Corrosion method of gallium germanium arsenide single crystal dislocation pit and corrosion solution formula

A technology of gallium arsenide and corrosion solution, which is applied in the field of chemical technology, can solve the problems of too large, fragile and cracked corrosion loss of the wafer to be tested, and achieve the effects of low corrosion loss, reducing stress concentration, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

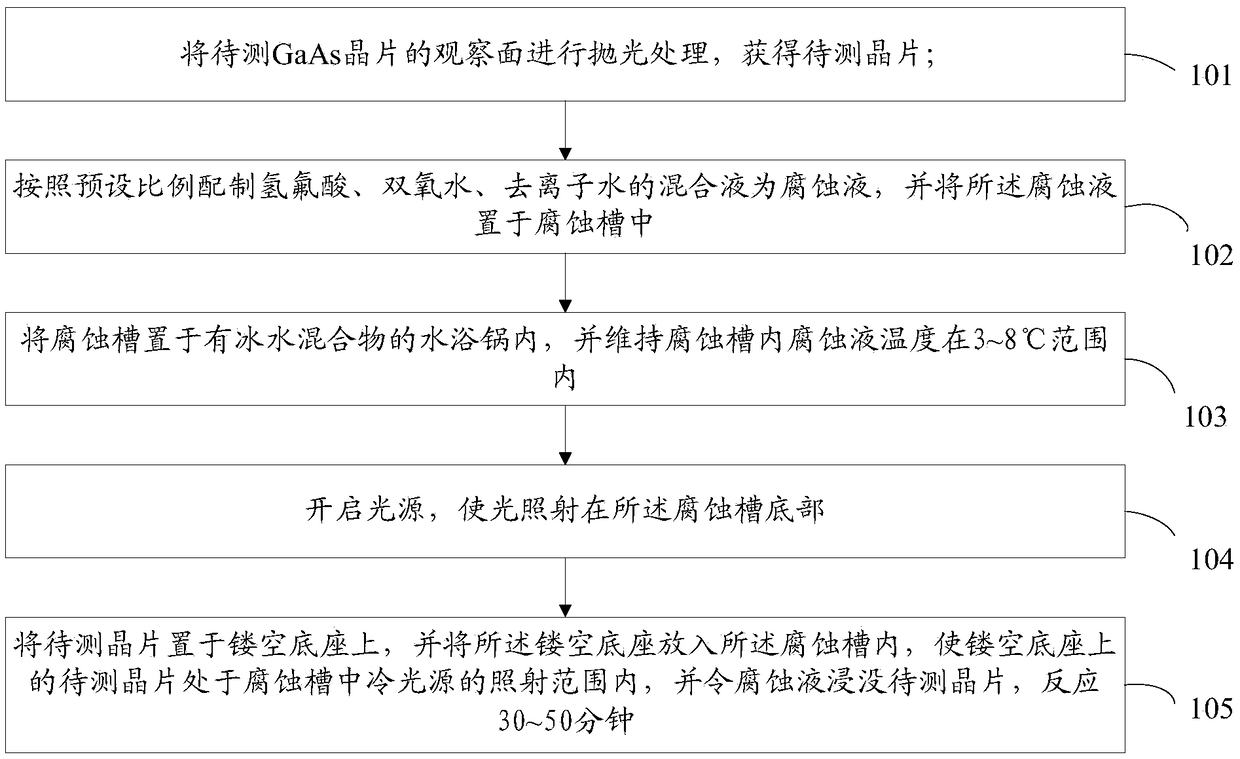

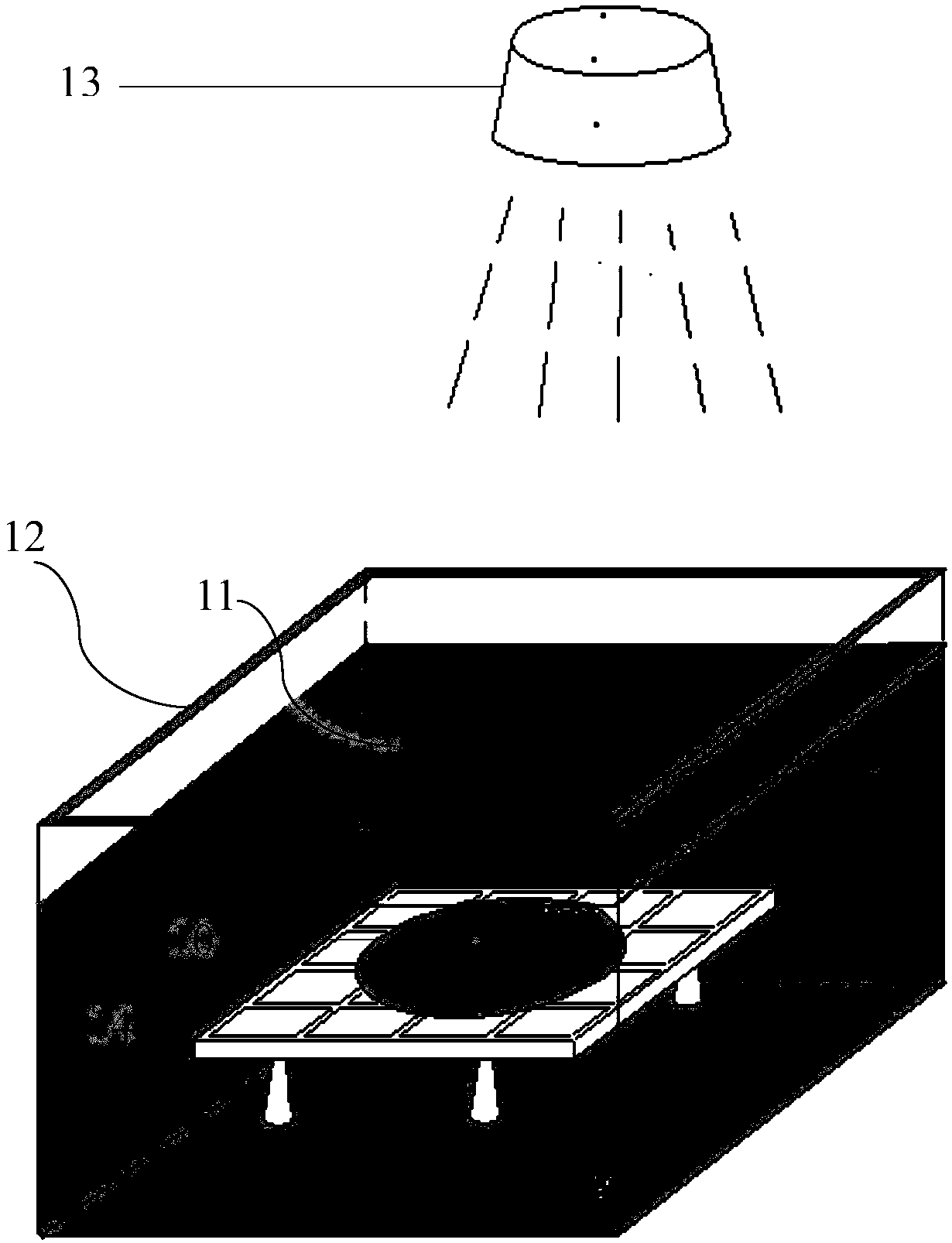

[0027] refer to figure 1 , showing a step-by-step flowchart of a GaAs single crystal dislocation pit etching method, combined with figure 2 The schematic diagram of the framework shown, the specific steps of this application include:

[0028] Step 101: Polishing the observation surface of the GaAs wafer to be tested (10) to obtain the wafer to be tested.

[0029] Optionally, the GaAs single crystal material includes n-type GaAs doped with Si (Si, silicon) semiconductor, p-type GaAs doped with Zn (Zn, zinc) semiconductor, GaAs doped with C (C, carbon) semi-insulating semiconductor and other GaAs Single crystal materials, as long as the main body is a GaAs single crystal material, can be used in this solution, and the present invention does not limit the specific type of GaAs single crystal material.

[0030] In a specific application, the embodiments of the present invention can use professional polishing equipment to mechanically polish the GaAs wafer (10) to be tested, or ...

Embodiment 2

[0056] The invention provides a corrosive liquid formula, comprising:

[0057] The corrosion solution is obtained by mixing hydrofluoric acid, hydrogen peroxide and deionized water.

[0058] Optionally, the volume ratio of hydrofluoric acid, hydrogen peroxide and deionized water in the corrosion solution is (2-8):(0.5-2):(88-97).

[0059] For example, the proportion of the corrosion solution can be prepared by mixing hydrofluoric acid, hydrogen peroxide, and deionized water with a volume ratio of 2:0.5:88, or it can be prepared by mixing hydrofluoric acid, hydrogen peroxide, and deionized water with a volume ratio of 8:2:97. Ionized water is mixed and prepared, or prepared in proportion to any value within the corresponding ranges of hydrofluoric acid, hydrogen peroxide, and deionized water (2-8): (0.5-2): (88-97).

[0060] Preferably, the volume ratio of hydrofluoric acid, hydrogen peroxide and deionized water in the mixed liquid is 5:1:94.

[0061] It should be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com