a freeze dryer for 48 hours until a xerogel is formed.

[0041] (5) Take 0.4g of xerogel and 0.5g of red phosphorus (P) respectively, red phosphorus is placed in the upstream position of th...

Embodiment 3

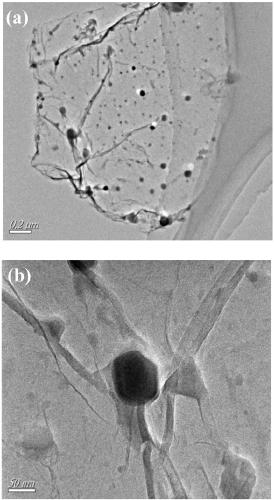

[0043] Preparation of NiCoP@Graphene Carbon Airgel (NiCoP@GA) High Efficiency Hydrogen Evolution Composite

[0044] (1) Weigh 0.5g Co(NO 3 ) 2 ·6H 2 O and 0.5g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 40ml deionized water and stirred to form Co(NO 3 ) 2 ·6H 2 O and Ni(NO 3 ) 2 ·6H 2 O mixed solution A;

[0045] (2) Weigh 0.4g of sodium alginate (SA) and pour it into 40ml of ionized water and stir vigorously to form a uniform sodium alginate solution B;

[0046] (3) Weigh 80 mg of GO powder and inject it into solution B, and after stirring, sonicate in an ultrasonic instrument for 30 minutes to obtain dispersion C;

[0047] (4) Add 40ml of solution C dropwise into solution A at room temperature to form a hydrogel. The formed hydrogel was aged for 8 hours, then soaked in deionized water and washed 3 times for 2 hours each time; soaked in ethanol and washed 3 times for 2 hours each time.

[0048] (5) Freeze-dry the aged, soaked and washed hydrogel in a freeze dryer for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com