A DC generator based on a moving Schottky junction and a preparation method thereof

A DC generator, Schottky junction technology, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the wear of nanowires and electrodes, affecting the performance and life of nanogenerators, and the failure of generators to work properly, etc. problem, to achieve the effect of less wear and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

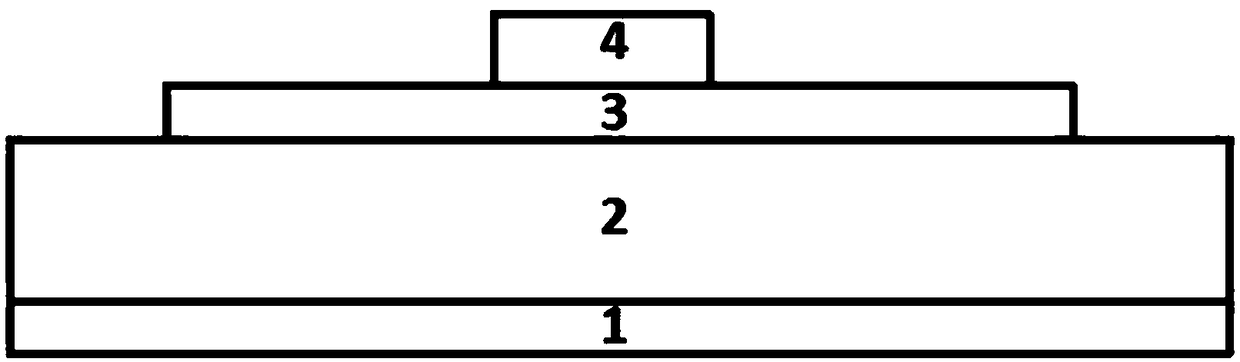

[0023] 1) Make an electrode on the back of the N-type doped silicon wafer, the material is a 100nm titanium / gold electrode, and then immerse it in acetone and isopropanol solutions to clean the surface, clean it with deionized water, take it out and dry it;

[0024] 2) Cut the graphene film to the required size, make electrodes on the front side, the material is silver paste, and then dry;

[0025] 3) Press the graphene film on the N-type silicon substrate and move each other to obtain a DC generator based on the moving Schottky junction to generate electrical signals.

