Preparation method for patterned photonic crystal structural coloration material with stable structure and bright color

A technology of photonic crystals and stable structures, applied in optics, optical components, instruments, etc., can solve the problems of reduced refractive index difference of photonic crystal structures, dark color, and reduced color saturation of photonic crystal structures, etc., to achieve bright structural colors, Strong structural stability, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

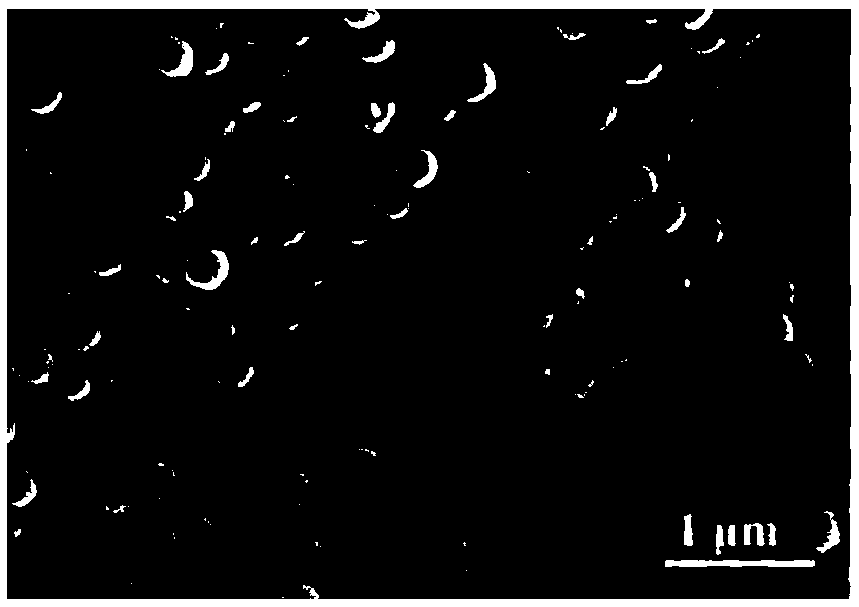

[0033] A method for preparing a patterned photonic crystal structure chromogenic material with both stable structure and bright color, the specific steps of the method are:

[0034] (1) Preparation: Put a piece of circular plain polyester fabric with a diameter of 4 cm into an ultrasonic cleaner for cleaning for 5 minutes;

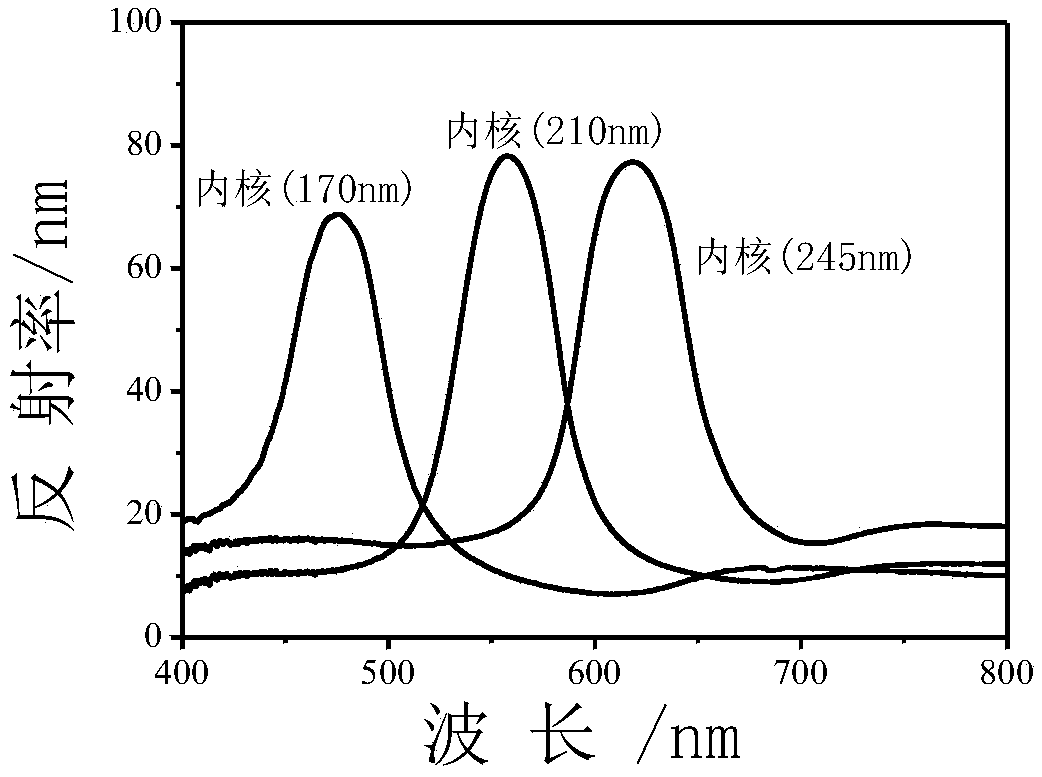

[0035] (2) Dispersing hollow silica microspheres with an inner core diameter of 400nm and a shell thickness of 100nm in water to form a colloidal dispersion with a concentration of 0.2wt%;

[0036] (3) After 10 hours of self-assembly in a constant temperature and humidity chamber at a temperature of 60 degrees Celsius and a relative humidity of 60% by using the gravity sedimentation self-assembly method, a hollow silica photonic crystal structure can be obtained on the surface of the polyester fabric substrate;

[0037] (4) Mix polyurethane diacrylate and hydroxyethyl acrylate at a mass ratio of 20:1, and then add 3% diphenyl (2,4,6-trimethylbenzoyl) phosp...

Embodiment 2

[0039] A method for preparing a patterned photonic crystal structure chromogenic material with both stable structure and bright color, the specific steps of the method are:

[0040] (1) Preparation: Put a piece of circular plain silk fabric with a diameter of 4 cm into an ultrasonic cleaning machine for cleaning for 5 minutes;

[0041] (2) Dispersing hollow silica microspheres with a core diameter of 240nm and a shell thickness of 17nm in water to form a colloidal dispersion with a concentration of 5wt%;

[0042] (3) After self-assembling for 20 hours in a constant temperature and humidity box at a temperature of 60 degrees Celsius and a relative humidity of 60% by using the vertical layered self-assembly method, a hollow silicon dioxide photonic crystal structure can be obtained on the surface of the fabric substrate;

[0043] (4) Mix polyurethane diacrylate and hydroxyethyl methacrylate at a mass ratio of 15:1, and then add 0.2% diphenyl (2,4,6-trimethylbenzoyl) Phosphine o...

Embodiment 3

[0047] A method for preparing a patterned photonic crystal structure chromogenic material with both stable structure and bright color, the specific steps of the method are:

[0048] (1) Preparation: Put a piece of circular plain nylon fabric with a diameter of 4 cm into an ultrasonic cleaner for 5 minutes;

[0049] (2) Dispersing hollow silica microspheres with an inner core diameter of 100nm and a shell thickness of 5nm in water to form a colloidal dispersion with a concentration of 10wt%;

[0050] (3) Use the vertical pulling method to vertically immerse the fabric into the colloidal dispersion liquid and slowly pull it to the liquid surface at a speed of 2mm / s and then infiltrate it. After 50 cycles, hollow silica photons can be obtained on the surface of the fabric substrate. Crystal structure.

[0051] (4) Mix polyurethane diacrylate and polyethylene glycol diacrylate at a mass ratio of 10:1, and then add 4% diphenyl (2,4,6-trimethylbenzoyl ) phosphine oxide as a photoi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com