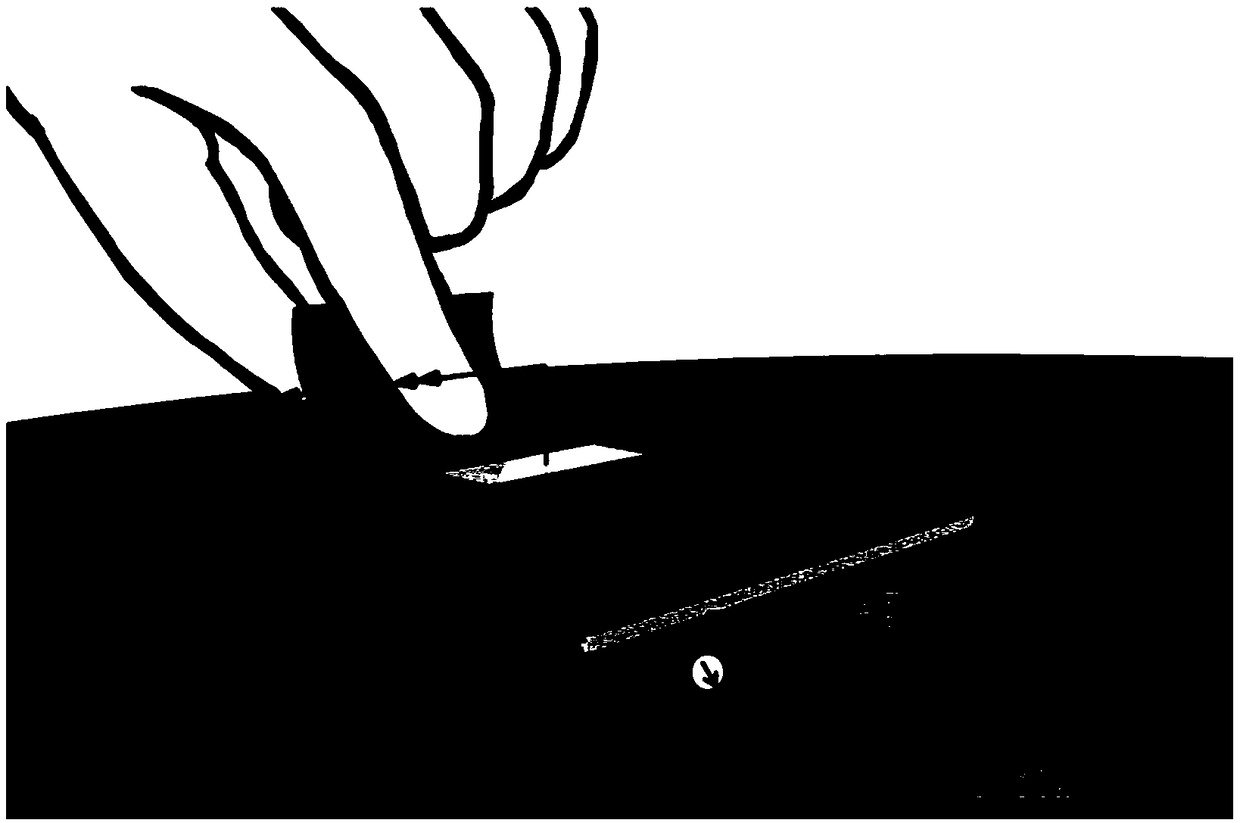

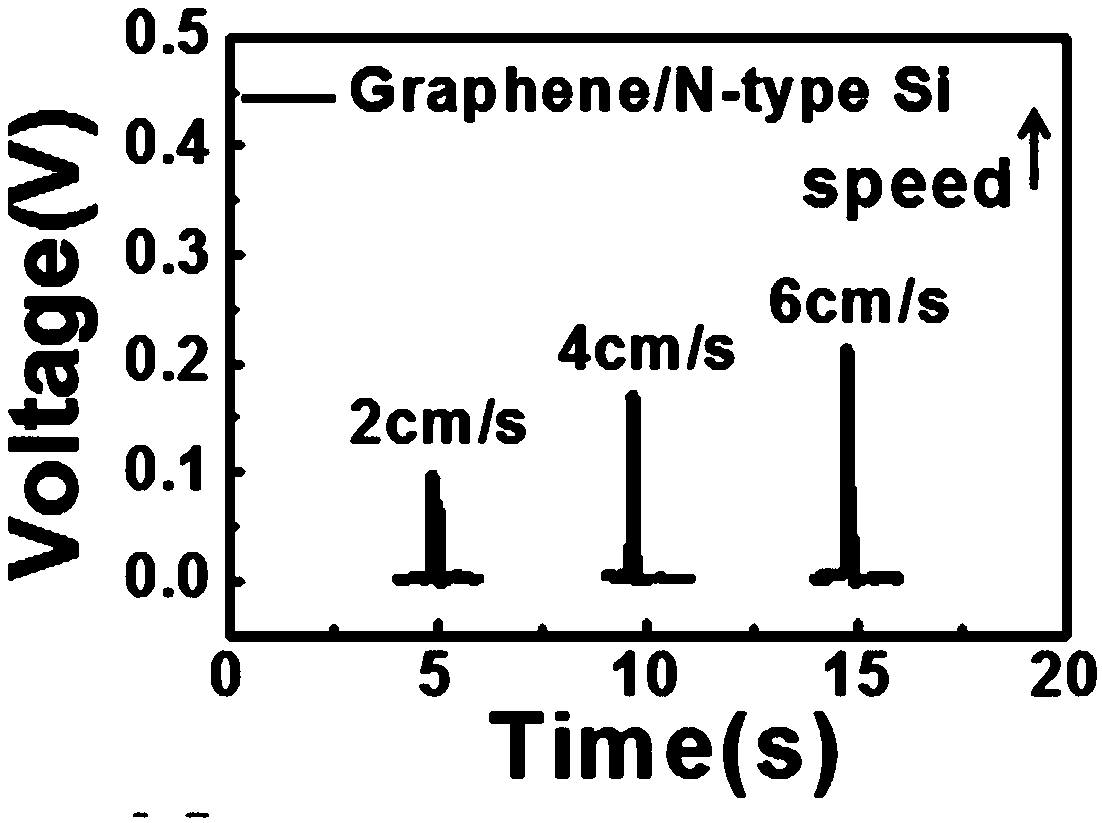

[0026] The structure schematic diagram of described graphene film / N-type silicon mobile Schottky junction direct current generator is as figure 2 shown. Move the graphene film on the silicon surface by hand, and an electrical signal can be obtained at both ends of the electrode, and the resulting voltage is about 0.2V. like image 3 As shown, the size of the output voltage is related to the speed, the grea...

Embodiment 2

[0028] 1) Make an electrode on the back of the N-type doped silicon wafer, the material is a 100nm titanium / gold electrode, and then immerse it in acetone and isopropanol solutions to clean the surface, clean it with deionized water, take it out and dry it;

[0029] 2) Cut the aluminum film to the required size, and make electrodes on the front, made of copper wire;

[0030] 3) Press the aluminum film on the N-type silicon substrate and move it with each other to obtain a DC generator based on the moving Schottky junction to generate electrical signals.

[0031] For the aluminum film / N-type silicon mobile Schottky junction DC generator, you only need to move the aluminum film on the silicon surface by hand, and you can get electrical signals at both ends of the electrodes, and the generated voltage is about 0.6V, such as Figure 4 shown.

Embodiment 3

[0033] 1) Make an electrode on the back of the N-type doped gallium arsenide chip, the material is a 100nm titanium / gold electrode, and then immerse it in acetone and isopropanol solutions to clean the surface, clean it with deionized water, take it out and dry it;

[0034] 2) Cut the aluminum film to the required size, and make electrodes on the front, made of copper wire;

[0035] 3) Press the aluminum film on the N-type gallium arsenide substrate and move each other to obtain a DC generator based on the moving Schottky junction to generate electrical signals.

[0036] The continuous power generation structure of the aluminum film / N-type gallium arsenide mobile Schottky junction DC generator is set as Figure 5 As shown, only need to keep moving the aluminum film on the surface of gallium arsenide, the electrical signal can be obtained at both ends of the electrodes, and a continuous DC signal with a voltage of about 0.5V is generated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com